Electromagnetic heating device manufacturing method and electromagnetic heating device manufactured by same

The technology of an electromagnetic heating device and manufacturing method is applied in the direction of electric heating device, electric/magnetic/electromagnetic heating, electrical components, etc., which can solve the problems of maintenance amount, large maintenance cost, large difference in vulcanization temperature, and uneven heating of the plate. Achieve the effects of reducing labor intensity, having little impact on ambient temperature, and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

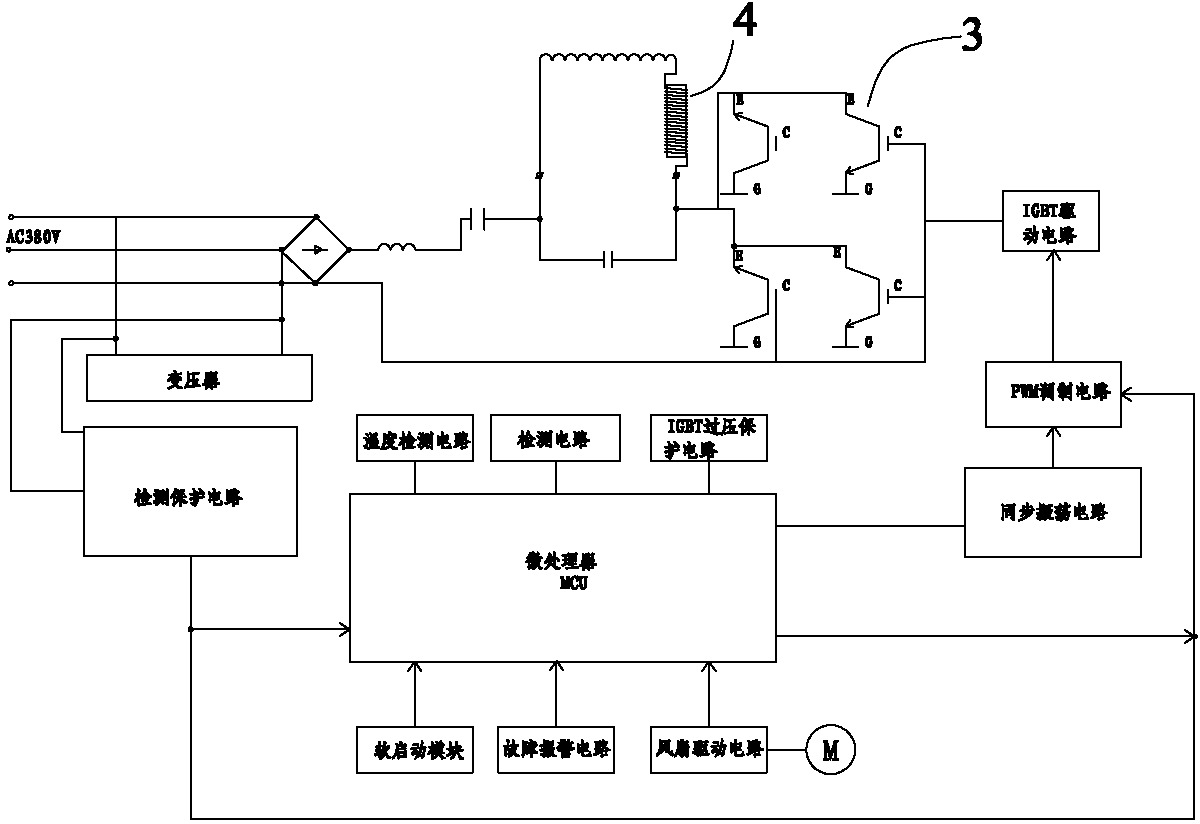

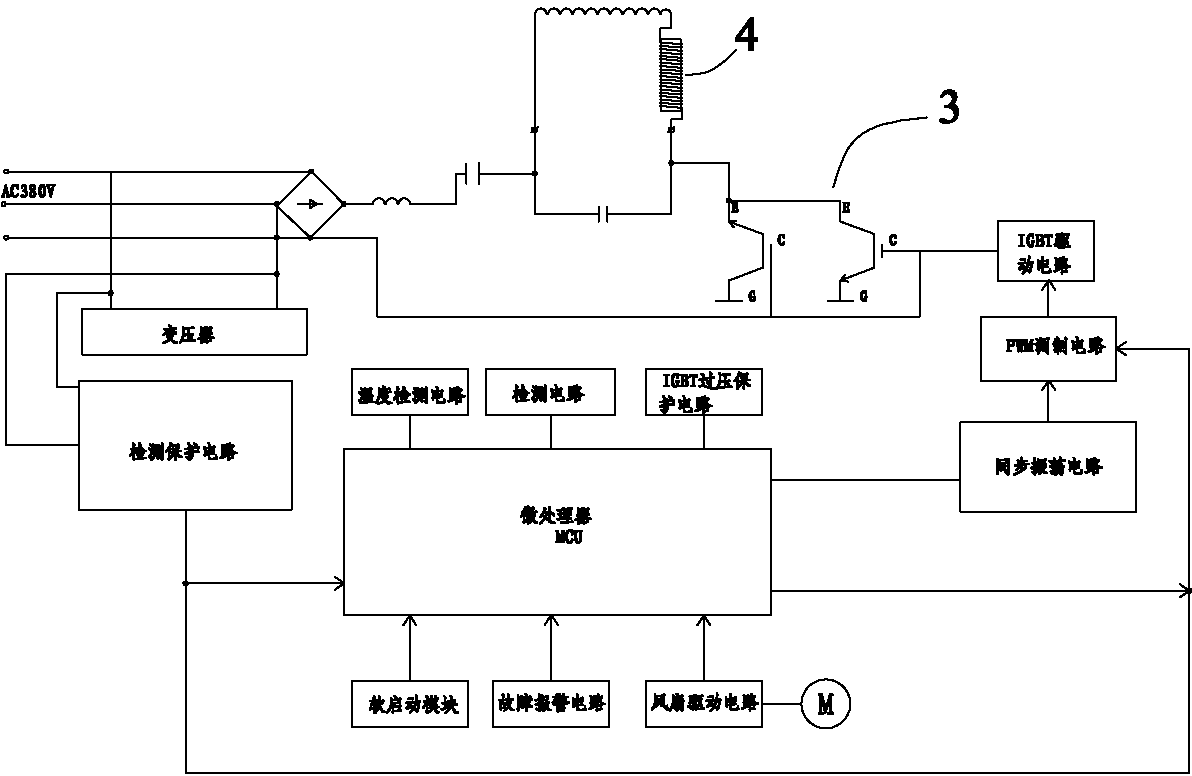

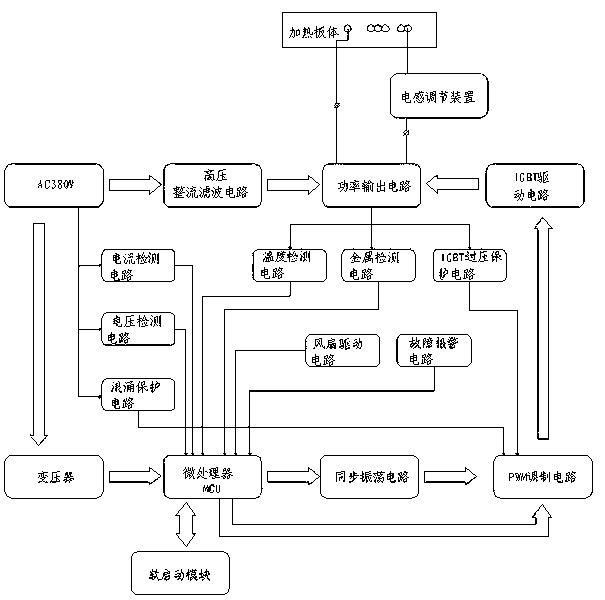

[0028] Example: see Figure 1 to Figure 9 , a manufacturing method of an electromagnetic heating device provided by an embodiment of the present invention, which includes the following steps: (1) making a heating body 1; (2) making an electromagnetic coil 2; (3) milling slots: milling out a A housing slot that matches the profile of the electromagnetic coil 2, and the electromagnetic coil 2 is placed in the housing slot; (4) Assembling: making a topological structure in which the power part is connected by copper strips, which can An electromagnetic heating control board for controlling the working state of the electromagnetic coil 2 is connected with the electromagnetic coil 2 to obtain an electromagnetic heating device.

[0029] The heating body 1 includes a metal substrate 11 that is bonded to two metal plates, and the accommodating groove 12 is arranged on the bonding surfaces of the two metal substrates 11; the electromagnetic coil 2 is made of a copper wire according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com