Durable recycled concrete and preparation method thereof

A recycled concrete and durable technology, applied in the field of concrete, can solve the problems of poor durability of recycled concrete, and achieve the effects of improving compatibility, reducing infiltration, and lasting expansion state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0030] Preparation of mulberry leaf powder: Harvest mature mulberry leaves, freeze them at -10°C for 12 hours, take out the mulberry leaves and thaw them, then add 0.1wt% sodium bicarbonate solution to water at 90°C, and place the thawed mulberry leaves in it for 3 minutes , taking out the blanched mulberry leaves, washing them with clear water, drying the rinsed mulberry leaves in an environment of 90° C., and crushing them into uniform powder to obtain mulberry leaf powder.

[0031] Unless otherwise specified, the raw materials used in the following embodiments can all come from commercially available sources.

Embodiment 1

[0034] This application discloses a durable recycled concrete, which includes the following raw materials: cement, recycled coarse aggregate, recycled fine aggregate, water, mulberry leaf powder, and water reducer PCE. The preparation process includes the following steps:

[0035] S1. Preparation of concrete; mix 60 parts of cement, 50 parts of recycled coarse aggregate, 40 parts of recycled fine aggregate, 10 parts of mulberry leaf powder and 1 part of water reducing agent PCE, then add 40 parts of water and stir evenly to prepare Get concrete.

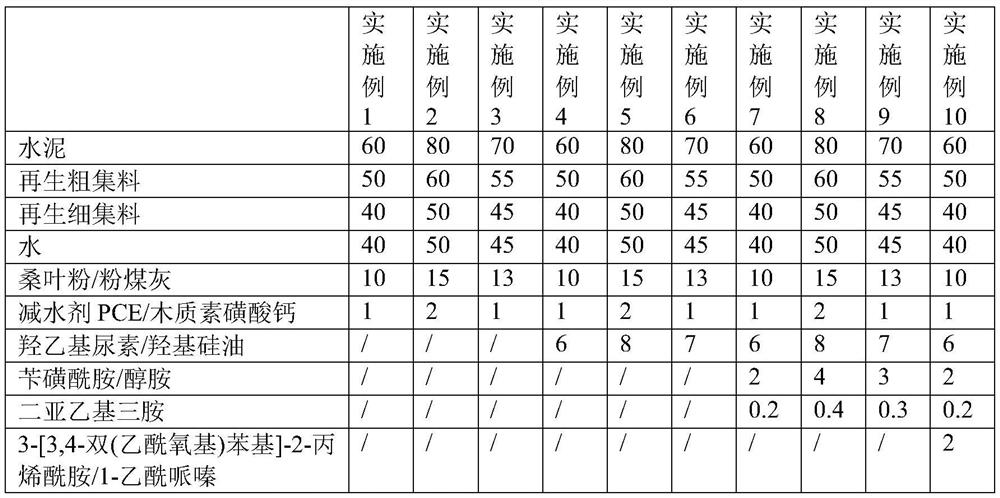

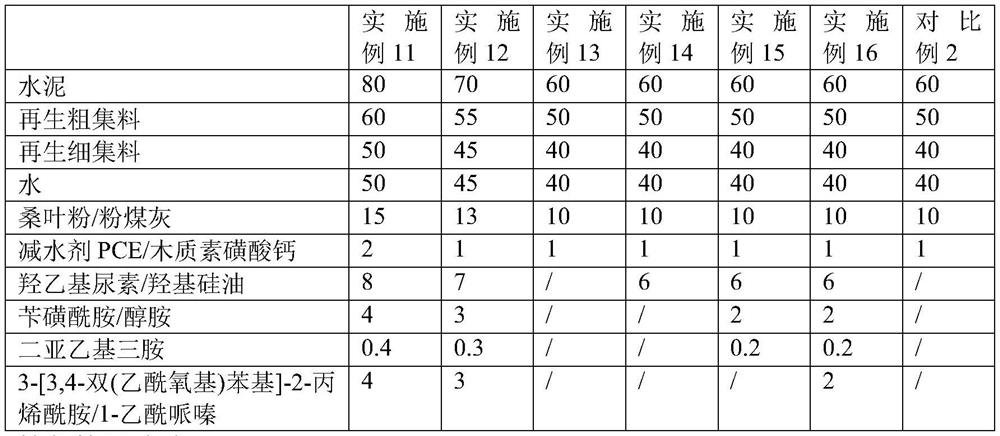

[0036] The content of each component is shown in Table 1-1 below.

Embodiment 2

[0038] This application discloses a durable recycled concrete, which includes the following raw materials: cement, recycled coarse aggregate, recycled fine aggregate, water, mulberry leaf powder, and water reducer PCE. The preparation process includes the following steps:

[0039] S1. Preparation of concrete; mix 80 parts of cement, 60 parts of recycled coarse aggregate, 50 parts of recycled fine aggregate, 15 parts of mulberry leaf powder and 2 parts of water reducer PCE, then add 50 parts of water and stir evenly to prepare Get concrete.

[0040] The content of each component is shown in Table 1-1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com