Vehicle drive control system

A vehicle and driving force technology, which is applied in the field of vehicle drive control devices, can solve problems such as inappropriate filter coefficients, natural frequency deviations of the drive system, and inability to drive system mechanical resonance attenuation, and achieve the effect of suppressing mechanical resonance and preventing deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

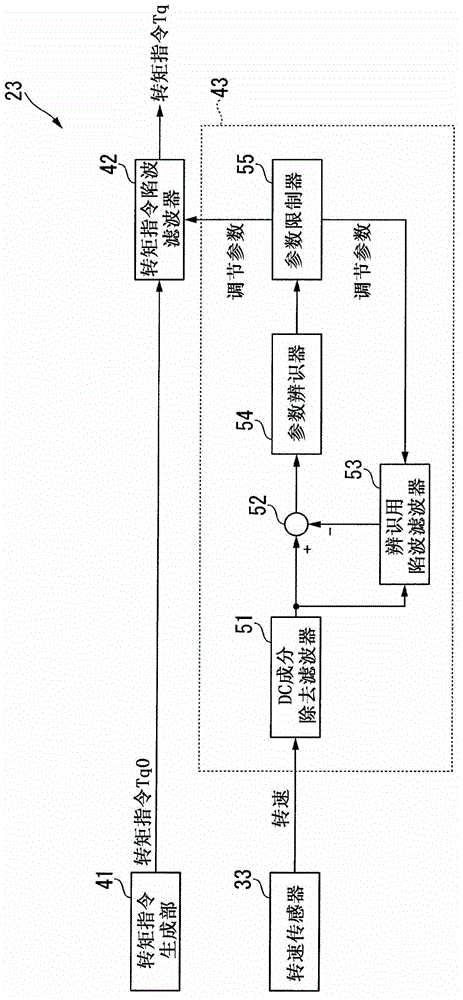

[0035] Next, a vehicle drive control device according to an embodiment of the present invention will be described with reference to the drawings.

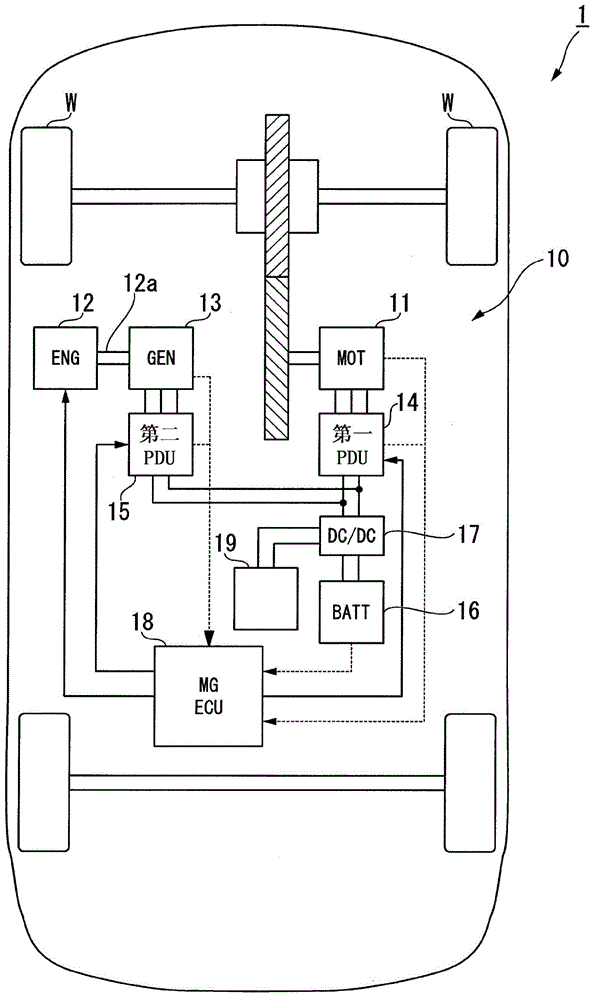

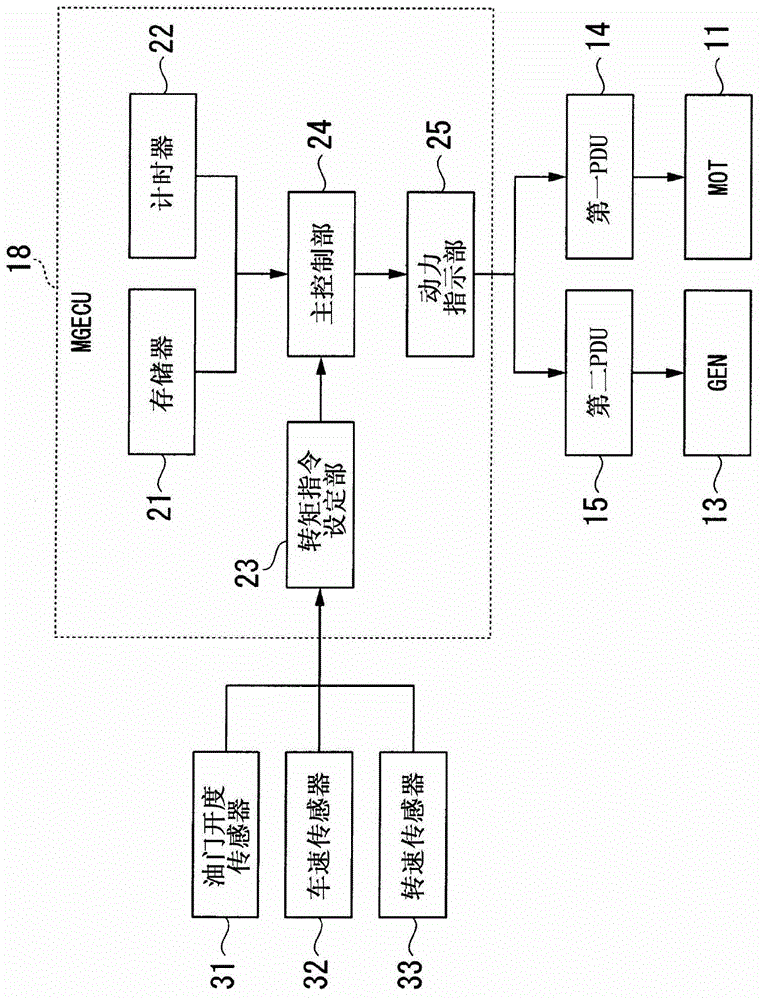

[0036] The drive control device 10 for a vehicle according to the present embodiment is mounted on, for example, figure 1 In the shown hybrid vehicle 1 , the hybrid vehicle 1 is, for example, a series type hybrid vehicle in which a running motor (MOT) 11 is connected to drive wheels W, and a power generation motor (GEN) 13 is connected to an internal combustion engine (ENG) The crankshaft 12a of 12 is connected.

[0037] Each motor 11 , 13 is, for example, a three-phase DC brushless motor or the like, and is connected to each power transmission unit (PDU) 14 , 15 that controls each motor 11 , 13 .

[0038] Each of the PDUs 14 and 15 is configured to include, for example, a PWM inverter based on pulse width modulation (PWM) including a bridge circuit formed by bridge-connecting switching elements such as a plurality of transistors. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com