Gasoline hydrodesulfurization and membrane unit to reduce mercaptan type sulfur

A hydrodesulfurization and mercaptan technology, applied in the direction of hydroprocessing process, membrane, membrane technology, etc., can solve problems such as blockage of heat exchangers and flow pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

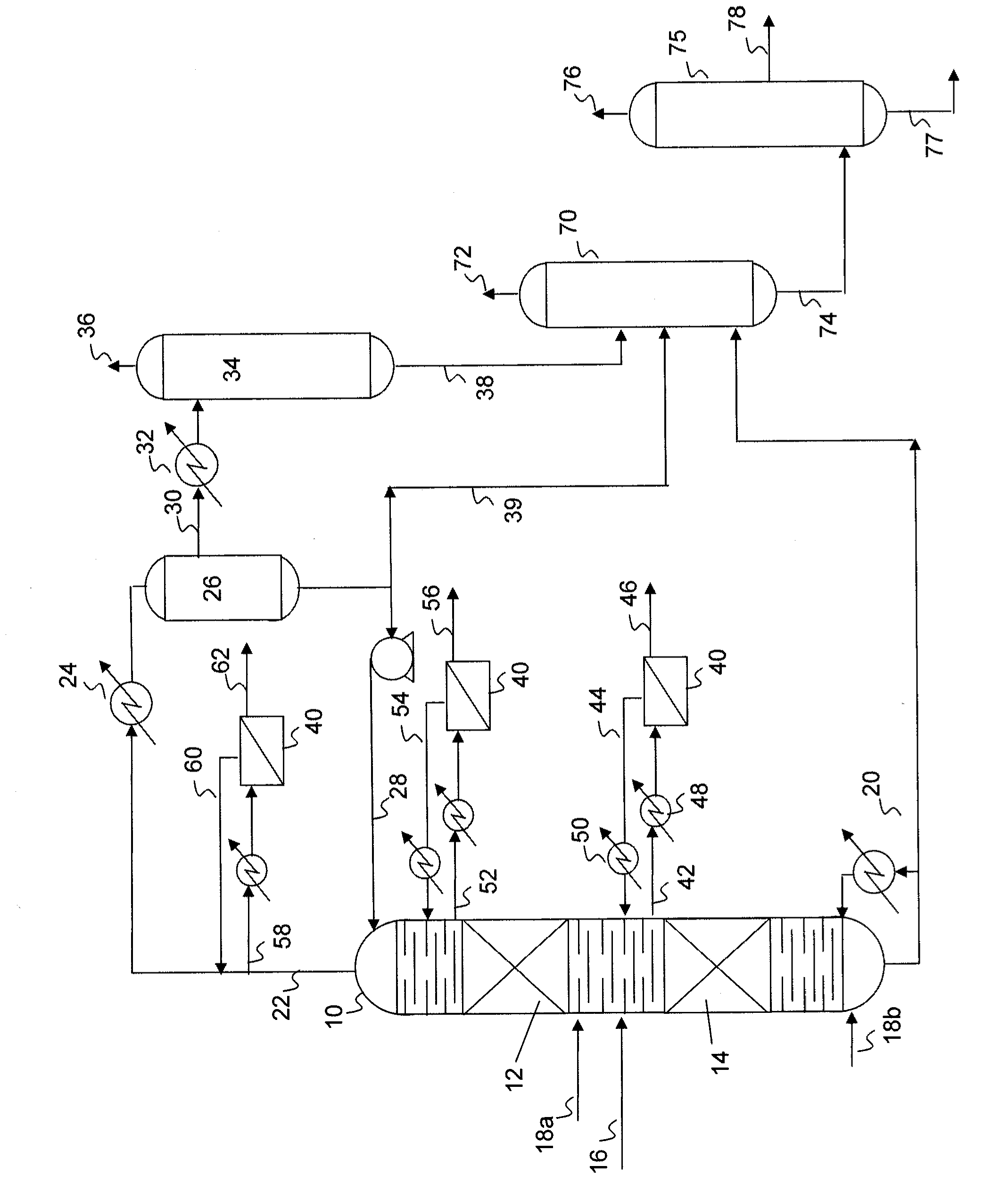

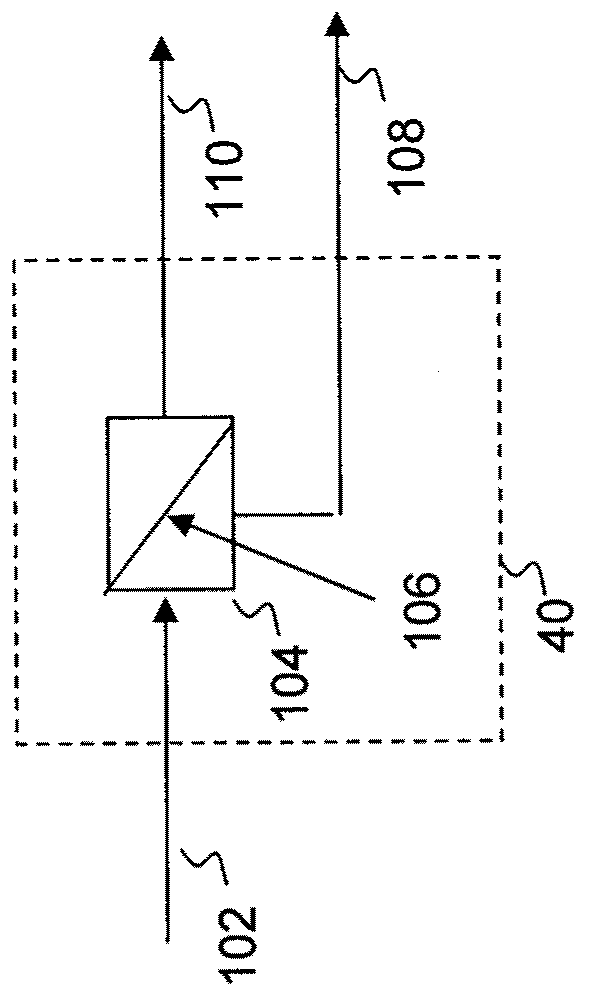

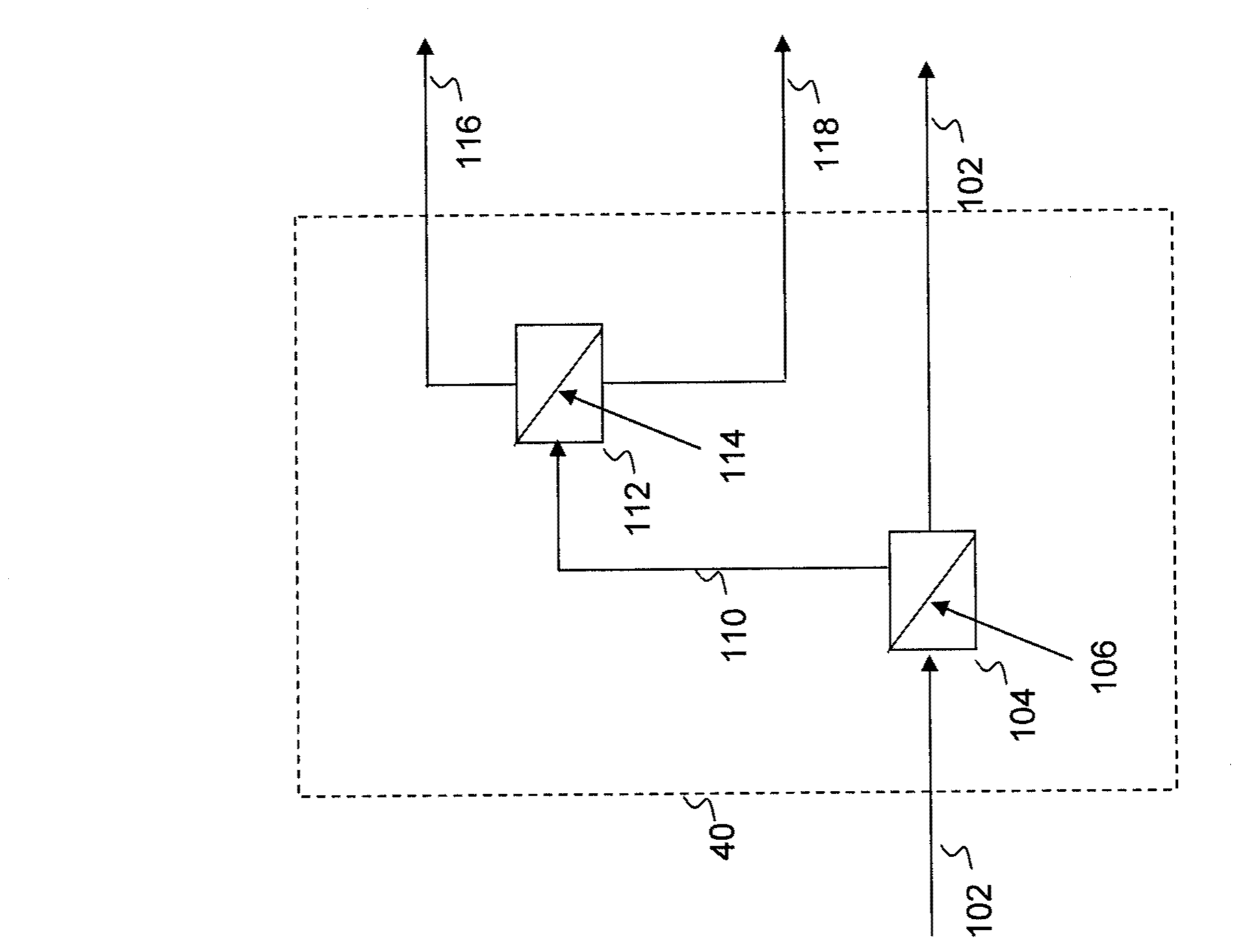

[0030] As used herein, "recombinant mercaptan" refers to not the mercaptan in the feed of this process, but the H produced by the hydrogenation of sulfur-containing compounds in this process 2 Mercaptans are the reaction products of S and olefins in the feed. Therefore, the recombinant mercaptans need not be the same as those destroyed by the hydrodesulfurization of the first part of the process of the invention, although they may be the same. It is believed that the catalytic distillation hydrodesulfurization process of the present invention basically decomposes all mercaptans in the feed, and the small amounts of mercaptans observed in the product stream are usually recombinant mercaptans. Although the catalytic distillation reaction is superior to the prior art direct hydrogenation for removing mercaptans, the dynamic system of catalytic distillation allows sufficient time for some undesired recombination reactions to occur. Therefore, in the embodiments disclosed herein, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com