Nondestructive inspection method for roll neck of support roll

A non-destructive flaw detection and support roller technology, applied in the direction of material magnetic variables, etc., can solve the problems of inability to assess the degree of crack damage, poor detection sensitivity, inability to accurately locate crack positions and crack depths, and achieve accurate measurement and hazard assessment, safe use. significant, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

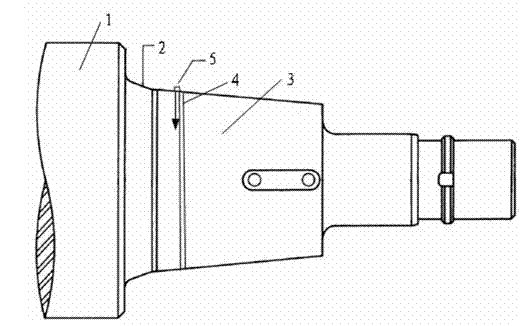

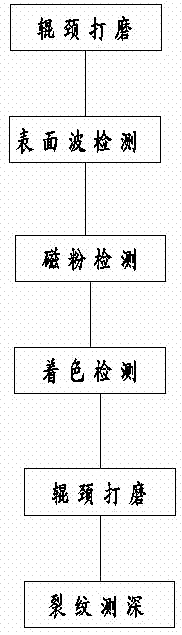

[0040] see figure 1 , figure 2 , a backup roll roll neck non-destructive testing method, comprising the steps of:

[0041] (1) Grinding of the roll neck: perform preliminary grinding on the roll neck, remove the rust on the surface of the roll neck, and use sandpaper to polish, so that the surface finish of the R part of the roll neck reaches Ra0.2;

[0042] (2) Surface wave detection: Use a small-sized chip surface wave probe to detect the roll neck position, and if there is an abnormal echo area in the surface wave scan, mark the abnormal echo area;

[0043] (3) Magnetic particle inspection: carry out wet continuous magnetic particle inspection on the abnormal echo area, using DC yoke and black

[0044] Magnetic suspension fluid, which magnetizes the area to be detected in both axial and circumferential directions, and marks th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com