Multi-groove circulating silicon wafer cleaning machine

A technology for cleaning silicon wafers and cleaning tanks, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem that overflow liquid cannot be recycled, increase the production cost of silicon wafers, and frequent cleaning tanks Change water and other issues to achieve the effect of reducing liquid pollution, reducing water consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

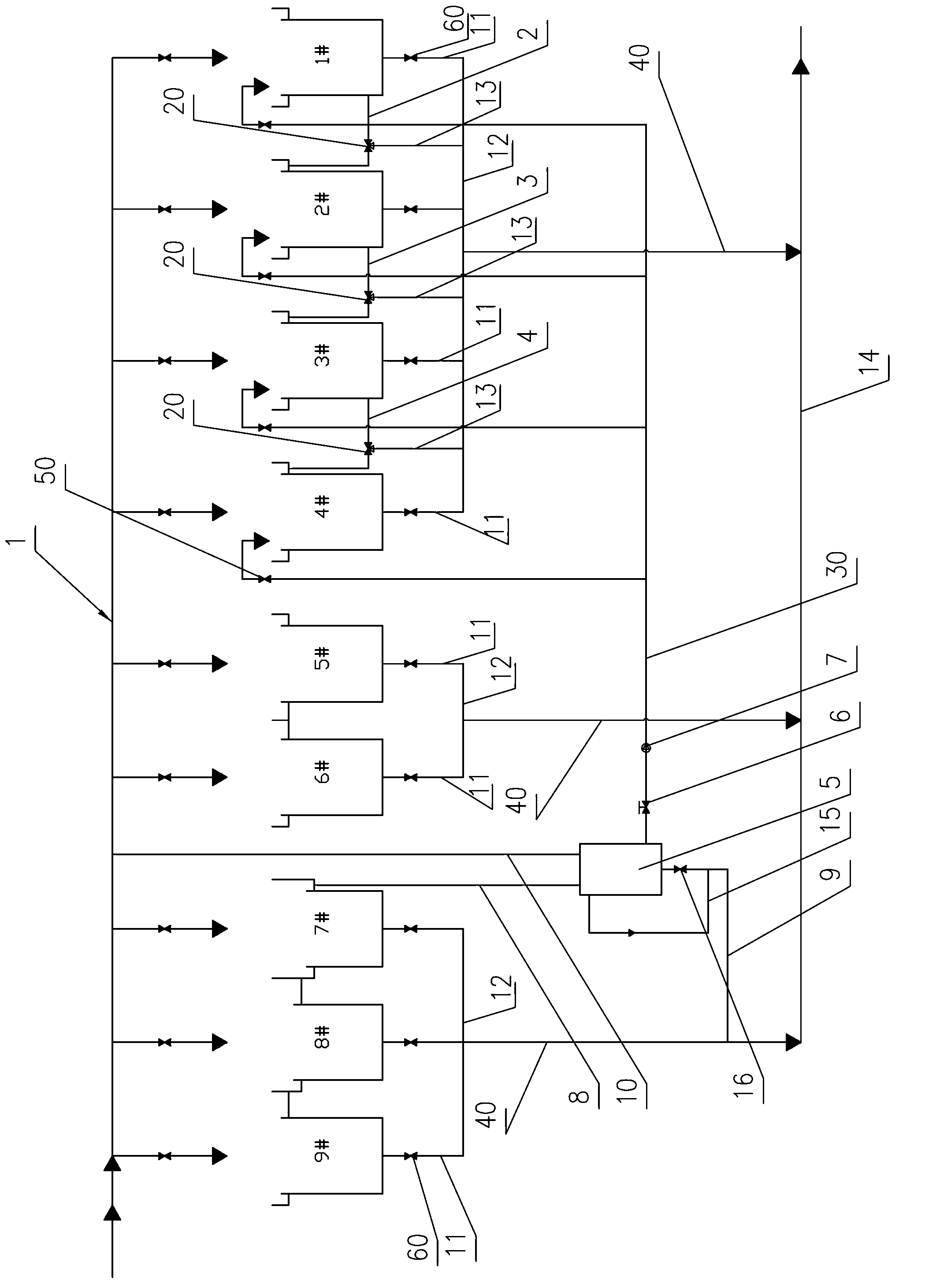

[0029] Such as figure 1Shown is a multi-groove ultrasonic circulation silicon wafer cleaning machine of the present invention, including a cuboid casing, a cleaning tank arranged in the casing, a water supply pipeline 1 for providing pure water for the cleaning tank, and a The drainage pipeline for the discharge of the cleaning liquid in the cleaning tank. In this embodiment, the cleaning tank is 9 sequentially arranged tanks, mainly composed of dual-function cleaning tanks (No. 1-4 Cleaning tank 1#-4#), chemical cleaning tank for alkaline cleaning with liquid medicine (the fifth cleaning tank 5#, sixth cleaning tank 6#), water washing cleaning tank for pure water cleaning (the seventh cleaning tank 7 #, the 8th cleaning tank 8# and the 9th cleaning tank 9#), among them, the water washing cleaning tank (the 9th cleaning tank 9#) in the last order is the slow lifting pre-elution tank, and the 1st-4th cleaning tank Between two adjacent tanks, there is an overflow pipe that comm...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that there are 6 cleaning tanks, of which, there are 2 dual-function cleaning tanks, which are the first and second cleaning tanks, and 2 chemical cleaning tanks, which are the third cleaning tanks. , 4 cleaning tanks, there are 2 washing tanks, which are the 5th and 6th cleaning tanks, and the slow pre-elution tank is the 6th cleaning tank.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that there are 12 cleaning tanks, among which, there are 5 dual-function cleaning tanks, which are the 1st to 5th cleaning tanks, and 3 cleaning tanks, which are the 6th cleaning tanks. -8 cleaning tanks, there are 4 washing tanks, which are the 9th to 12th cleaning tanks, and the slow lifting pre-elution water tank is the 12th cleaning tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com