Electrolyte plasma polishing machine for mass production

A plasma and polishing machine technology, which is applied in the field of ion polishing machines, can solve the problems of unsuitable enterprises for mass production and low production efficiency of polishing equipment, and achieve the effect of increasing the polishing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

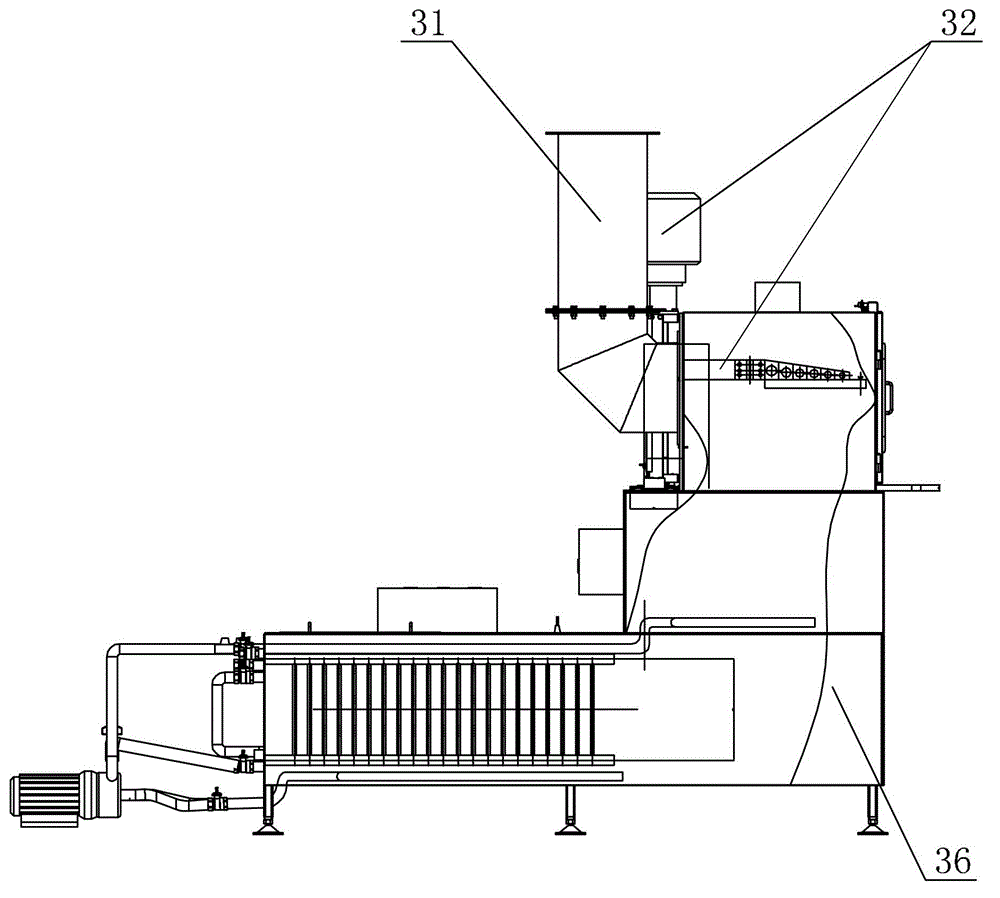

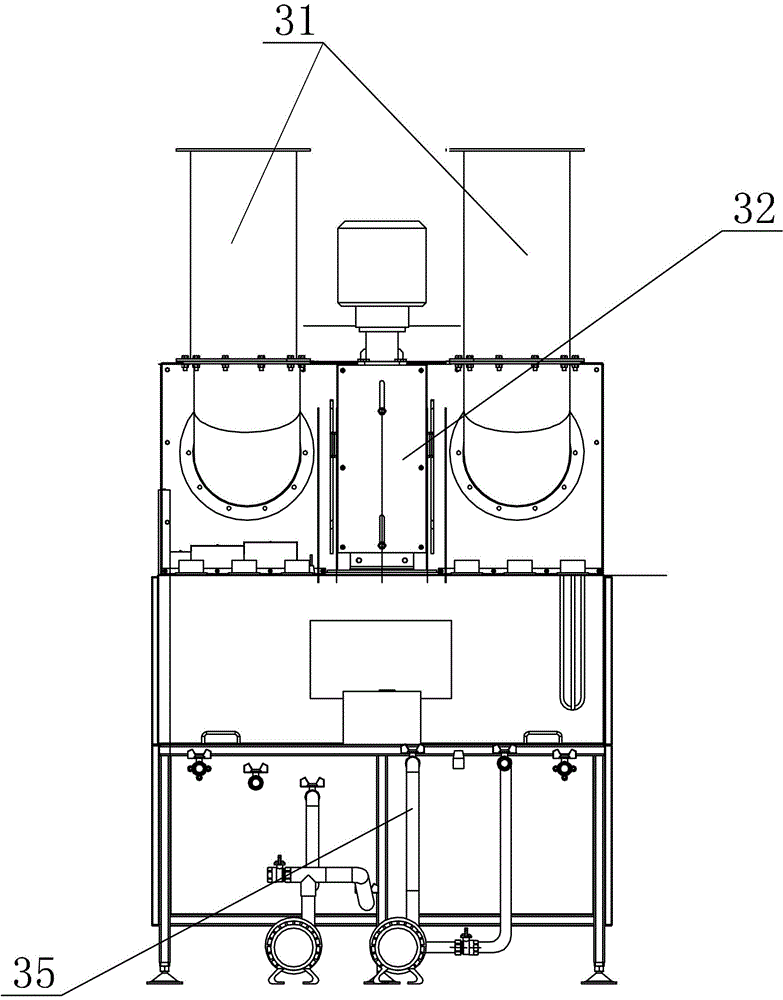

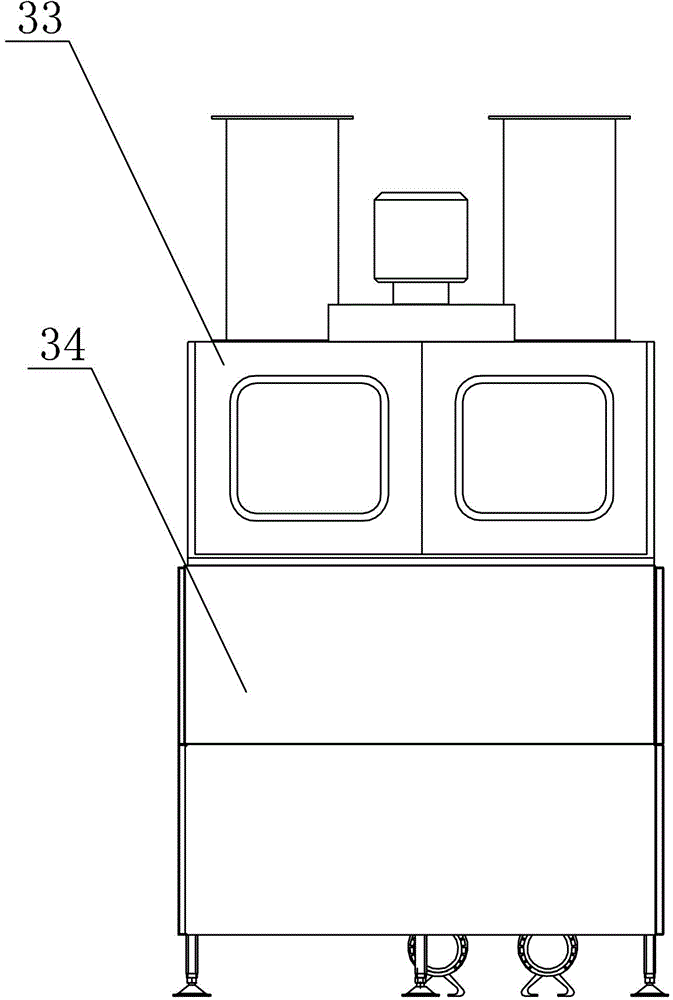

[0010] Specific implementation mode one: as Figure 1-10 As shown, the electrolyte plasma polishing machine for mass production in this embodiment includes a hanger and a lifting device 32, a working upper box 33, a working box 34, a liquid storage tank 36, a circulating stirring device 35 and two exhaust recovery devices 31. Case 34 is installed on the upper end face of liquid storage tank 36, and circulating stirring device 35 is installed on the sidewall of liquid storage tank 36 and both communicate with each other, and upper case 33 of work is positioned at the upper end face of working case 34, and two exhaust Recovering device 31 is relatively installed on the side wall of upper case 33 of work, and lifting device 32 is positioned between two exhaust air recovery devices 31 and is installed on the described side wall of upper case 33 of work; Each exhaust wind recovery device 31 It includes an exhaust air recovery pipeline 31-1, a catcher 31-2, two baffles 31-4 and a pl...

specific Embodiment approach 2

[0015] Specific implementation mode two: as figure 1 As shown, in this embodiment, a plurality of through holes 31-5 are evenly distributed along the circumferential direction. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: as figure 1 As shown, the diameter of the plastic ball 31-3 in this embodiment is 10 mm. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0017] working principle:

[0018] Connect the workpiece to the anode with a wire, start the servo motor 1, the output shaft of the servo motor 1 drives the screw rod 21 to rotate, the screw rod 21 rotates to drive the screw nut sleeve 24 to move downward, and at the same time drives the conductive hanger 29 and the workpiece to be polished to slowly sneak into the In the polishing liquid, the polishing liquid is evaporated due to the instantaneous short circuit of the system to form a gas layer surrounding the workpiece, which completely separates the workpiece from the polishing liquid; the above gas layer enters the plasma state under the action of the voltage, and the workpiece to be polished is polished; During the polishing process, the polishing liquid is eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com