Low temperature circuit breaker body

A circuit breaker body and low temperature technology, applied in the field of low temperature circuit breaker body, can solve the problems of high manufacturing cost of circuit breaker body, large amount of sulfur hexafluoride gas, increased manufacturing cost, etc., achieve compact structure, low manufacturing cost, reduce The effect of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

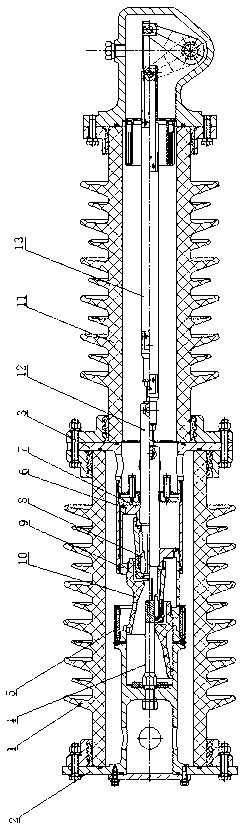

[0008] Such as figure 1 As shown, the low temperature circuit breaker body includes an arc extinguishing chamber and a pillar chamber.

[0009] The arc extinguishing chamber mainly includes an arc extinguishing chamber porcelain sleeve 1, a static contact assembly, a moving contact assembly, a nozzle 10 and a pressure cylinder 6. The static terminal block 2 and the dynamic terminal block 3 are respectively installed at both ends of the porcelain sleeve 1 of the arc extinguishing chamber, and the static contact assembly and the dynamic contact assembly are arranged in the porcelain sleeve 1 of the arc extinguishing chamber, and the static contact assembly is installed on the static terminal block 2 , which includes a static arc contact 4 and a static main contact 5, the static arc contact 4 is installed in the center of the inner end of the static wire seat 2, and the static main contact 5 is installed in the circumferential direction of the inner end of the static wire seat 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com