Ion beam automatic measuring system and method

An automatic measurement, ion beam technology, applied in measurement devices, radiation measurement, X / γ / cosmic radiation measurement and other directions, can solve the problem of large loss of ion source and parameter measurement device, affecting the stability of the ion source system, laborious and other problems , to achieve the effect of being conducive to maintenance, saving measurement time and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

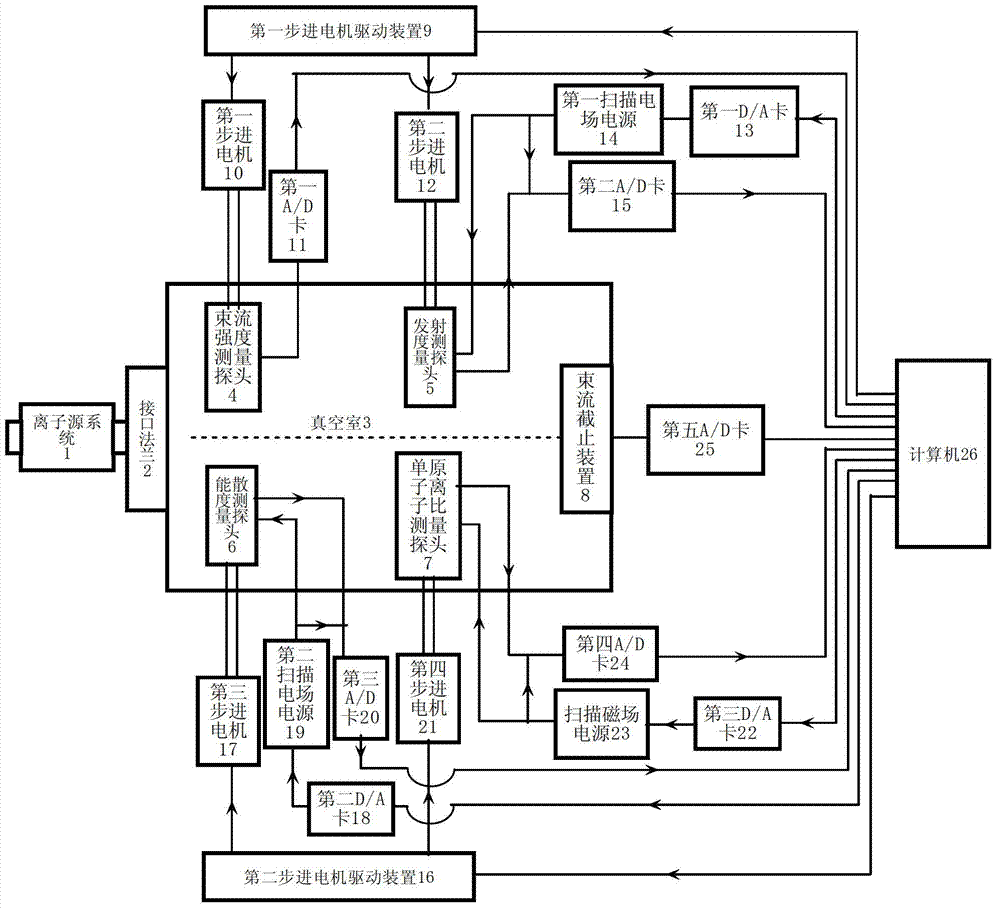

[0027] Such as figure 1 As shown, an ion beam automatic measurement system according to an embodiment of the present invention includes: an ion source system 1, an interface flange 2, a vacuum chamber 3, a beam intensity measurement probe 4, an emissivity measurement probe 5, and an energy divergence measurement probe 6 , monoatomic ion ratio measuring probe 7, beam cut-off device 8, first stepper motor driver 9, second stepper motor driver 16, first stepper motor 10, second stepper motor 12, third step Advance motor 17, the 4th stepper motor 21, the first scanning electric field power supply 14, the second scanning electric field power supply 19, scanning magnetic field power supply 23, the first A / D card 11, the second A / D card 15, the third A / D card D card 20, the 4th A / D card 24, the 5th A / D card 25, the first D / A card 13, the second D / A card 18, the 3rd D / A card 22 and computer 26; Ion beam current After being drawn out from the ion source system 1, the interface flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com