Method and apparatus for polishing large-scale diamond membrane

A diamond film and large-area technology, applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve the problem of high polishing roughness and achieve large polishing area, high polishing precision, and high polishing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

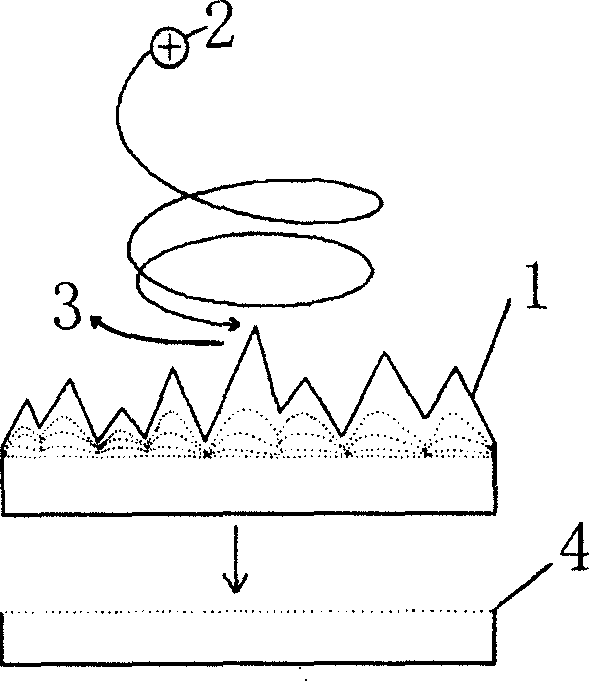

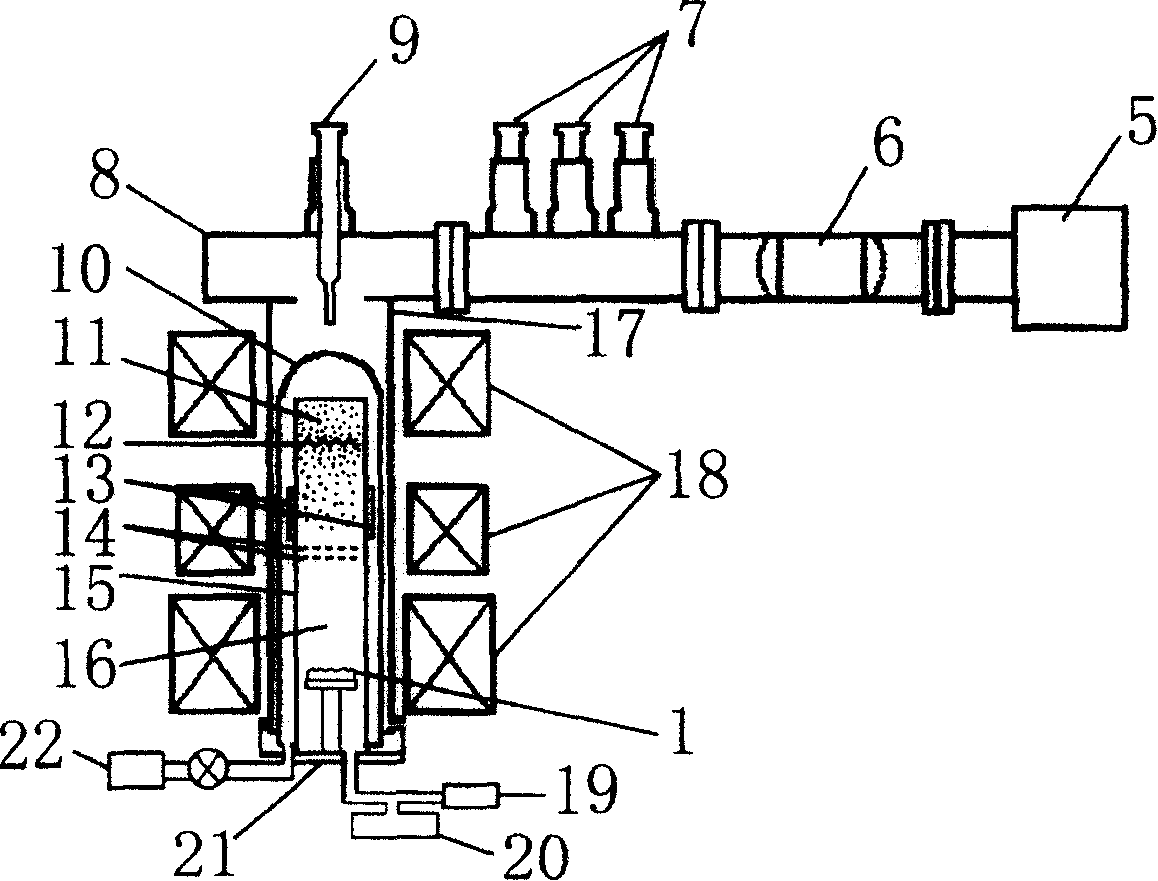

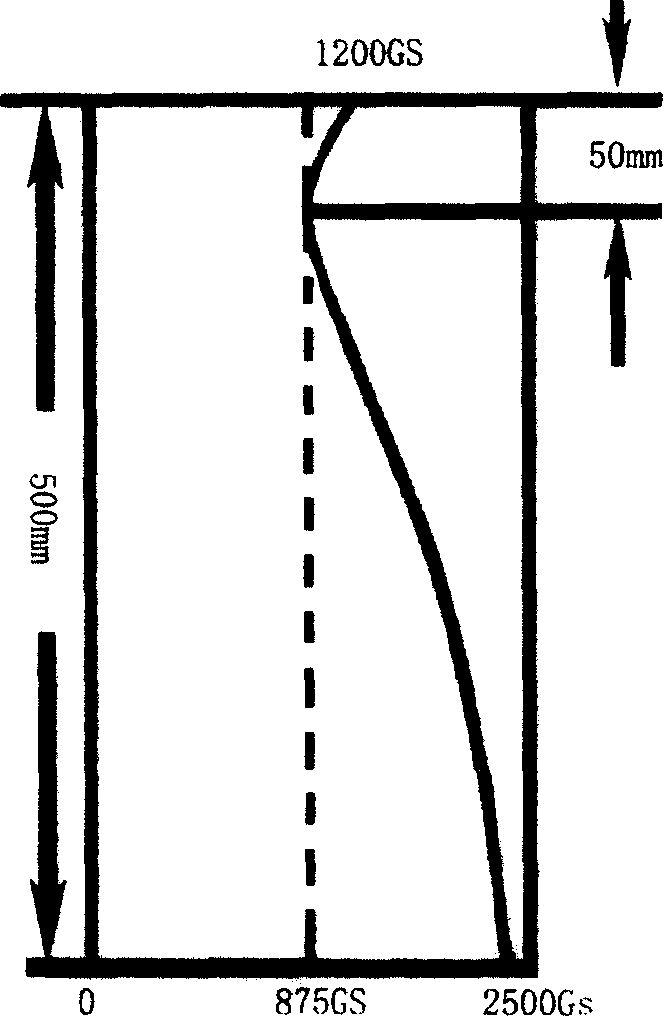

[0024] The present invention is a method for polishing a large-area diamond film by using plasma. The method is as follows: firstly, using microwave excitation to generate electron cyclotron resonance plasma, and then using ion cyclotron resonance heating to couple high-frequency power to ion components in the plasma , raise the kinetic temperature of the ions to 10-40eV, and then use the extraction electrode and the gradient magnetic field to control the movement of the ions in the plasma, so that the ions move down to the surface of the diamond film and selectively interact with the diamond film surface to be removed. The carbon atoms undergo an etching reaction to generate volatile gases, thereby completing the polishing of the diamond film.

[0025] This method comprises generation of plasma, ion heating in plasma, ion motion control and ion etching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com