Automatic reversing workbench for cutting glass

An automatic turning and worktable technology, applied in manufacturing tools, glass manufacturing equipment, glass cutting devices, etc., can solve problems such as personal injury, glass breakage, glass damage, etc., to reduce labor intensity, eliminate potential safety hazards, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

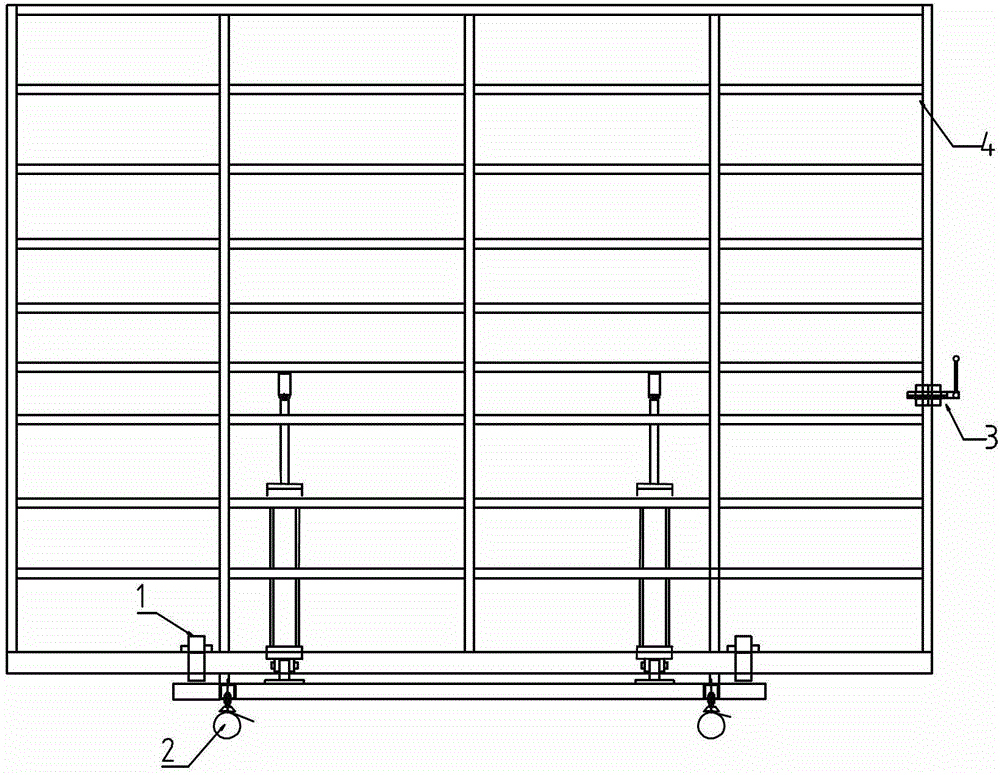

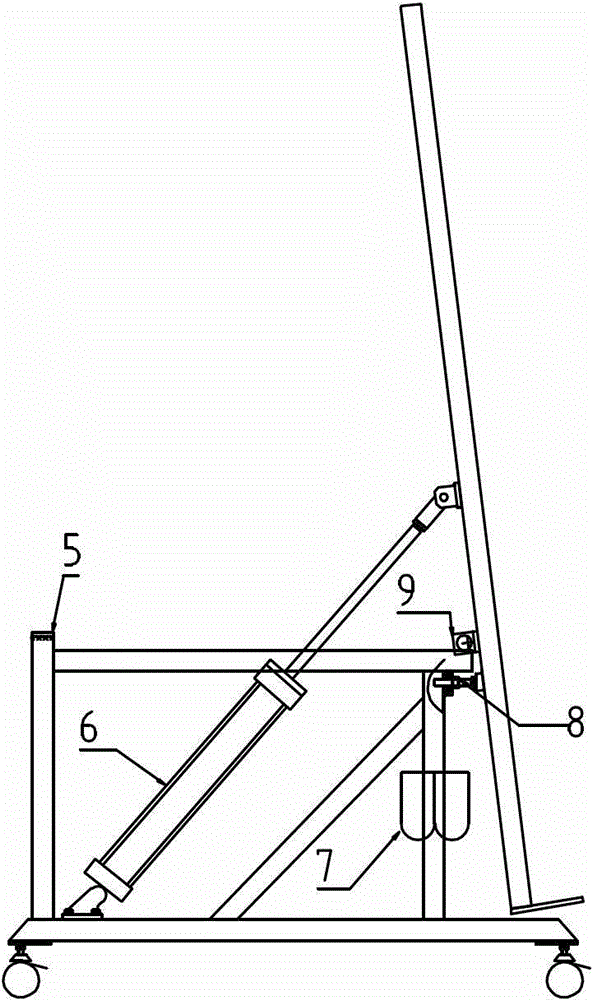

[0011] Such as figure 1 and figure 2 As shown, the automatic turning table for drawing glass includes a bracket 1, four brake universal wheels 2 installed under the bracket 1, a turning platform 4, a shock absorbing device 5, two cylinders 6, limit bolts 8 and turning shafts 9; The support 1 in this embodiment is a rectangular frame. The brake universal wheel 2 can make the workbench be transposed and fixed arbitrarily, so as to realize the "zero-distance" handling of glass. The overturning platform 4 is installed on one side of the top surface of the support 1 by the overturning shaft 9, and is positioned by a limit mechanism installed on the overturning platform 4; the limit mechanism includes a limit bolt 8 installed below the overturning platform 4, The position corresponding to the stop bolt 8 has a screw hole, and the turning platform 4 is positioned by the stop bolt 8 installed on the turning platform 4 and the screw nut on the support; the stop bolt 8 controls the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com