Standard component storage device and photovoltaic module testing system with same

A standard component and storage device technology, which is applied in the field of standard component storage device and photovoltaic component testing system with the device, can solve the problems of standard component no longer stable, standard component physical damage, electrical parameter attenuation, etc., to prevent attenuation , prolong the service life, and reduce the cost of component testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

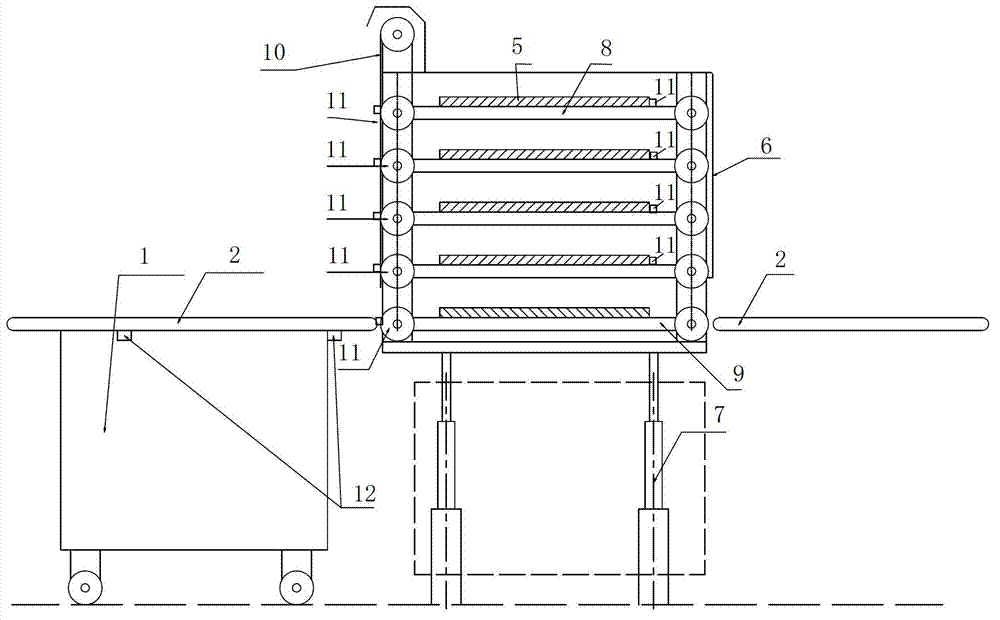

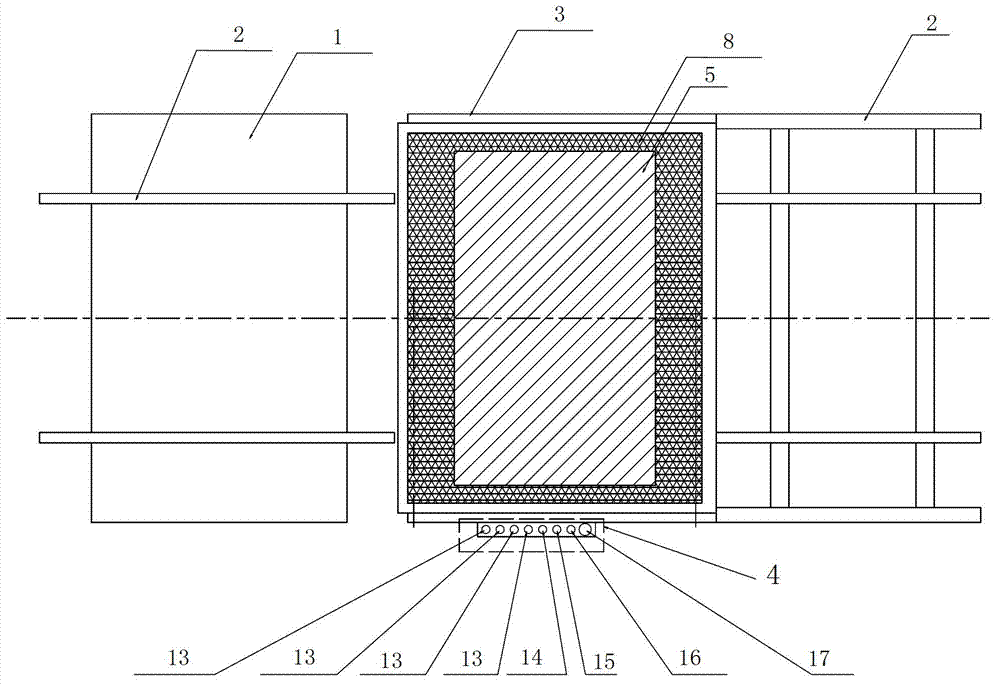

[0017] A standard component storage device, comprising a storage cabinet 6 and a lifting device 7, in the storage cabinet 6 there are a plurality of standard component transfer devices 8 arranged in layers along the up and down direction as a standard component storage platform, in the cabinet body of the storage cabinet 6 One side has a standard assembly access opening for the standard assembly 5 to enter and exit the cabinet, and a closing device for closing the standard assembly access opening after the standard assembly enters and exits the cabinet. The storage cabinet 6 is installed on the lifting device 7 . The storage cabinet 6 is also provided with a layer of component-to-be-test transmission device 9 for transmitting components to be tested. The component transmission device 9 to be tested and other standard component transmission devices 8 are arranged in layers along the up and down direction. There is an opening for the component to be tested to enter and exit the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com