Heat-conductive two-sided flexible copper clad laminate and manufacturing method thereof

A flexible copper clad laminate and double-sided technology, which is applied in the production field of the thermally conductive double-sided flexible copper clad laminate, can solve the problems of export and dissipation, low thermal conductivity, and large heat generation, so as to enhance thermal conductivity, improve thermal conductivity, reduce The effect of small thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

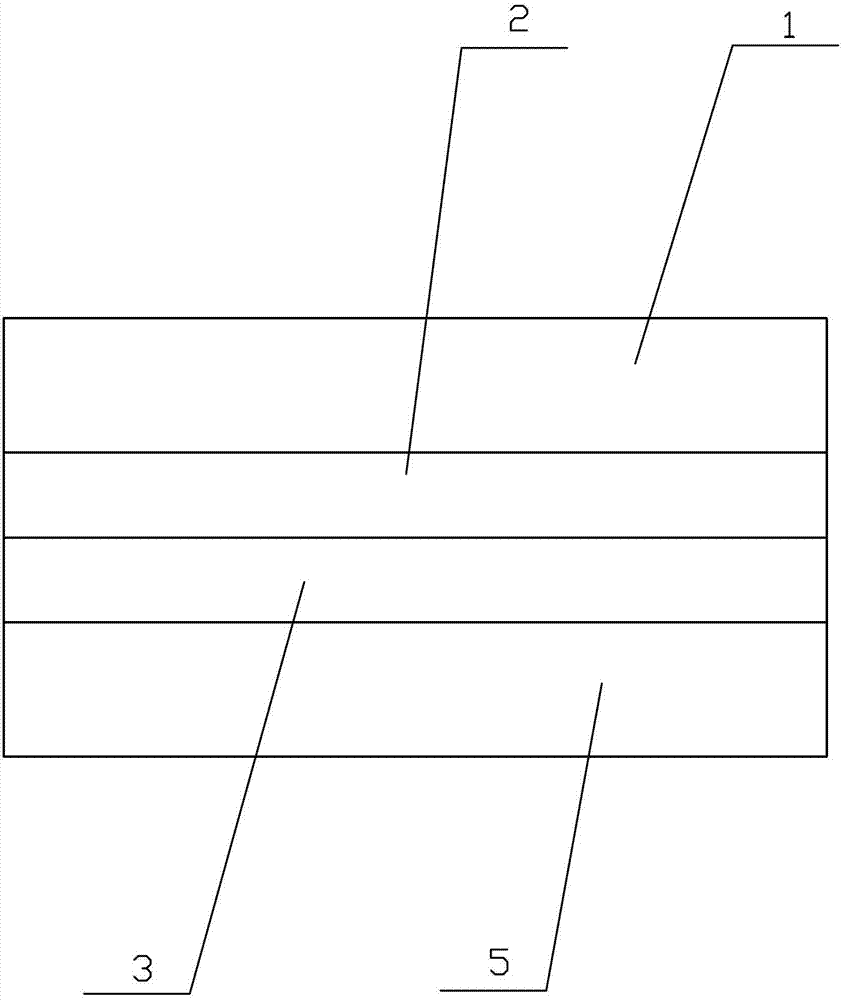

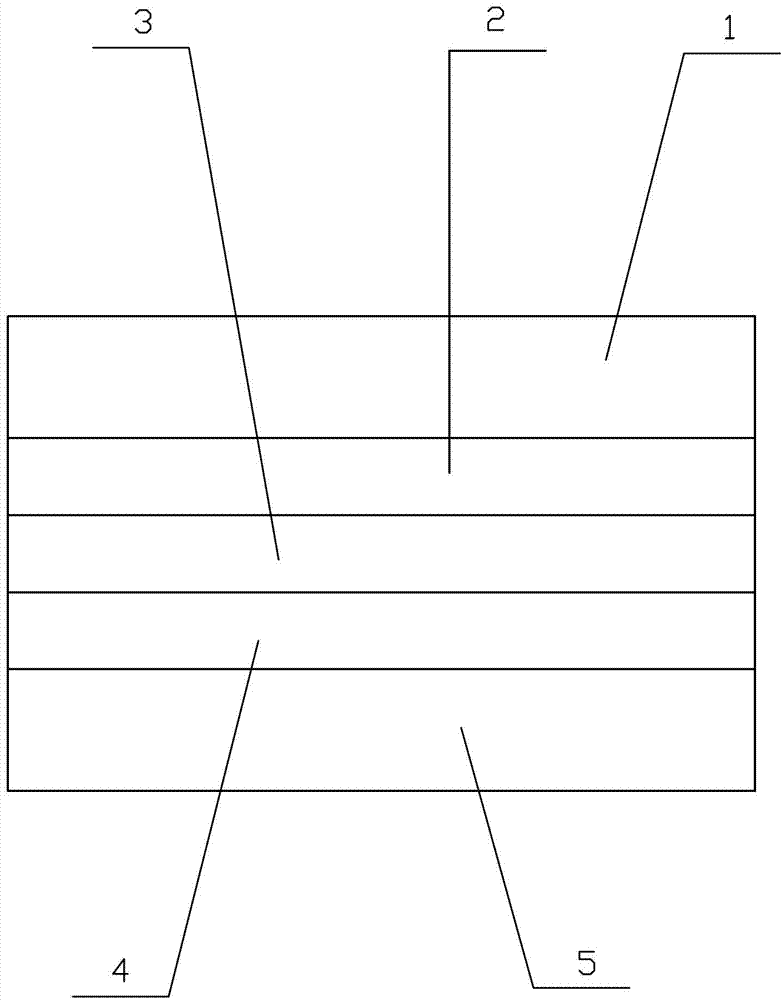

[0025] Such as figure 2 As shown, the second embodiment of the present invention is to add a second heat-conducting polyimide layer 4 between the heat-conducting adhesive layer 3 and the second copper foil 5, that is, press the other side of the heat-conducting adhesive layer 3 The second thermally conductive single-sided copper-clad laminate is coated with the second copper foil 5 and the second thermally conductive polyimide layer 4 coated thereon to form a second thermally conductive single-sided copper-clad laminate.

[0026] The first copper foil 1 is one of electrolytic copper foil and rolled copper foil, the second copper foil 5 is one of electrolytic copper foil and rolled copper foil, the first copper foil 1 and the second copper foil 5 The same, the thickness is 3~35um.

[0027] The first thermally conductive polyimide layer and the second thermally conductive polyimide layer are also the same, with a thickness of 3~25um, containing 1%~10% solid content of thermall...

Embodiment 1

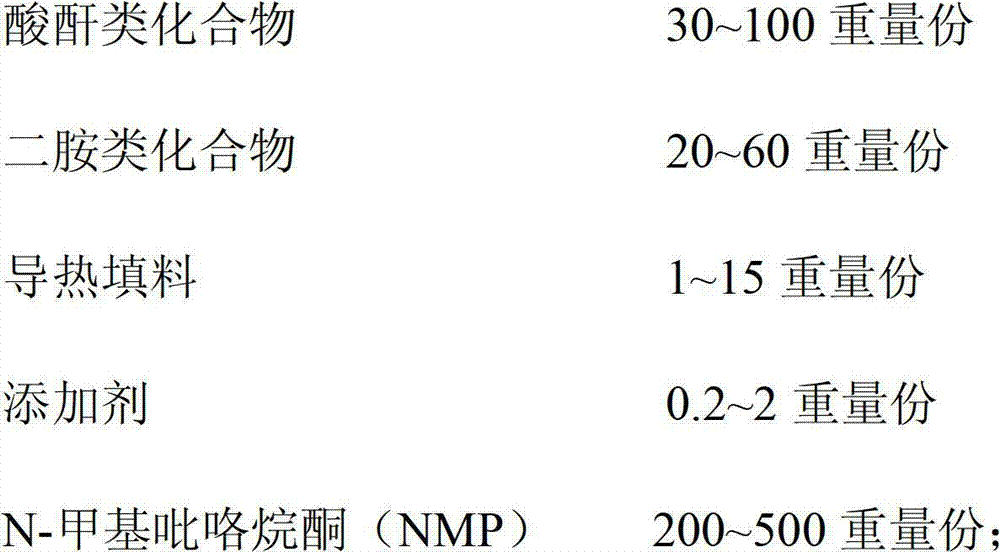

[0049] Thermally conductive polyamic acid composition:

