Automation control system for plate forming production line

An automatic control and production line technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems affecting the economic benefits of production enterprises, low production efficiency, and high failure rate, saving labor costs, Improve production efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments, and the purpose is only to better understand the content of the present invention. Therefore, the examples cited do not limit the protection scope of the present invention.

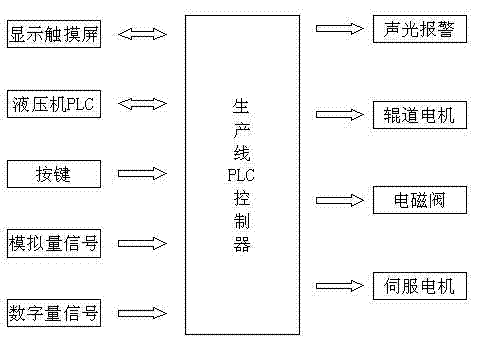

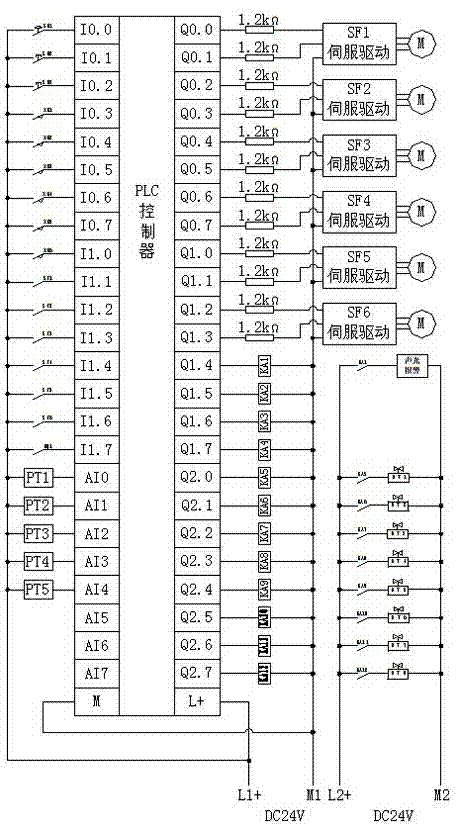

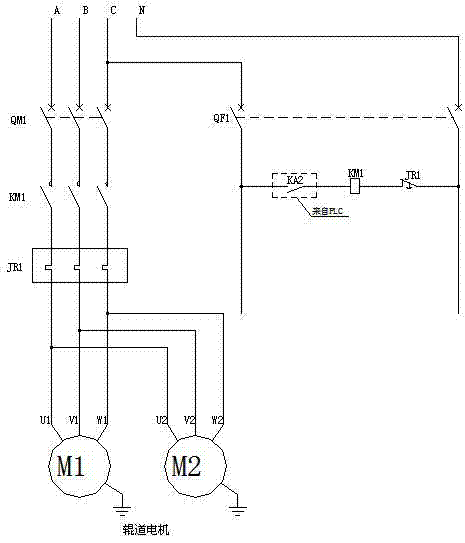

[0026] See figure 1 , The automatic control system of the plate forming production line in this embodiment is composed of a PLC controller, a display touch screen, a hydraulic machine PLC, sound and light alarm, roller table motor, solenoid valve and servo motor, among which:

[0027] The PLC controller mainly completes the sampling, calculation, and precise control of the production line. Its action program is stored in the PLC program memory. Its interfaces include digital input interface, analog input interface, digital output interface and high-frequency pulse interface, MPI communication interface;

[0028] The display touch screen communicates with the PLC controller through the MPI communication method. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com