High-strength iron gauze weaving machine

A barbed wire, high-strength technology, applied to wire netting, other household appliances, household appliances, etc., can solve the problems of surface damage, poor straightening effect of high-strength wire, and reduced tensile strength, so as to prolong the service life and facilitate adjustment Fast, prevents knotting or breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

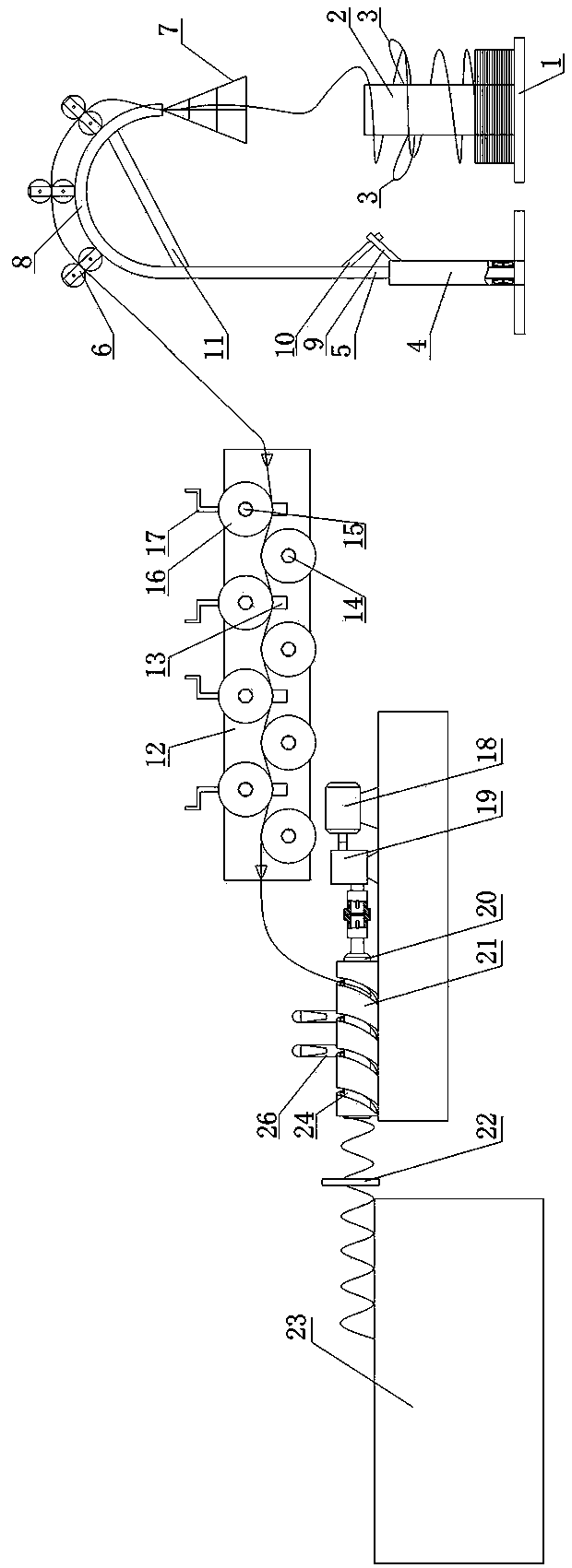

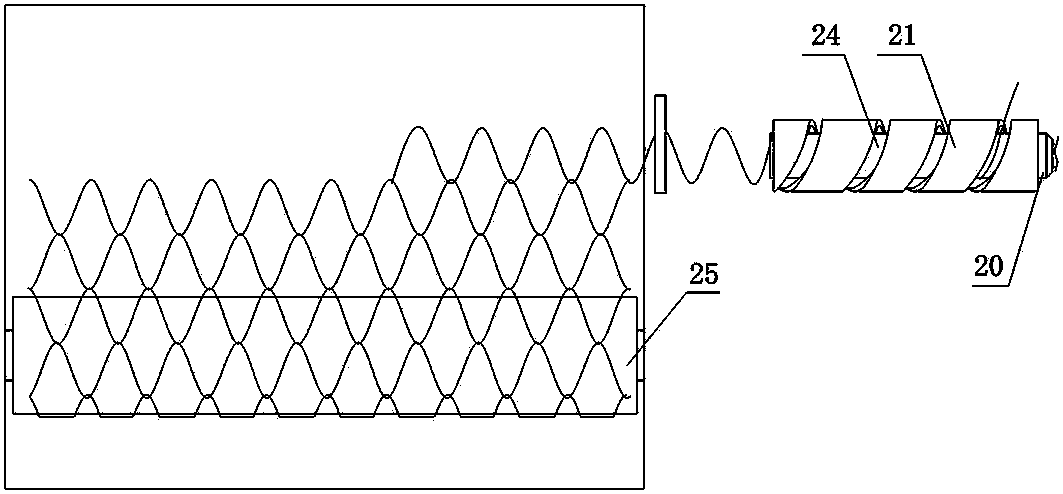

[0022] Such as figure 1 As shown, the high-strength barbed wire weaving machine includes an unwinding device, a guiding device, a straightening device and a forming weaving device arranged in sequence, and the unwinding device includes a supporting base 1 and a column arranged on the supporting base 1 2. The upper part of the column 2 is provided with a wire retaining ring 3. The wire retaining ring 3 is a metal wire fixed on the column 2 at both ends. The blocking effect of the iron wire can prevent the multi-circle iron wire from being pulled up at the same time due to interlacing and intersecting each other, resulting in knotting, ensuring orderly and smooth wire feeding.

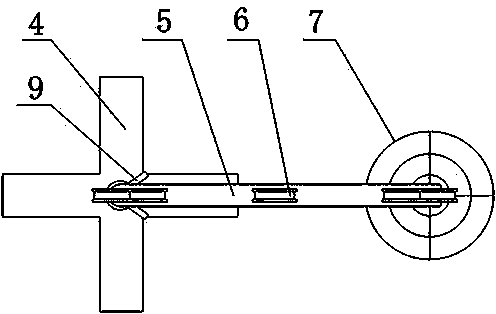

[0023] Described guiding device comprises base 4, support 5, guide wheel 6 and guide cover 7, and base 4 is fixed on the gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com