Full-thread glass fiber composite hollow grouting anchor rod

A technology of grouting bolts and glass fiber, which is applied in the installation of bolts, sheet pile walls, mining equipment, etc., can solve the problems of poor coping ability of ordinary mortar bolts, difficult to control the fullness of mortar, and providing supporting plate force, etc. To achieve the effect of alleviating the collapse and roofing accidents and other engineering diseases, alleviating the collapse and roofing accidents or other diseases, and inhibiting loosening and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

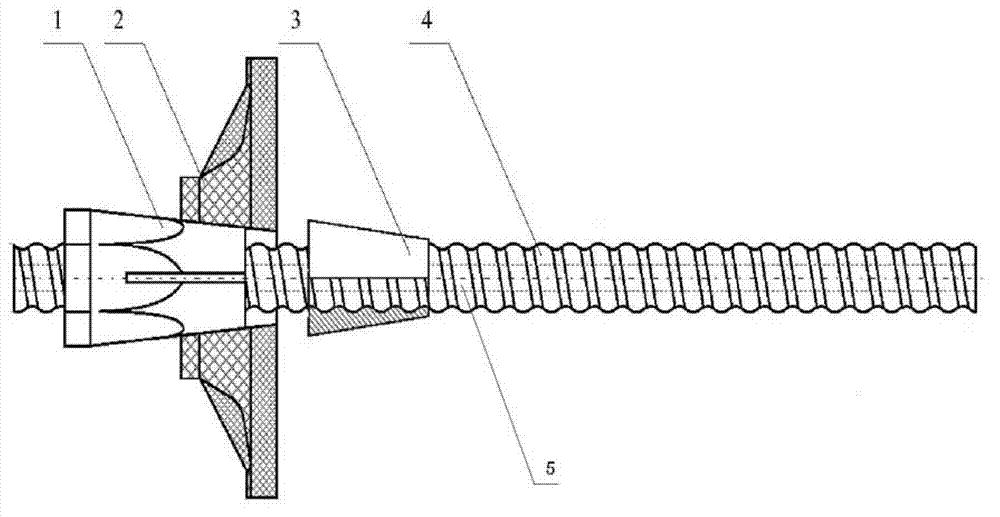

[0016] Referring to the accompanying drawings, the full-thread glass fiber composite hollow grouting anchor includes a hollow grouting anchor 4 extending into the rock and soil anchor hole, and a grouting hole 5 is opened in the hollow grouting anchor 4, and the hollow grouting The outer wall of the anchor rod 4 is a full thread section, and the hollow grouting anchor rod 4 is respectively screwed with a grout stopper 3 and a lock nut 1 corresponding to the anchor hole. The front part of the lock nut 1 has a cone section, and the lock nut There is a screwing section at the rear, and a tray 2 is matched on the cone section. The front end of the tray 2 is pressed on the rear end surface of the stopper 3. An anchor head is provided on the back side of the tray 3, and the anchor head is set on the lock nut 1. On the cone segment and against the rear end face of the tray, the material of the anchor head and the tray is glass fiber reinforced plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com