Connector

A technology of connectors and connecting caps, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve problems such as hidden dangers of personal safety of operators, and achieve the effect of increasing separation time and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

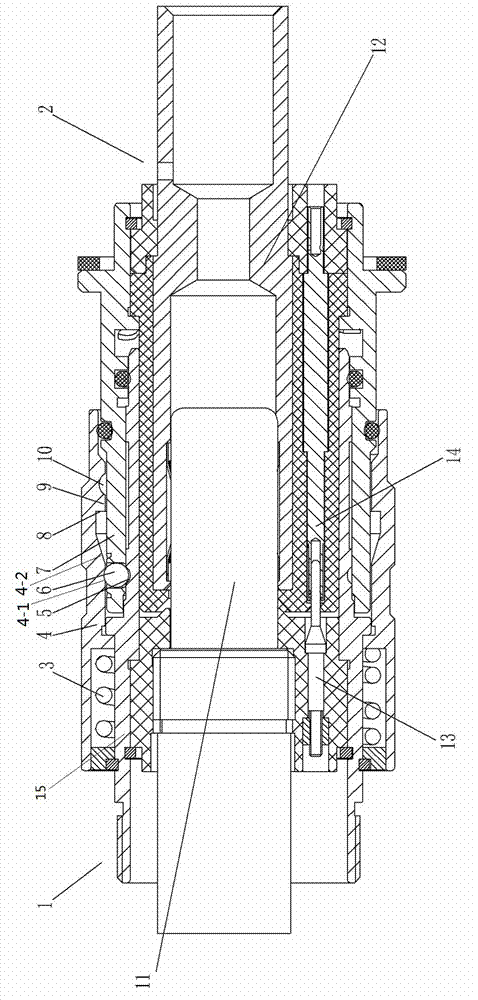

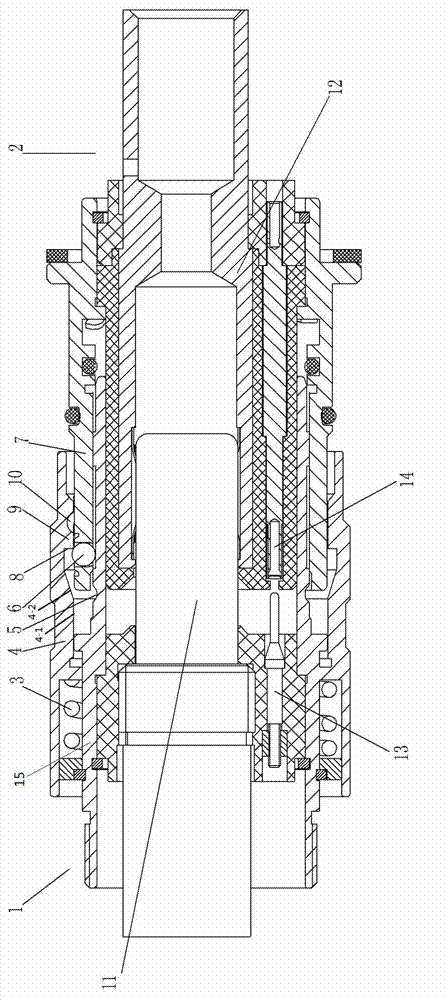

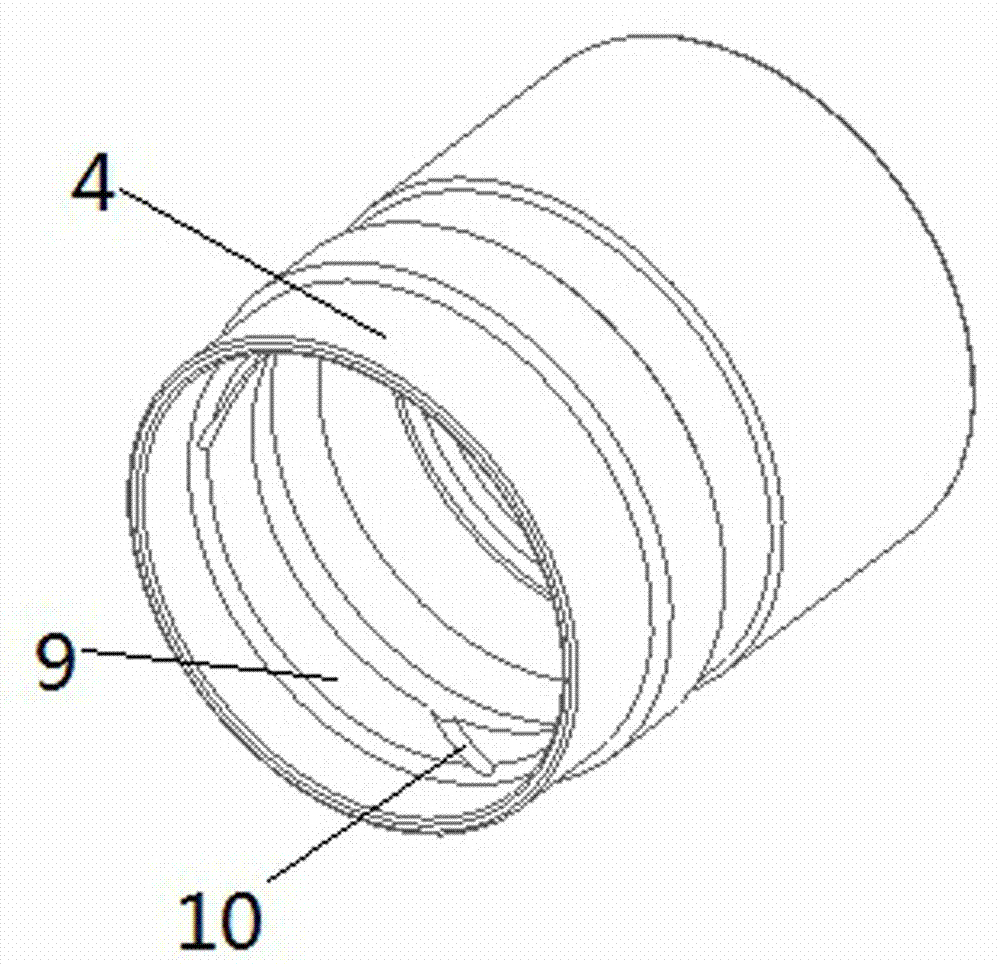

[0019] Examples of connectors are Figure 1~3 As shown: it includes a plug 1 and a socket 2 with the front end as a plug-in terminal. The plug 1 includes a plug housing 15 and a plug main contact 11 and a plug signal contact 13 assembled in the plug housing 15. The socket 2 includes a socket housing 7 And socket main contacts 12 and socket signal contacts 14 assembled in the socket housing 7 . The outer circumference of the plug housing 15 is equipped with a connecting cap 4 for the anti-off rotation of the axial direction, and an annular gap is arranged between the inner wall of the connecting cap 4 and the outer wall of the plug housing 15, and the front end of the socket housing 7 is inserted into the annular gap when connecting. There are three floating locking balls 6 evenly distributed on the socket connecting end in the circumferential direction, and the floating locking balls 6 have an outer convex part protruding from the outer peripheral surface of the socket housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com