An open seawater hydraulic pollution control system for deep sea operation equipment

A pollution control and equipment technology, which is applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of weak pollution control ability, difficulty in meeting filtration requirements, and inability to feed back filter pollution in real time, etc. , to achieve the effect of restoring filtration ability and strong pollution control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

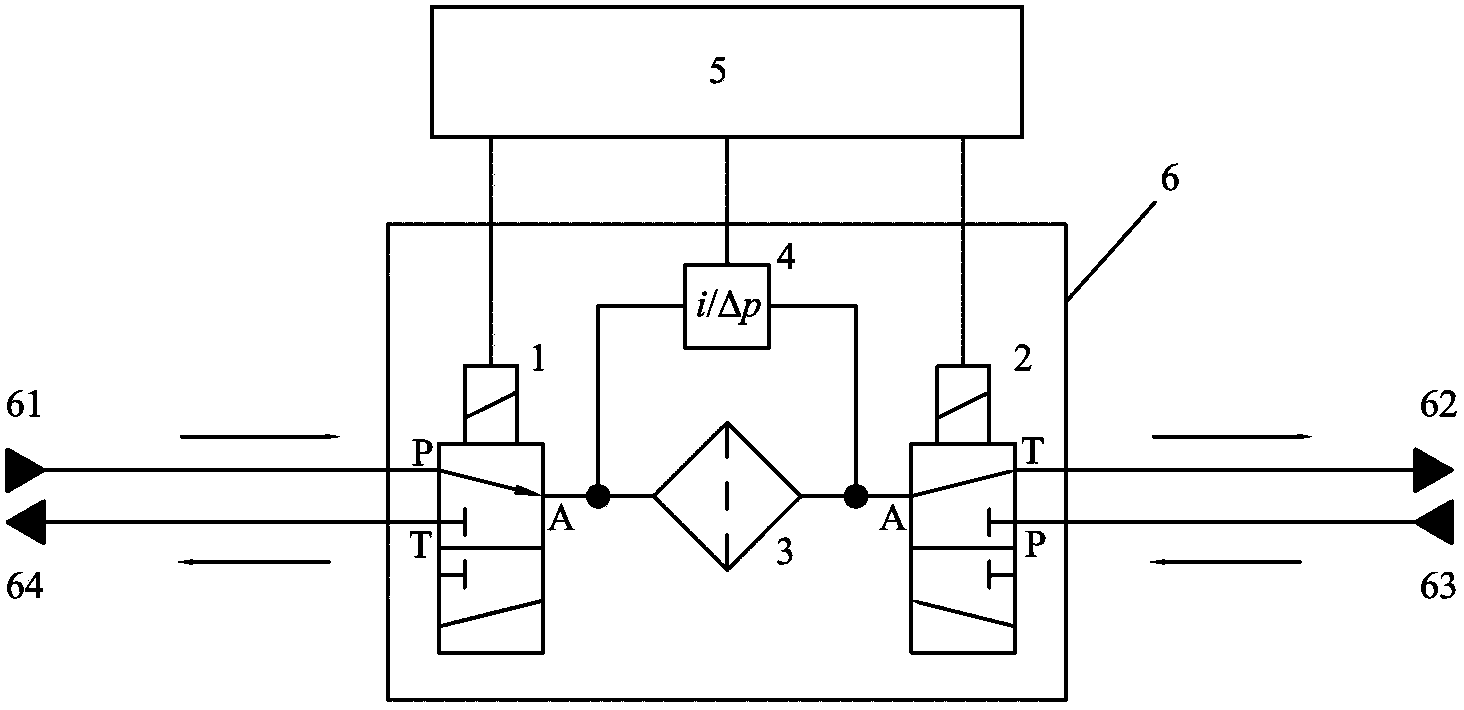

[0019] refer to figure 1 , The basic unit branch of the backwash filtration stage of the multi-stage redundant backwash open seawater hydraulic pollution control system includes: backwash filter 3, pressure difference sensor 4, water inlet three-way electric control valve 1, water outlet three-way electric control Valve 2, controller 5, pre-filtered water inlet 61, filtered water outlet 62, flushing water inlet 63, flushing water outlet 64; the P port, T port and A port of the water inlet three-way electric control valve 1 are respectively connected to the pre-filtered water The inlet 61, the flushing water outlet 64 are connected to the filter inlet of the backwash filter 3, and the P port, T port and A port of the outlet three-way electric control valve 2 are respectively connected to the flushing water inlet 63, the filtered water outlet 62 and the backwash filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com