[0050] Dissolve 0.5 parts by weight of coupling agent, 0.5 parts by weight of dispersant, and 15 parts by weight of aluminum nitride in 300 parts by weight of NMP solvent, and add diaminodiphenyl ether (ODA for short) into the solution, so that the equivalent ratio of ODA to ODA is 0.997 Pyromellitic dianhydride (PMDA) was also added and dissolved, the total amount of ODA and PMDA accounted for 86 parts by weight, stirred at 20°C for 48 hours, and polymerized to obtain a polyamic acid composition;

[0051] Preparation of the first thermally conductive single-sided flexible copper clad laminate

[0052] The above-mentioned polyamic acid composition was coated on a 18um rolled copper foil with a coating thickness of 8um, baked at 180°C for 3 minutes, and then baked at 350°C for 10 minutes to obtain the first thermally conductive single-sided flexible copper clad laminate, for later use.

[0053] Thermally conductive adhe...

Embodiment 2

[0058] Thermally conductive polyamic acid composition:

[0059] Dissolve 1.0 parts by weight of coupling agent and 15 parts by weight of alumina in 300 parts by weight of NMP solvent, add diaminodiphenyl ether (ODA for short) to dissolve, and dissolve pyromellitic dianhydride with an equivalent ratio of 0.997 to ODA (PMDA) was also added and dissolved, the total amount of ODA and PMDA accounted for 86 parts by weight, stirred at 20°C for 48 hours, and polymerized to obtain a polyamic acid composition;

[0060] Preparation of the first thermally conductive single-sided flexible copper clad laminate

[0061] The above-mentioned polyamic acid composition was coated on a 18um rolled copper foil with a coating thickness of 10um, baked at 180°C for 3 minutes, and then baked at 350°C for 10 minutes to obtain the first thermally conductive single-sided flexible copper clad laminate, for later use.

[0062] Thermally conductive adhesive using modified acrylic composition

[0063] 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com