Metal component coupling structure and device

A technology for metal parts and connecting structures, applied in the field of connecting structures and connecting devices of metal parts, can solve the problems of poor productivity, increased weight and cost of parts, etc., and achieve the effect of high connection strength and high precision connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

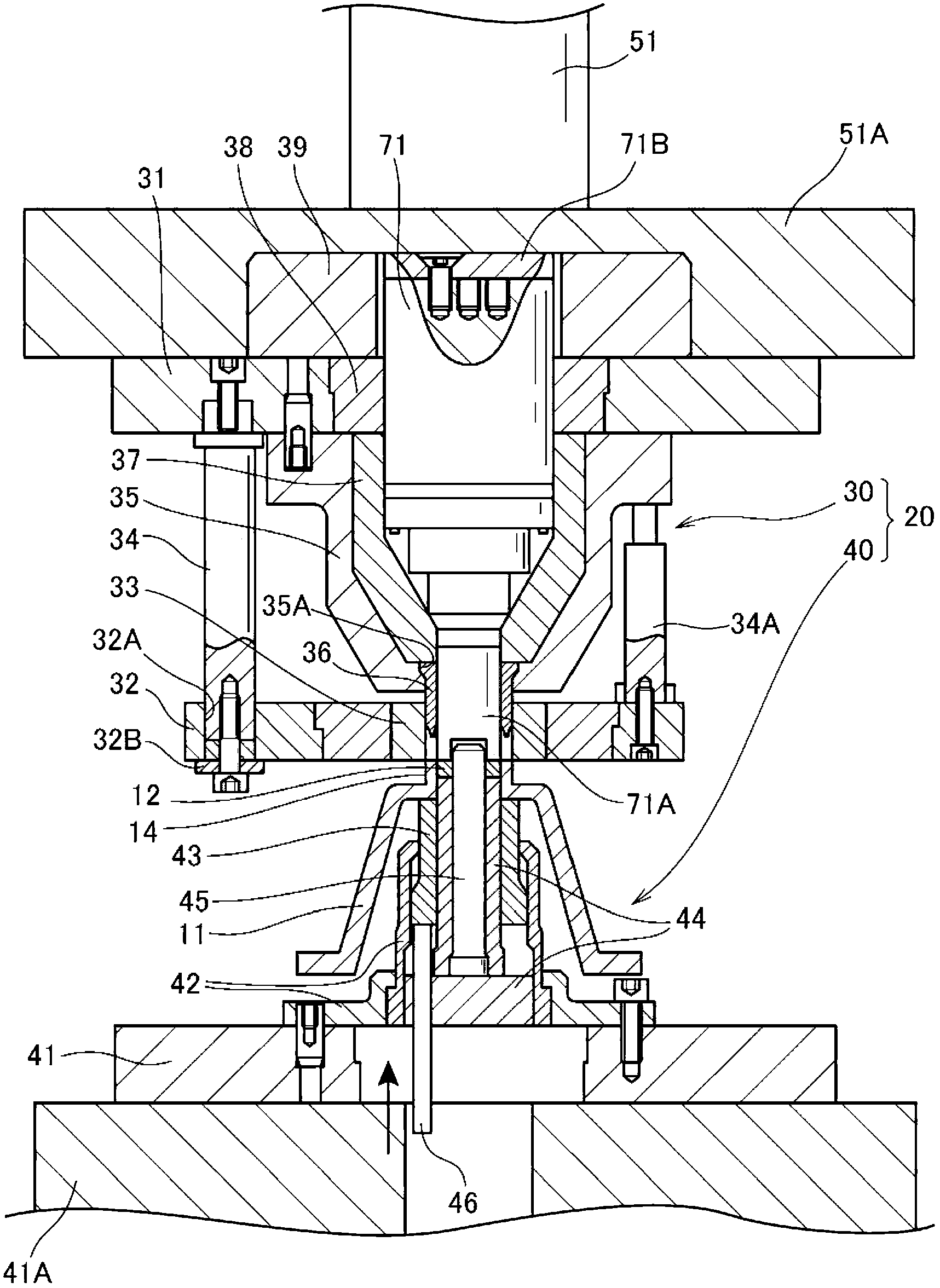

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

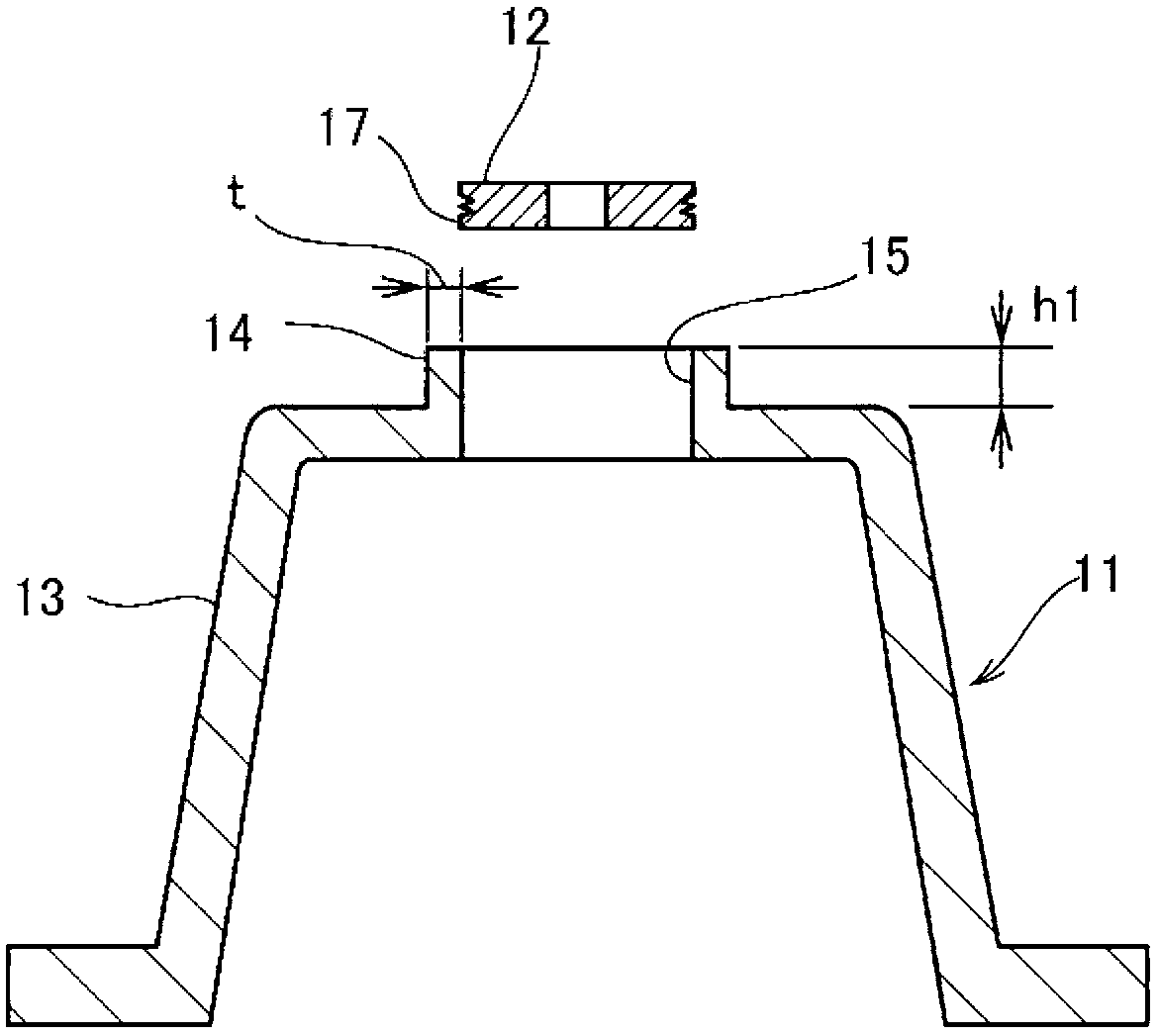

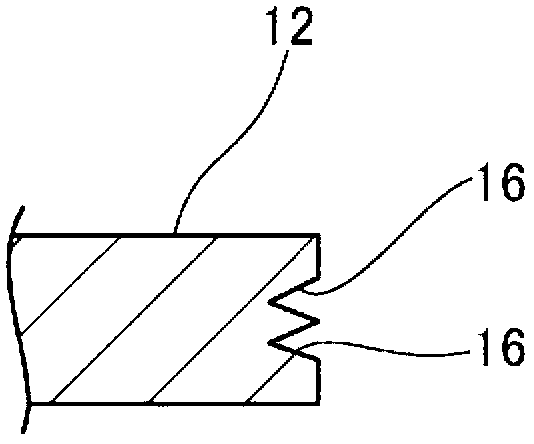

[0048] FIG. 1 shows an example of a first metal member 11 and a second metal member 12 to which the metal member connection structure according to this embodiment can be applied. In addition, the shapes of the first metal member 11 and the second metal member 12 shown in the drawings in this embodiment are merely examples for explaining this embodiment, and the applied parts of this embodiment are not limited to these shapes. .

[0049] The first metal component 11 is a metal frame, and includes: a main body 13 and an annular portion 14 integrally formed with the main body 13 . The opening 15 is formed in the annular portion 14 which is, for example, a thin portion having a thickness t of 3 mm and a height h1 of 6 mm. The first metal component 11 is a molded die-cast product made of aluminum alloy or the like, which is also a material that lacks ductility.

[0050] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com