Method and system for modularized combined treatment of high-difficulty organic waste water

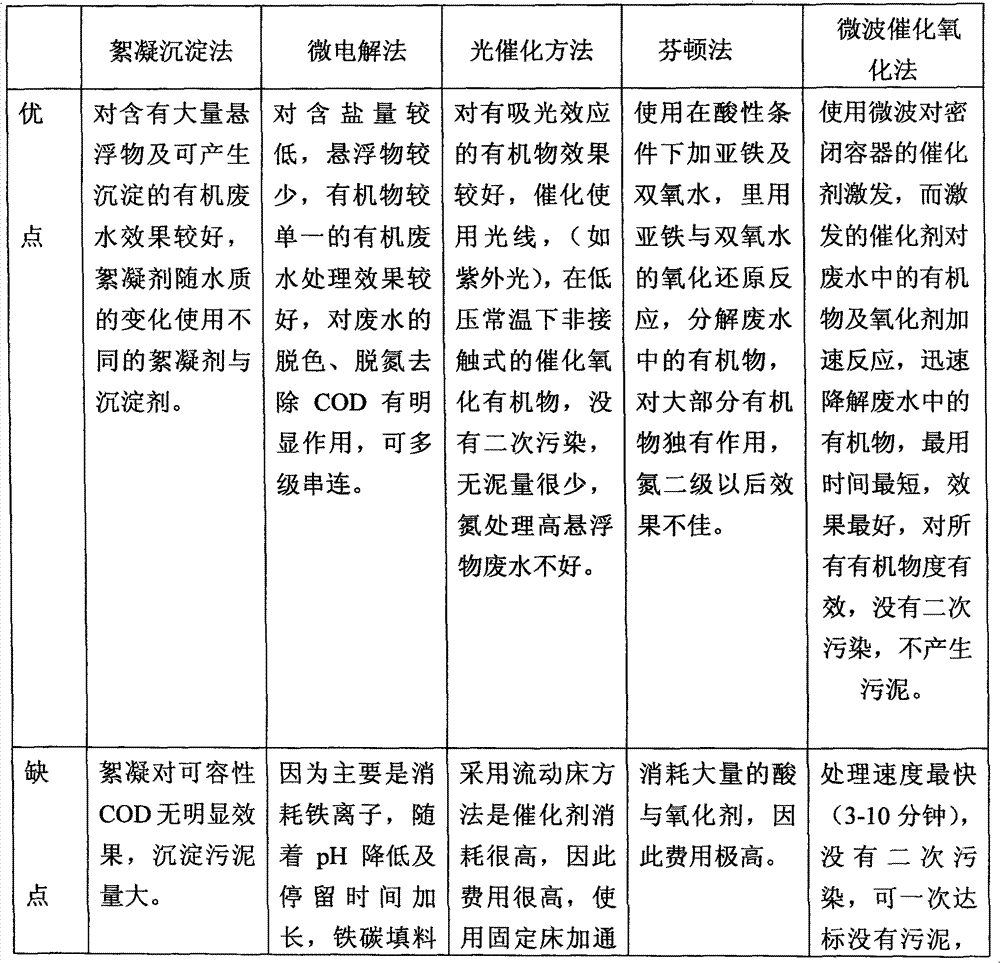

An organic wastewater, combined technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of high consumption of treatment equipment and materials, high operating costs, inability to run continuously and stably, and poor treatment effect. It can achieve the effect of high applicability, low operating cost and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

