Tele-manipulating robot force feedback control system and control method thereof

A feedback control system and remote operation technology, applied in the direction of control/adjustment system, mechanical pressure/force control, non-electric variable control, etc., can solve the problem of reduced detection accuracy, easy wear of sensors, and difficulty in developing fully autonomous intelligent robots, etc. problem, to achieve the effect of convenient modeling, easy control method, and avoiding the reduction of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

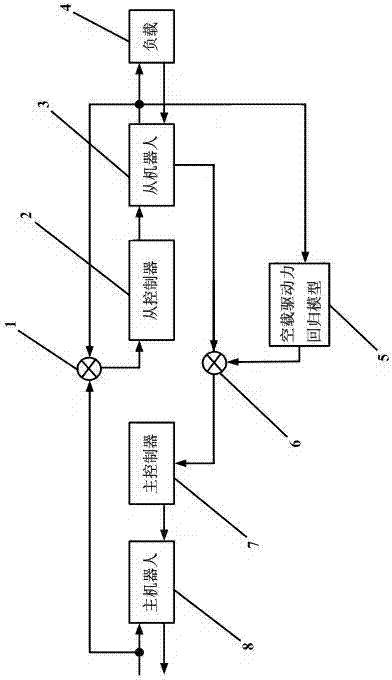

[0022] The principle diagram of the present invention is as figure 1 As shown, the teleoperated robot force feedback control system of the present invention includes a position comparator 1, a slave controller 2, a slave robot 3, a load 4, a no-load driving force regression model 5, a force comparator 6, and a master controller 7 , Master robot 8, position comparator 1 outputs master-slave position error signal to slave controller 2, slave controller 2 outputs control amount after control operation to control slave robot 3 to drive load 4, no-load driving force regression model 5 online identification output the no-load driving force, the force comparator 6 transmits the force difference signal between the force driving the load 4 and the no-load driving force output by the no-load driving force regression model 5 to the main controller 7, and the main controller 7 outputs the control amount to the main controller The robot 8 is made to generate a feedback force acting on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com