Process for producing aluminum alloy conductor

A technology of aluminum alloy wire and production process, which is applied in the field of metal plastic processing, can solve the problems of increased process and production cost, oxidation of the surface of the billet, high production cost, etc., and achieves the effects of excellent surface quality, low production cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

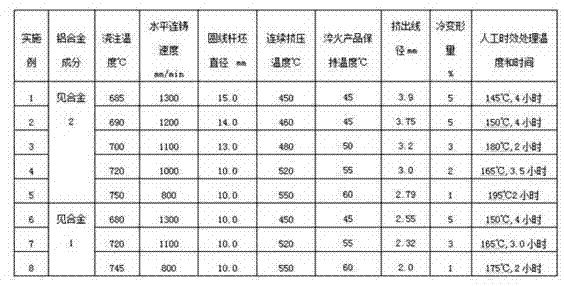

[0016] The embodiment uses 99.7% aluminum ingots, magnesium ingots, and Al-Si, Al-Fe master alloys, according to the chemical composition of aluminum alloy wires, after melting, the chemical composition of the melt samples is analyzed by direct spectral reading method. The actual measured composition is shown in Table 1, where Alloy 1 corresponds to LHA1 and Alloy 2 corresponds to LHA2. A horizontal continuous casting machine with a crystallizer is used to cast a round wire billet with a certain diameter. After the round wire billet is cleaned, it is extruded on an LJ300 aluminum continuous extrusion machine to form a product with a certain diameter. Die mouth products are directly quenched in water online and then coiled by online small cold deformation stretching and winding, and then artificial aging treatment is carried out in a 90KW box-type resistance furnace. The aluminum alloy composition, pouring temperature, horizontal continuous casting speed, continuous Extrusion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com