Control system for turbine

An instrument control system, steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as inability to achieve inspection, troubleshooting, lack of online debugging function and dual-machine test interlock function, etc., to avoid The effect of equipment damage accidents, reducing personnel input, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

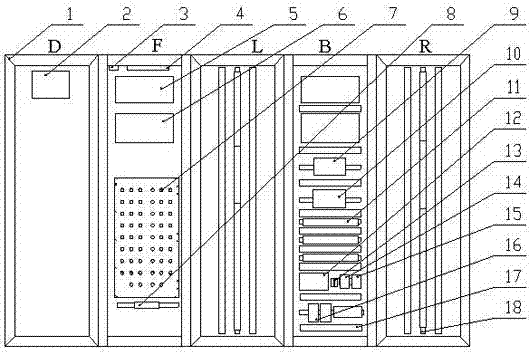

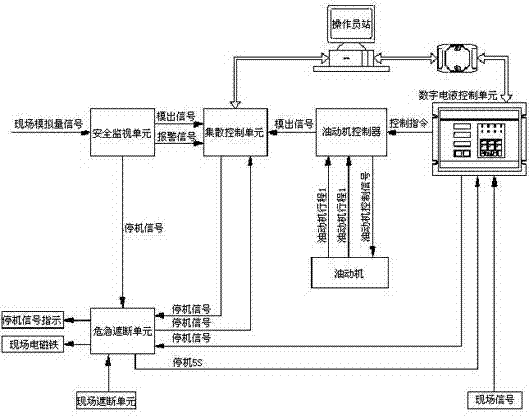

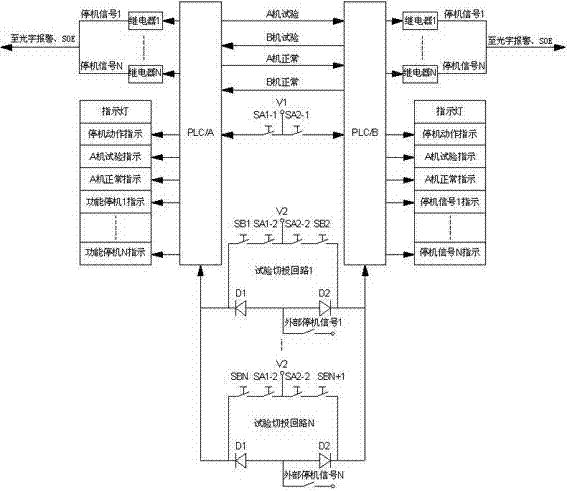

[0024] Such as Figure 1~3 As shown, the steam turbine instrument control system of the present invention includes:

[0025] The safety monitoring unit 5 monitors the operation of the steam turbine generator set, measures the on-site analog signal and converts it into an electrical signal, and completes the collection, monitoring, and alarm of the steam turbine set operating parameters. The parameter acquisition part of the safety monitoring unit 5 is used to receive on-site sensor signals, such as steam turbine speed signals, vibration signals, axial displacement signals, and the like. After receiving the above-mentioned signals, the sampling loop inside the safety monitoring unit 5 processes, analyzes and calculates the signals, and the display module of the safety monitoring unit 5 displays the current measurement value and alarm and shutdown status in real time. At the same time, the safety monitoring unit 5 outputs a corresponding analog signal to the distributed control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com