3G (the third generation telecommunication) network based remote dental air circuit diagnosing and monitoring system

A technology of remote diagnosis and monitoring system, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as no mention, avoid unnecessary losses, prevent fault omission, and achieve high fault diagnosis rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

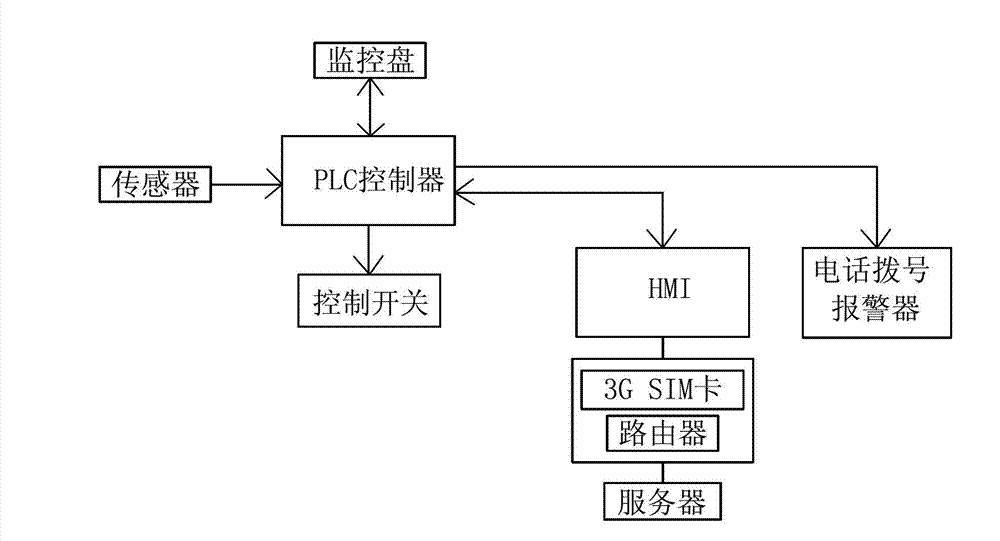

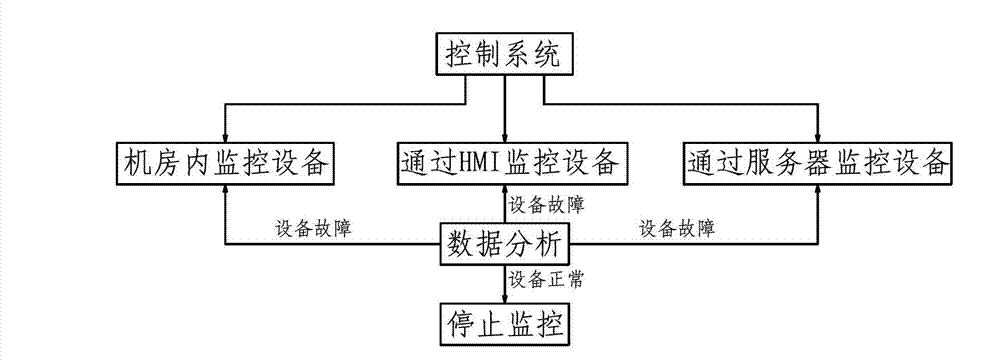

[0023] Such as figure 1 , figure 2 As shown, the 3G network-based dental air circuit remote diagnosis and monitoring system includes a control system set on the dental air circuit equipment, which is characterized in that: the control system includes a PLC controller, a monitoring panel, a control switch and a sensor; the monitoring panel is connected to the PLC The controller, the input end of the PLC controller is connected to the sensor, the output end of the PLC controller is connected to the control switch, the sensor is set to collect information on the dental gas circuit equipment, the monitoring panel inputs the control parameters, displays the operating data, and monitors the dental gas in the machine room. The communication terminal of the PLC controller is connected to the human-machine interface HMI through the cable connection, and the HMI obtains and modifies various working parameters and alarm parameters of the dental gas circuit equipment, and controls the de...

Embodiment 2

[0073] On the basis of Embodiment 1, the control system also includes a camera and a processor. The output end of the camera is connected to the processor, and the communication end of the processor is connected to a router to collect and upload real-time status video of the dental gas circuit equipment. Real-time status video is provided. On the premise of data reminder, maintenance personnel can obtain more detailed information. In addition to status data, faults can also be judged based on video records and ready-made videos, improving fault diagnosis rate and shortening maintenance time.

[0074] Working principle and usage process:

[0075] The control system of air compressor and vacuum pump is connected with the router installed with 3G SIM card, and all parameters of the equipment can be obtained through communication. By accessing the 3G SIM card through the server, the air compressor and vacuum pump can be remotely diagnosed and monitored through the wireless network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com