Processing method of four-station concave die

A processing method and four-station technology, which is applied in the field of die processing, can solve the problems of unsatisfactory service life and quality of four-station dies, and achieve the effects of shortening cooling time, improving surface roughness, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The processing method of the four-station die using H13 steel as a blank comprises the following steps:

[0035] 1) Carry out general car processing on the blank, and leave a machining allowance of 3 mm according to the final product size, and then process the inner hole part of the CNC lathe, and leave a machining allowance of 1 mm for the hole size;

[0036] 2) Carry out preheating treatment on the blank processed by CNC lathe, and then carry out vacuum quenching and tempering to obtain the die part 1 with a hardness reaching HRC47~52 degrees;

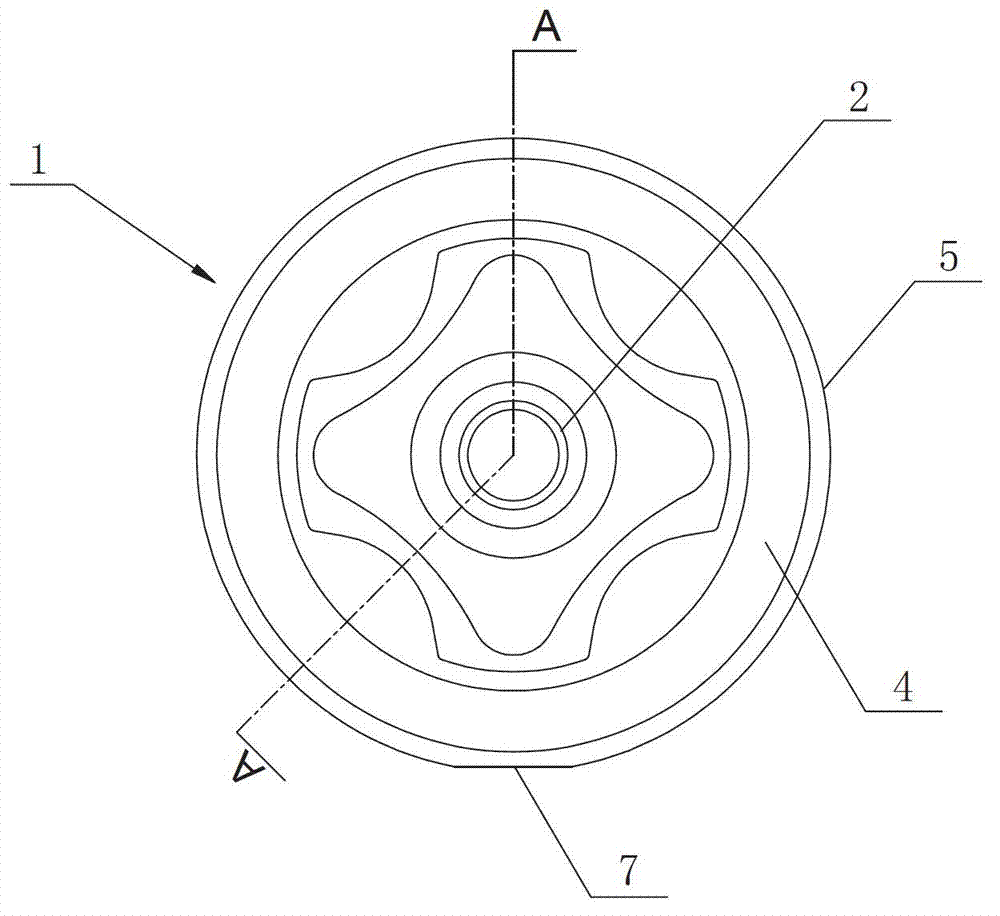

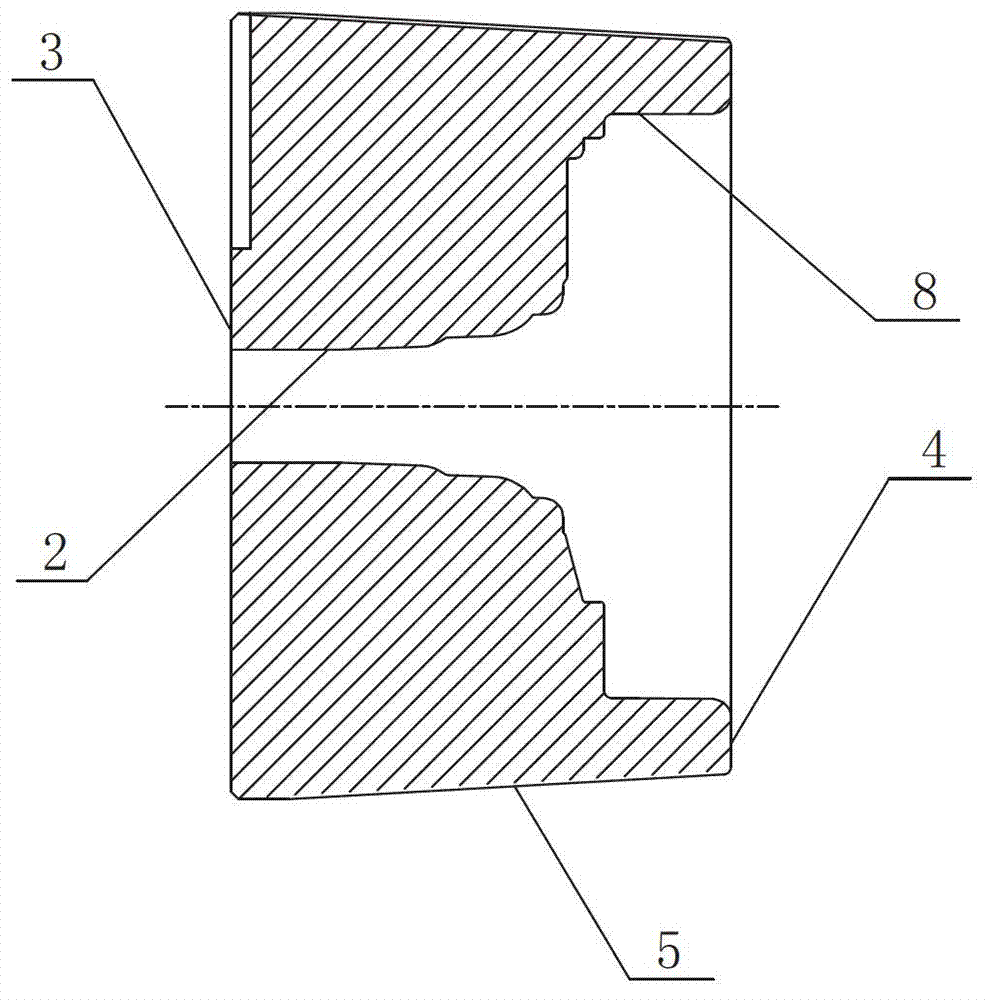

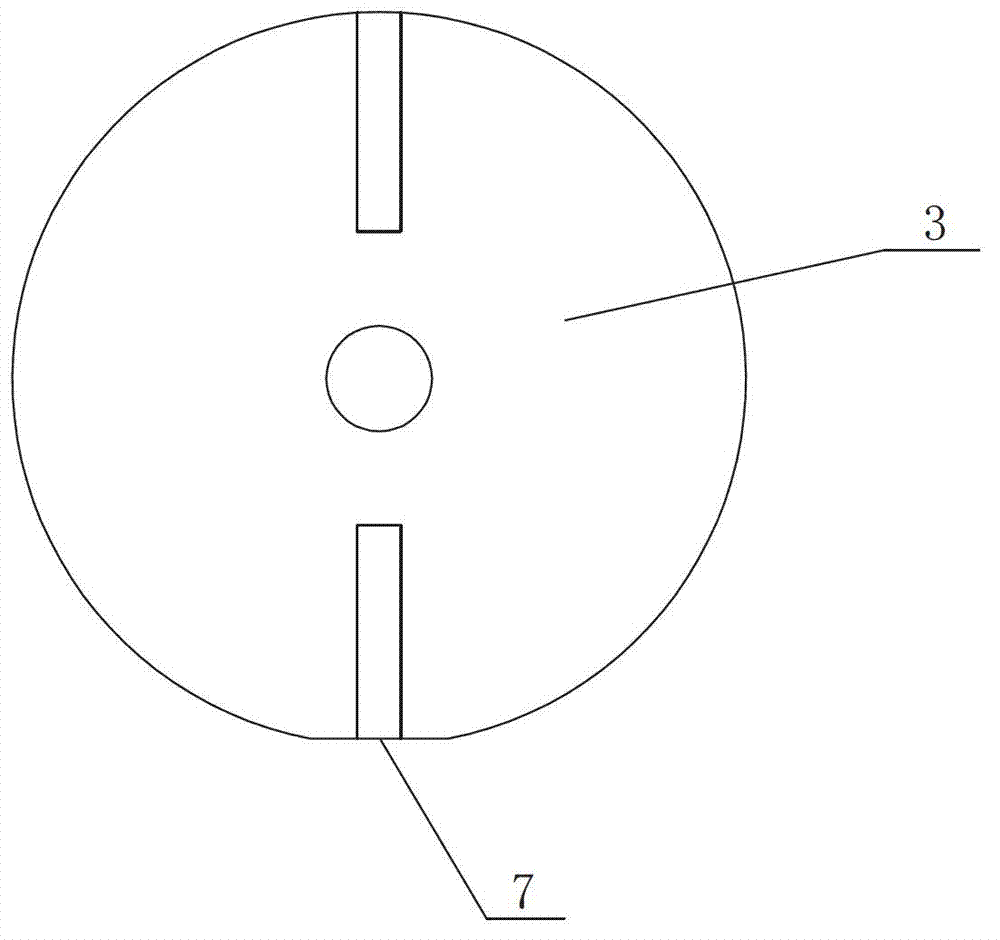

[0037] 3) Carry out CNC machining on the die part 1 again, process the bottom surface 3 of the conical frustum of the die part and leave a machining allowance of 0.3mm, then process and remove the allowance of the inner hole part 2 and the outer dimension of the die part 1, and then Polishing the bore portion 2;

[0038] 4) After polishing, take the top surface 4 of the truncated cone of the concave mold 1 as the reference pl...

Embodiment 2

[0049] The processing method of the four-station die using H13 steel as a blank comprises the following steps:

[0050] 1) Carry out general car processing on the blank, and leave a machining allowance of 3 mm according to the final product size, and then process the inner hole part of the CNC lathe, and leave a machining allowance of 1 mm for the hole size;

[0051] 2) Carry out preheating treatment on the blank processed by CNC lathe, and then carry out vacuum quenching and tempering to obtain the die part 1 with a hardness reaching HRC47~52 degrees;

[0052] 3) Carry out CNC machining on the die part 1 again, process the bottom surface of the conical frustum of the die part and leave a machining allowance of 0.4mm, and then process and remove the allowance of the inner hole part 2 and the outer dimension of the die part 1, and then process the The inner hole part 2 is polished;

[0053] 4) After polishing, take the top surface 4 of the truncated cone of the concave mold 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com