Preparation method of plastic woven bag color printing film

A technology of plastic woven bags and color printing films, which is applied to flat products, other household appliances, household appliances, etc. It can solve the problems of poor ink adhesion and ink easy to fall off, so as to improve adhesion performance, reduce friction coefficient, and inhibit crack development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

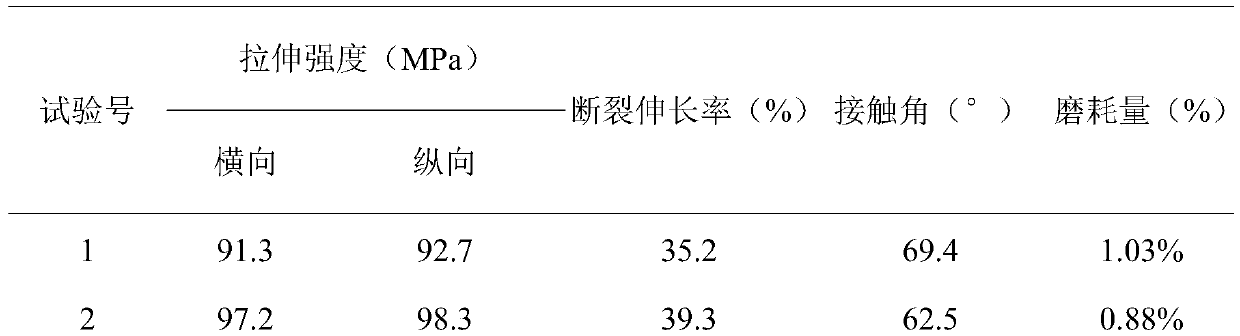

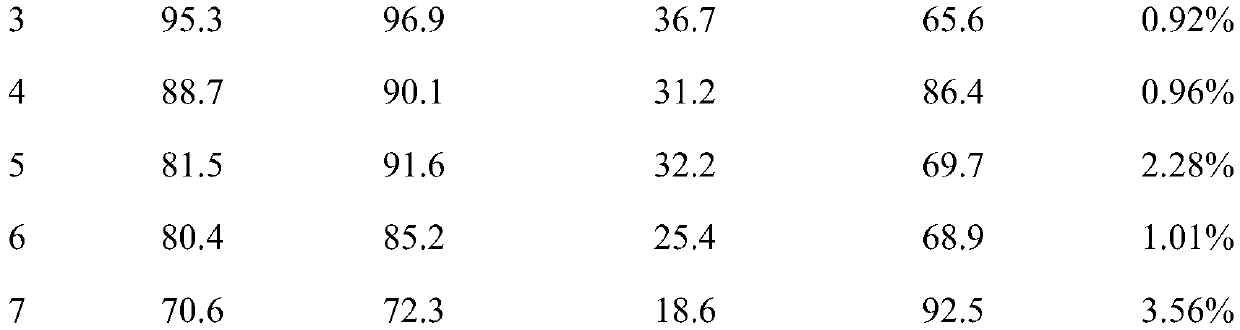

Examples

Embodiment 1

[0030] A method for preparing a plastic woven bag color printing film, the plastic woven bag color printing film includes an ink layer and an outer coating; the preparation method comprises the following steps:

[0031] Step S1: Mix 80 parts of ethanol and 40 parts of ethyl acetate as ink solvent raw materials to prepare an ink solvent and store it for later use;

[0032] Step S2: 30 parts of ink coloring raw material pigment, 5 parts of binder, 5 parts of hydrogenated dipolylinoleyl alcohol, 3 parts of cycloethoxypolymethylsiloxane, 1 part of aluminum sec-butoxide, stabilizer epoxy resin 3 parts were put into a blender for dispersing and stirring to prepare a colored mixture;

[0033] Step S3: Pour out the stirred coloring mixture, put it into the ink solvent, adjust the pH value to 8, and prepare the ink;

[0034] Step S4: Pour 60 parts of LLDPE, 20 parts of LDPE, 5 parts of filler, 3 parts of antioxidant, and 4 parts of toughening agent dipropylene glycol salicylate into a...

Embodiment 2

[0041] A method for preparing a plastic woven bag color printing film, the plastic woven bag color printing film includes an ink layer and an outer coating; the preparation method comprises the following steps:

[0042] Step S1: Mix 100 parts of ethanol and 60 parts of ethyl acetate as ink solvent raw materials to prepare an ink solvent and store it for later use;

[0043] Step S2: 40 parts of ink coloring raw material pigment, 10 parts of binder, 10 parts of hydrogenated dimerized linoleyl alcohol, 5 parts of cycloethoxy polymethylsiloxane, 3 parts of aluminum sec-butoxide, stabilizer stearic acid 5 parts of lead are put into a stirrer for dispersing and stirring to prepare a colored mixture;

[0044] Step S3: Pour out the stirred coloring mixture, put it into the ink solvent, adjust the pH value to 9, and prepare the ink;

[0045] Step S4: Pour 80 parts of LLDPE, 40 parts of LDPE, 8 parts of filler, 5 parts of antioxidant, and 6 parts of toughening agent dipropylene glycol ...

Embodiment 3

[0052] A method for preparing a plastic woven bag color printing film, the plastic woven bag color printing film includes an ink layer and an outer coating; the preparation method comprises the following steps:

[0053] Step S1: Mix 90 parts of ethanol and 50 parts of ethyl acetate as ink solvent raw materials to prepare an ink solvent and store it for later use;

[0054] Step S2: 35 parts of ink coloring raw material pigment, 8 parts of binder, 8 parts of hydrogenated linoleyl alcohol, 4 parts of cycloethoxypolymethylsiloxane, 2 parts of aluminum sec-butoxide, stabilizer epoxy resin 4 parts were put into a blender for dispersing and stirring to prepare a colored mixture;

[0055] Step S3: Pour out the stirred coloring mixture, put it into the ink solvent, adjust the pH value to 9, and prepare the ink;

[0056] Step S4: Pour 70 parts of LLDPE, 30 parts of LDPE, 7 parts of filler, 4 parts of antioxidant, and 5 parts of toughening agent dipropylene glycol salicylate into a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com