Method for detecting and judging overheating fault of bus joint of gas insulation switch device

A technology for gas insulated switches and busbar joints, which is applied to the setting of switchgear, switchgear, and electrical measurement. It can solve the problems of hidden dangers, the inability of infrared thermal imaging cameras to realize online detection, and the lack of fault judgment criteria, etc., to achieve elimination and detection. The effect of the result, easy programming, good safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

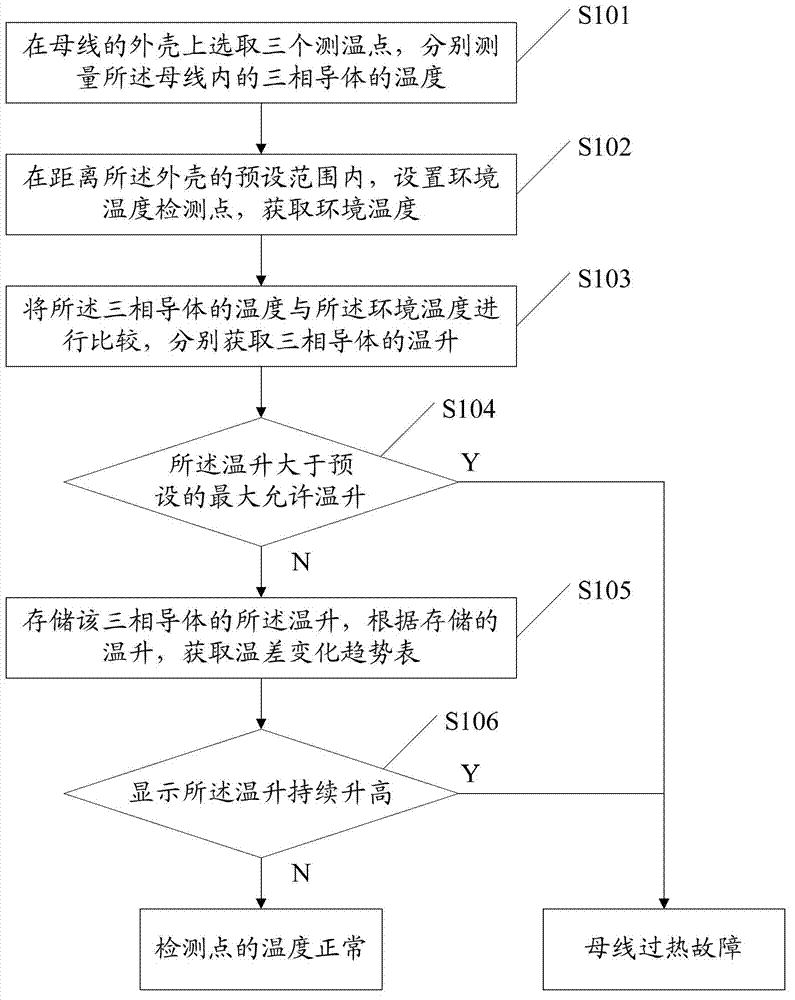

[0024] figure 2 It is a flow chart of the first embodiment of the method for detecting and judging overheating faults of bus joints of gas insulated switchgear according to the present invention, including:

[0025] S101: Select three temperature measuring points on the outer shell of the bus, and respectively measure the temperature of the three-phase conductors in the bus;

[0026] S102: Set an ambient temperature detection point within a preset range from the housing to acquire the ambient temperature;

[0027] S103: Comparing the temperature of the three-phase conductors with the ambient temperature, respectively obtaining the temperature rise of the three-phase conductors;

[0028] S104: When the temperature rise is greater than the preset maximum allowable temperature rise, determine the bus overheat fault; otherwise,

[0029] S105: Store the temperature rise of the three-phase conductor, and obtain a temperature difference change trend table according to the stored t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com