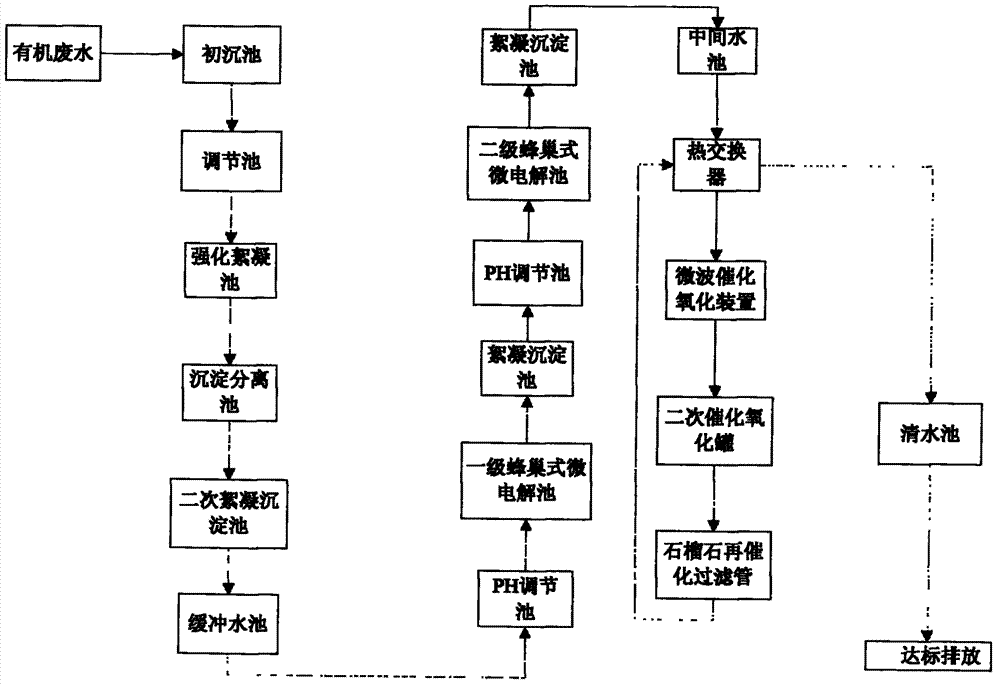

[0026] by figure 1 As shown, a modular combined treatment system for the treatment of difficult organic wastewater includes: primary sedimentation tank, adjustment tank, enhanced flocculation tank, sedimentation separation tank, secondary flocculation sedimentation tank, buffer tank, pH adjustment tank, one Grade honeycomb micro electrolytic cell, flocculation sedimentation tank, secondary honeycomb micro electrolytic cell, intermediate pool, heat exchanger, microwave catalytic oxidation device, secondary catalytic oxidation tank, garnet re-oxidation filter tube.

[0027] The first-level honeycomb micro electrolytic cell is a honeycomb iron-carbon micro electrolytic cell. The structure of the iron-carbon micro electrolytic cell is a honeycomb grid filled with activated carbon particles and cast iron pins. The weight ratio of the two is 1:3, and the thickness of each grid plate is 3-10cm, layer by layer until 2 / 3 of the height of the electrolytic cell, separated by glass cloth betw...

Embodiment 2

[0031] A method for treating organic wastewater with high salt, high ammonia nitrogen, and high COD by using the above-mentioned system. The process is as follows: the wastewater is upgraded to an enhanced flocculation tank after passing through the primary sedimentation tank and the adjustment tank for flocculation, and the flocculated wastewater is discharged into the sediment Separation tank, after sedimentation, drain the supernatant into the secondary flocculation sedimentation tank, add bleaching powder and stir, after sedimentation and separation, drain the supernatant to the buffer pool, and then pump the buffer pool wastewater into the pH adjustment pool to adjust the wastewater After pH, pump into the first-level honeycomb micro-electrolysis cell, after aeration for 1-2h, overflow into the flocculation sedimentation tank, add saturated lime water for flocculation and sedimentation, and add 0.5‰-3‰ polyacrylamide, the wastewater produces iron blue to iron red Flocculent...

Embodiment 3

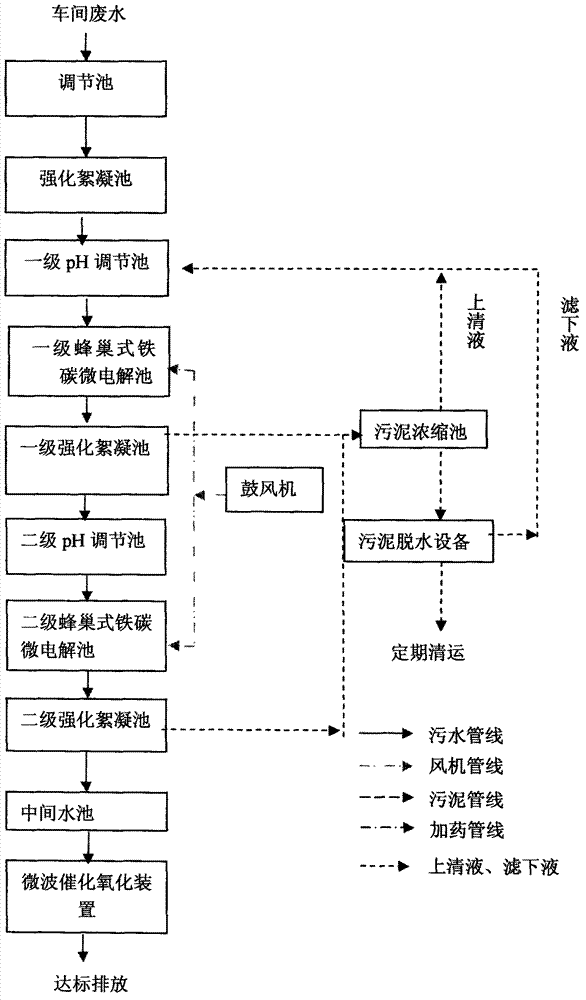

[0040] As shown in Figure 3, it is the process of the nitrile wastewater treatment method. The pollutants in the wastewater are complex and the content of organic matter is relatively high. The nitrile substances contained in the wastewater can cause water toxicity and potential "three-induced" toxicity. The measured wastewater influent water quality indicators are as follows:

[0041] Raw water quality: COD≤15000mg / L; acrylonitrile: 2000mg / L, ammonia nitrogen≤67.2mg / L; PH: 8; TDS≤36000ppm; SS≤50000ppm; COD Cr ≤500mg / L; BOD 5 ≤250mg / L; SS≤300mg / L; acrylonitrile≤5. The process flow is as follows:

[0042] The wastewater from the production workshop passes through the primary sedimentation tank to remove the large debris and the particulate solids in the sedimentation water, and then enters the adjustment tank to adjust the water volume and balance the water quality, and then enters the enhanced flocculation tank. In the enhanced flocculation, 90% fly ash plus 10 % Powder activated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com