The Method and Casting Structure of Epoxy Resin Sealing Filler Used as Hull Support Pad

An epoxy resin and filler technology, which is applied in the field of marine shafting positioning pads, can solve problems such as water leakage and gasket falling off, and achieve the effects of avoiding water seepage, avoiding falling off, and facilitating promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

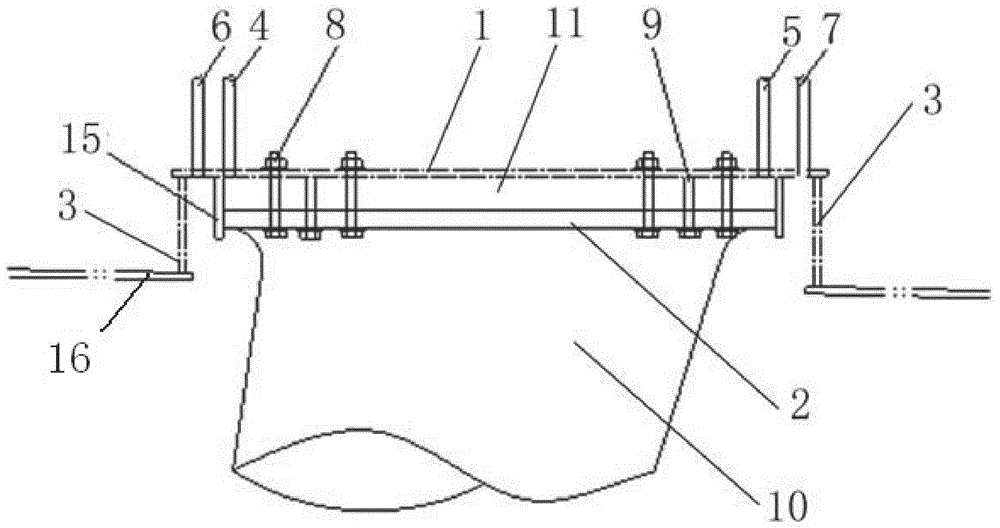

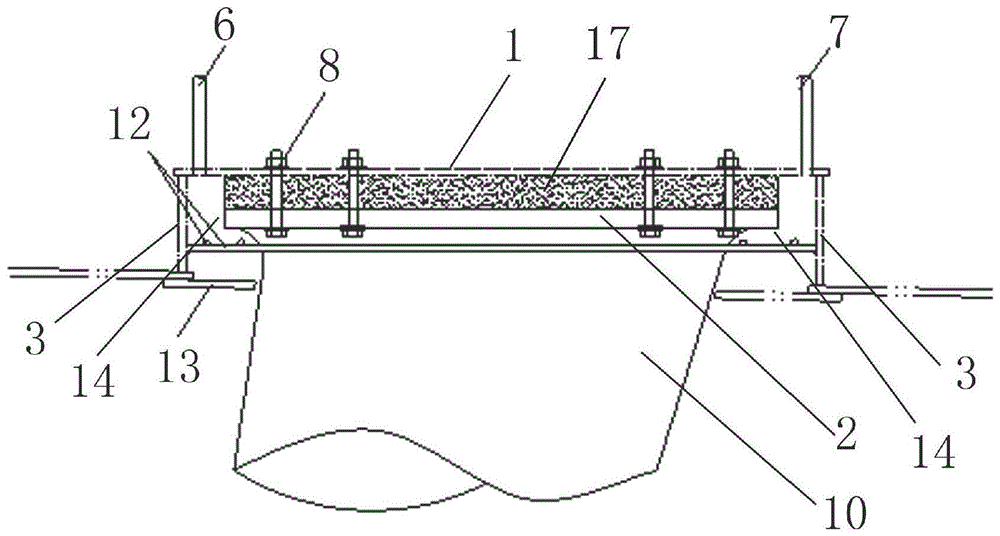

[0036] Such as figure 1 As shown, it is a schematic diagram of the structure of the mounting bracket. The top 1 of the bracket hole and the coaming plate 3 of the bracket hole are steel plates with the same material and thickness as the hull plate 16. They form a sealed box and are welded with the hull 16. Pack together to form a bracket hole for installing the bracket, so that the bracket installation part can be hidden in the hull to keep the linearity of the hull 16. The bracket includes a bracket top 2 and a bracket arm 10. The bracket is fixed in the bracket hole by positioning bolts 9 and fastening bolts 8. An injection port A4, an injection port B6, a vent port A5 and a ventilating port are set at the top 1 of the bracket hole. Port B7, after the whole bracket is adjusted and positioned according to the axis, remove the bracket. Remove the sundries and rust on the mounting surface of bracket hole top 1, bracket top 2 and bracket hole coaming plate 3, and then put the b...

Embodiment 2

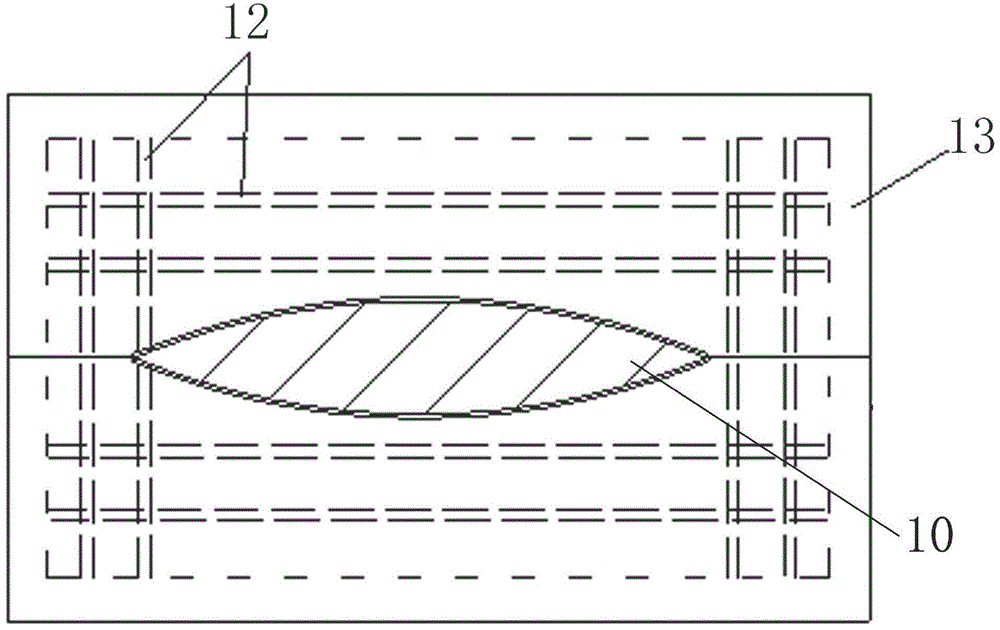

[0040] The difference from Example 1 is that the top 1 of the bracket hole and the surrounding plate 3 of the bracket hole are smaller than those in Example 1, and the 12 grid-like structural supports are welded by round steel, and the diameter is as large as Φ5mm, the distance between the grid-shaped structure support 12 and the bottom plate of the hull 16 is 12mm, the curing agent used is aromatic polyamine, and the rest of the working principles are the same as in Embodiment 1.

Embodiment 3

[0042] The difference from Example 1 is that the top 1 of the bracket hole and the surrounding plate 3 of the bracket hole are larger than those in Example 1, and the 12 grid-like structural supports are welded by round steel, and the diameter is as large as It is Φ10mm, and the distance between the lattice structure support 12 and the bottom plate of the hull 16 is 20mm. The curing agent used is an aromatic polyamine, and the remaining working principles are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com