Steel plate stacker crane

A palletizer and steel plate technology, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of difficult maintenance, low efficiency, time-consuming and laborious maintenance of palletizers, and achieve the improvement of the overall technical level and the convenience of installation and maintenance. , the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0016] In the accompanying drawings, the components are numbered as follows:

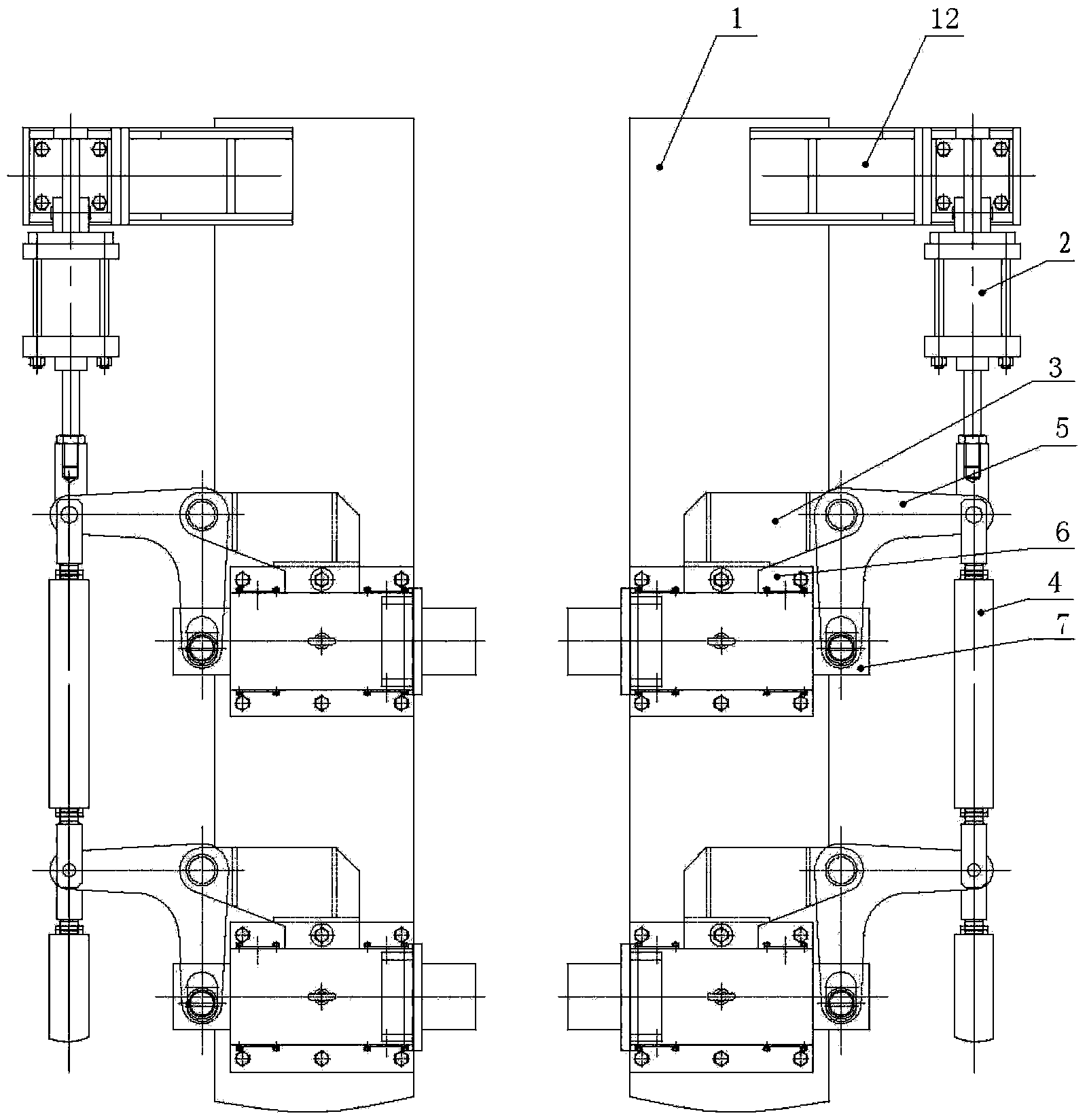

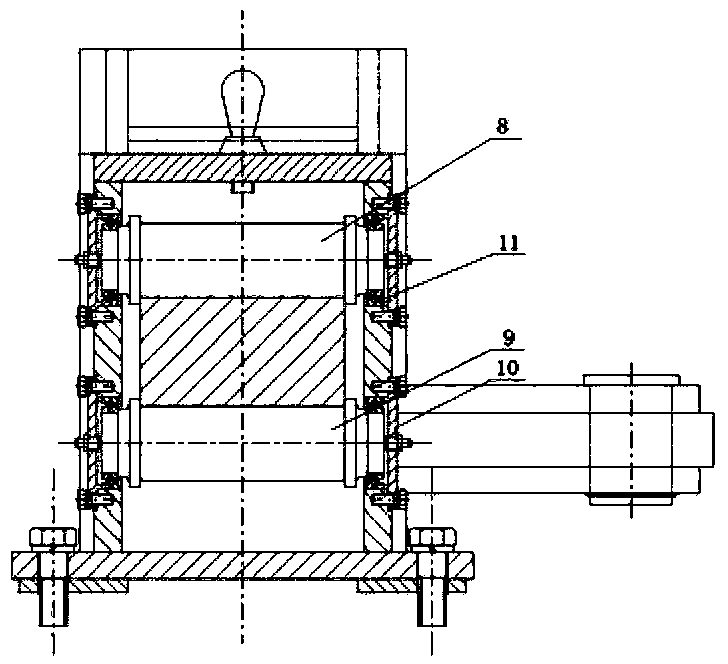

[0017] Fixed beam 1, cylinder 2, fixed earring 3, pull rod 4, swing rod 5, fixed support 6, slider 7, upper row of rollers 8, lower row of rollers 9, gland 10, rolling bearing 11, pillar 12.

