Method for growth of epitaxial layer of light emitting diode chip

A technology of light-emitting diodes and a growth method, which is applied in the field of epitaxial layer growth of light-emitting diode chips, can solve problems such as reducing the quality of light-emitting diode chips and affecting the internal quantum efficiency of light-emitting diode chips, so as to improve crystal quality and internal quantum efficiency, increase lateral Growth effect, effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An embodiment of the present invention provides a method for growing an epitaxial layer of a light emitting diode chip, the method comprising:

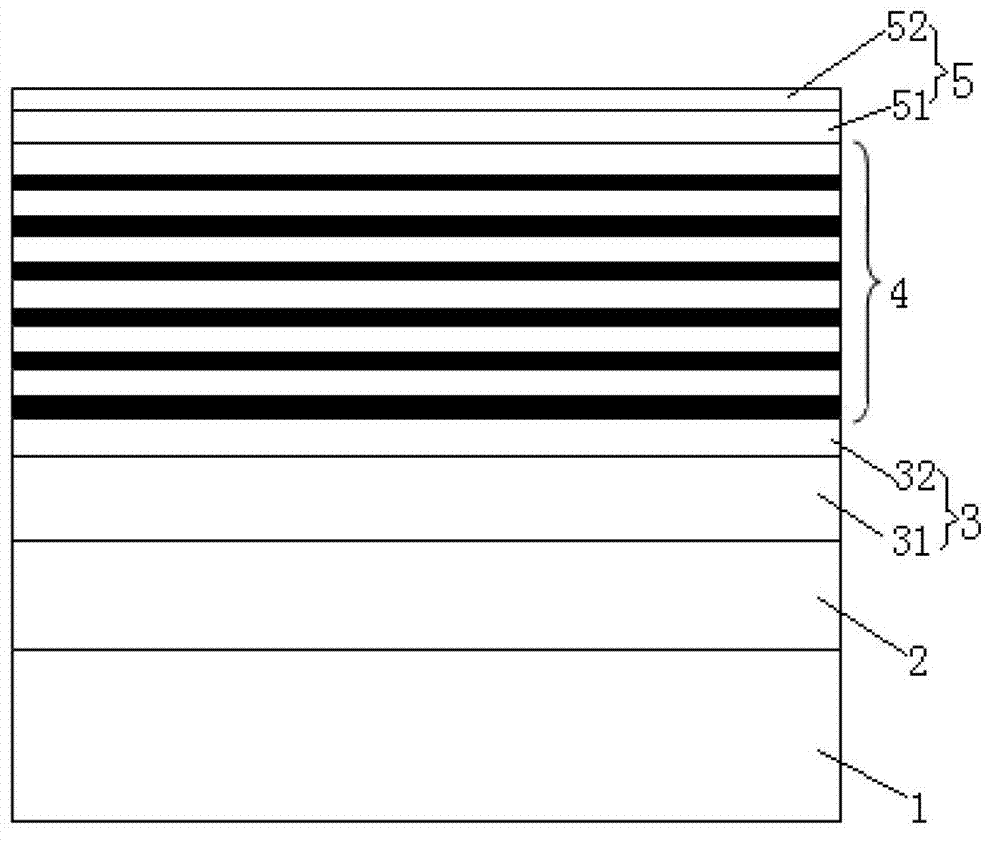

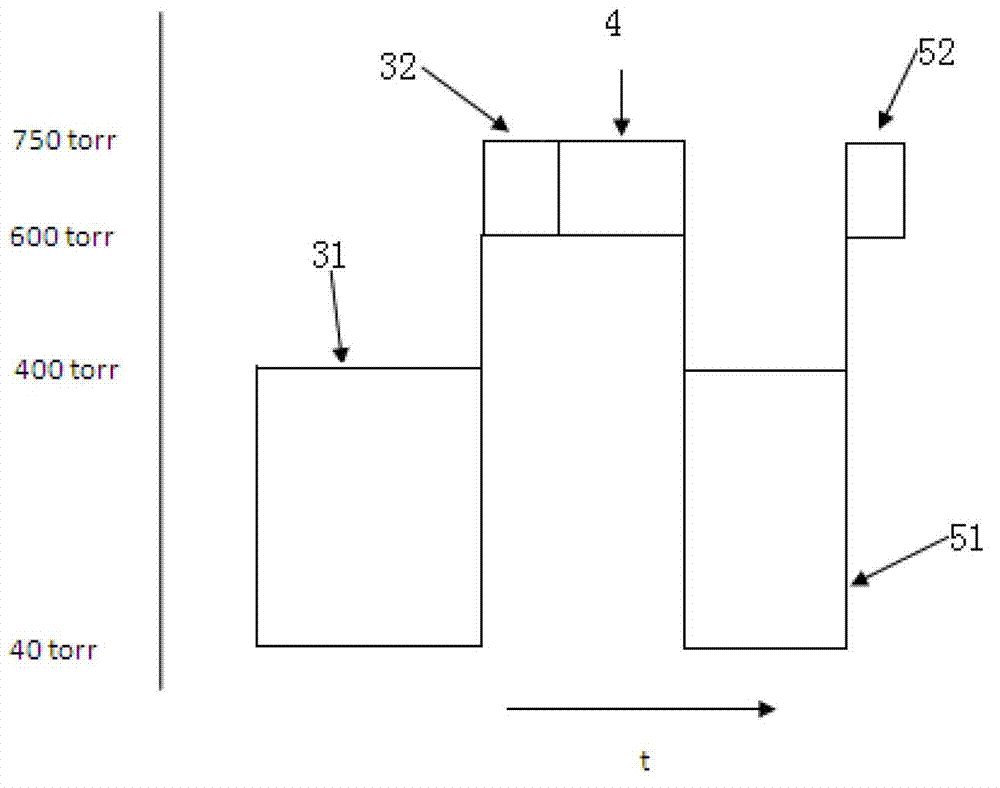

[0026] U-type GaN layer 2, n-type layer 3, quantum well active region layer 4, and p-type layer 5 are sequentially grown on substrate 1 by MOCVD method, such as figure 2 As shown, wherein, the growth pressure of the quantum active region layer 4 is 600-750 torr.

[0027] In specific implementation, this method can be realized through the following steps:

[0028] Step 101: Place the crystal-oriented sapphire substrate on a graphite disk and send it into the reaction chamber, heat the sapphire substrate to 1060° C. for 5 minutes.

[0029] Step 102: growing a 2um thick undoped GaN layer 2 under a low pressure of 200torr.

[0030] Step 103: growing a Si-doped n-type GaN carrier layer 31 with a thickness of 2 um under a low pressure of 40 torr.

[0031] Step 104: growing a Si-doped n-type GaN contact layer 32 with a thickness o...

Embodiment 2

[0038] An embodiment of the present invention provides a method for growing an epitaxial layer of a light emitting diode chip, see figure 2 , the method includes:

[0039] The MOCVD method is used to sequentially grow an undoped GaN layer 2, an n-type layer 3, a quantum well active region layer 4, and a p-type layer 5 on a substrate 1, such as figure 2 As shown, wherein, the growth pressure of the quantum active region layer 4 is 600-750 torr.

[0040] Preferably, the growth pressure of the n-type contact layer 32 is 600-750 torr.

[0041] Further, the growth pressure of the n-type GaN carrier layer 31 is 40-400 torr. In actual growth, in order to increase the growth speed, generally 40-400 torr is used to grow the n-type GaN carrier layer 31 . Apparently, the n-type GaN carrier layer 31 can also be grown with a high voltage of 600-750 torr, which can further increase the cracking effect of the material and reduce the defect density in the material.

[0042] It should be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Growth pressure | aaaaa | aaaaa |

| Growth pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com