PP (Propene Polymer) fiber composite board and production method

A fiber compounding and production method technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of easy mildew on the surface of hemp felt board and medium fiber board, and the input of presses and flat molds Large, easy-to-produce warping and deformation of the board, to reduce the cost of secondary molding and equipment investment, to solve the effect of being susceptible to moisture and mildew, and reducing shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

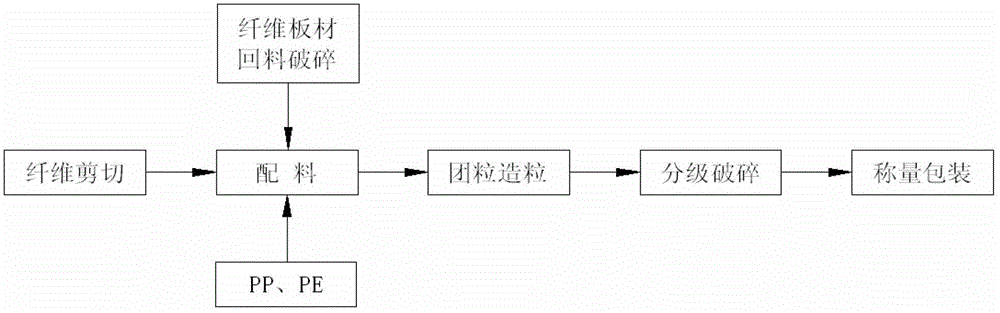

[0042] The temperature of the preparation process of the pellets is 170-195 degrees.

[0043] The particle size of the crushing and grading of aggregates is 1-12mm.

[0044] In the granulation process, the mass ratio of fiber, fiber board material, PP and PE is 30-35:35-30:15-20:15-10.

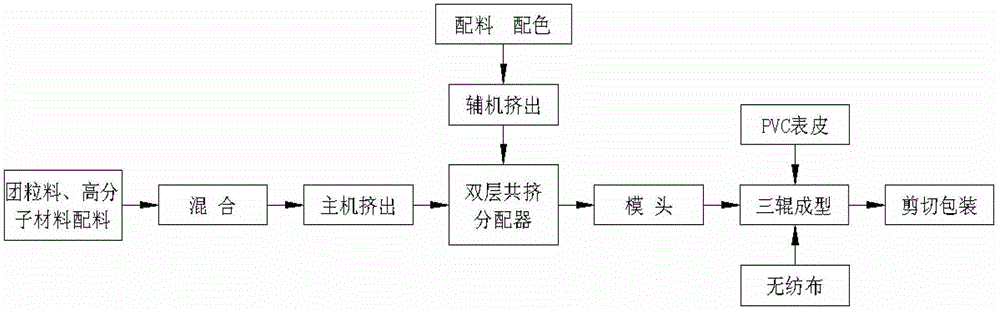

[0045]The mass ratio of the extruded material of the substrate layer is 60-75:10-15:5-10:3-8:3-5 of pellets, PP, PE, POE, and additives.

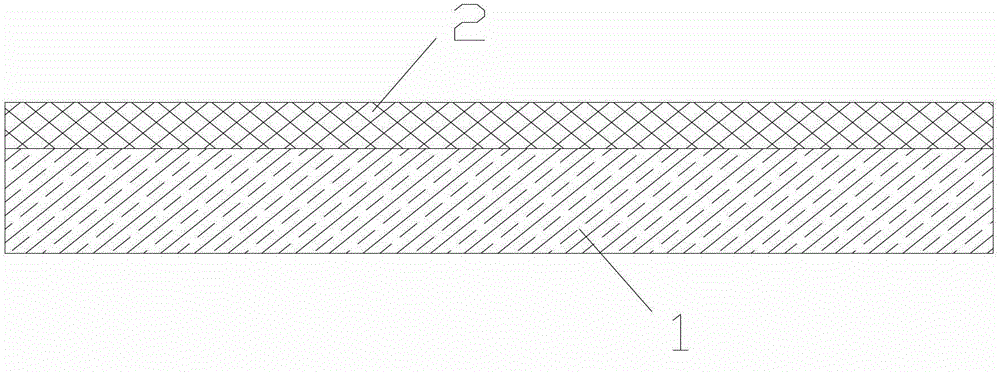

[0046] The extruded material of the substrate layer has a thickness of 1-5mm.

[0047] The mass ratio of extruded material in the surface layer is PP, and the mass ratio of color masterbatch is 95:5.

[0048] The extruded material of the surface layer has a thickness of 20-80 filaments.

[0049] The non-woven fabric composited with the lower layer of the base material is spunlace non-woven fabric 40~60g / m 2 , Acupuncture non-woven fabric 70~90g / m 2 .

[0050] The thickness of the PVC leather compounded on the surface is 0.5-1.2mm.

[0051] The length...

Embodiment 1

[0055] Agglomerate material preparation, jute shear length 60mm, felt board return crushed material, 150#PP powder, 2426PE pellets, additives, etc., respectively carry out aggregate material granulation according to the ratio of 35:35:18:10:2, graded crushing Particle size 8mm.

[0056] Extrusion material preparation, substrate layer main extruder materials: pellets, F401PP, 8101PP, 5000SPE, general-purpose POE, additives, etc., respectively poured into the mixing mixer according to the ratio of 70:8:10:6:5:1 Mixing; the material of the surface layer paving extruder: 8101PP, color masterbatch, etc. are mixed at a ratio of 95:5, and the mixed materials are poured into the silo of the paving extruder; sheet cloth base spunlace non-woven fabric 40g / m2.

[0057] Sheet extrusion molding, surface layer auxiliary extruder screw temperature is 160-195 degrees, substrate layer main extruder screw temperature is 165-195 degrees, co-extrusion distributor and die head temperature is 190...

Embodiment 2

[0059] Agglomerate material preparation, felt board recycled crushed material, 50#PP powder, 2426PE pellets, additives, etc., were granulated according to the ratio of 70:18:10:2 respectively, and the particle size of graded crushing was 10mm.

[0060] Extrusion material preparation, substrate layer main extruder materials: pellets, F401PP, 8101PP, 5000SPE, general-purpose POE, additives, etc., respectively poured into the mixing mixer according to the ratio of 65:8:10:8:6:3 Mixed; surface layer material: 0.8 spunlace cloth-based PVC leather; sheet cloth-based needle-punched non-woven fabric 80g / m2.

[0061] Sheet extrusion molding, surface layer auxiliary extruder screw temperature is 160-195 degrees, substrate layer main extruder screw temperature is 165-195 degrees, co-extrusion distributor and die head temperature is 190-210 degrees, base The mixed material of the material layer is dehumidified, melted and matured by the main extruder, and the matured material is sent to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com