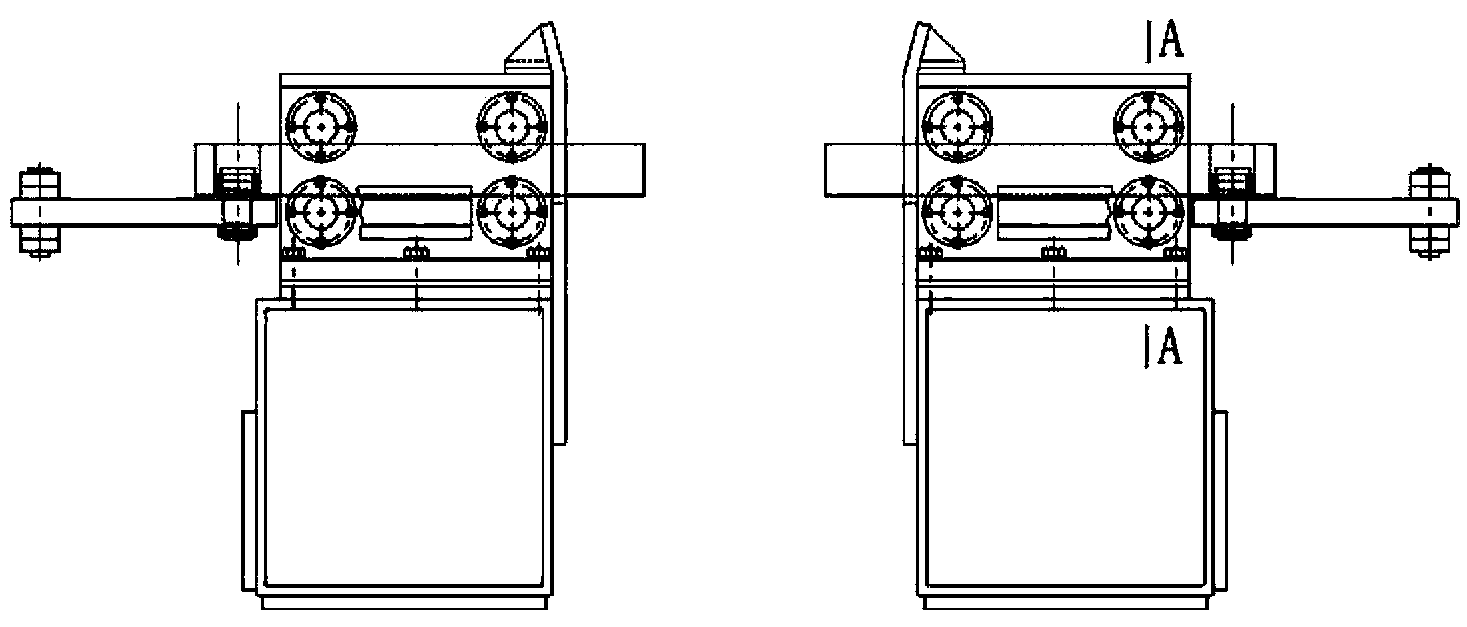

[0018] Such as figure 1 , 2 Shown: a steel plate palletizer, including two parallel fixed beams 1 of equal length, a cylinder 2 is installed at one end of the fixed beam 1 through a pillar 12, and a plurality of fixed supports 6 are installed on the fixed beam 1; The upper row of rollers 8 and the lower row of rollers 9 are installed in the inner cavity of the support 6, and the shaft ends of the upper row of rollers 8 and the lower row of rollers 9 are equipped with rolling bearings 11, and the outside of the rolling bearings 11 is connected together by a gland 10 and a fixed support 6; The sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com