Warm-mix hard asphalt and preparation method thereof

A technology of hard bitumen and matrix bitumen, which is used in building thermal insulation materials, building components, climate change adaptation, etc. , the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

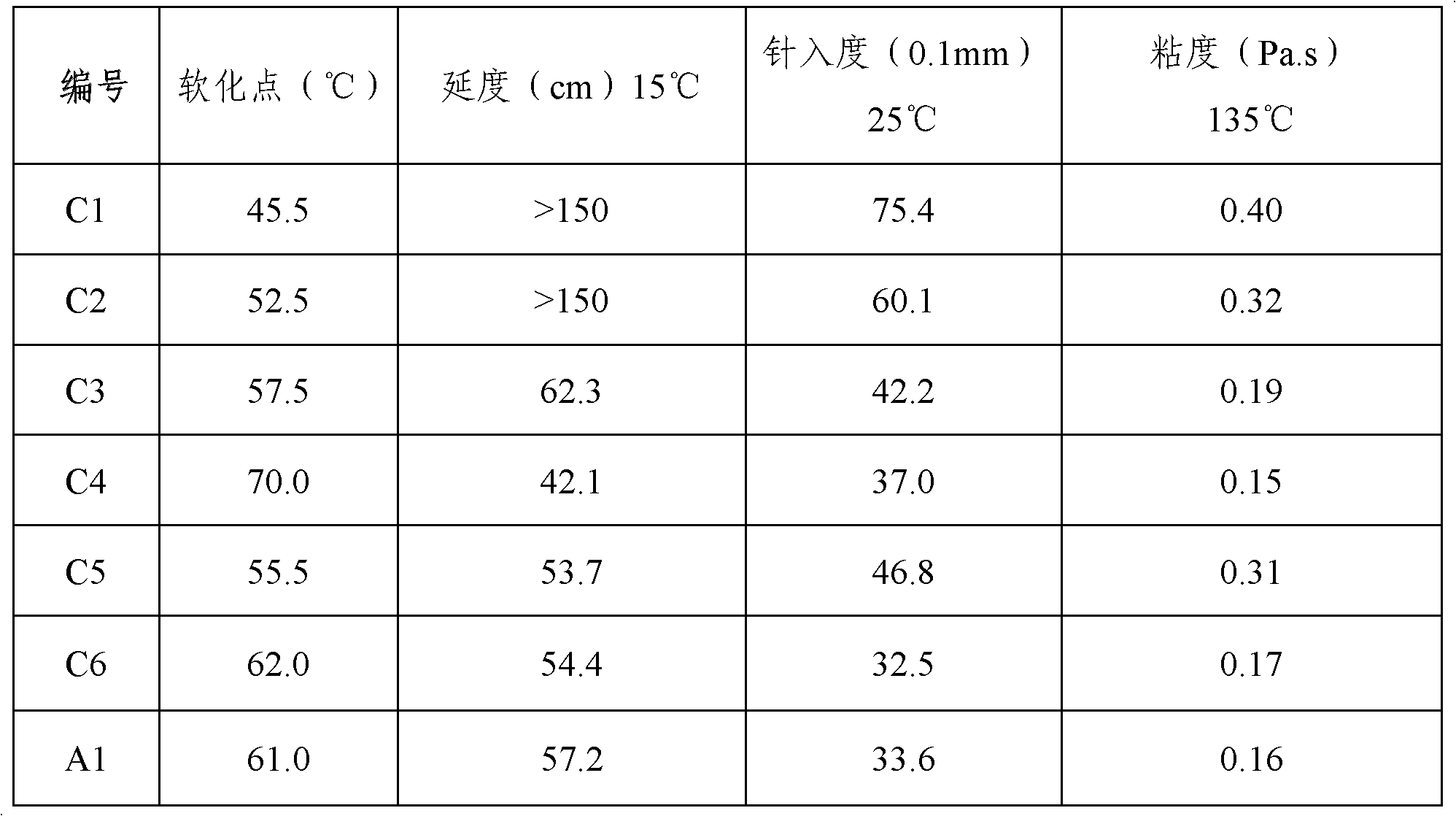

[0045] Add 10 kg of waste polyethylene cracking wax (RPEW of Shanghai Heyuan Plastic Technology Co., Ltd.) and 5 kg of petroleum resin (produced by Daqing Huake Co., Ltd.) P90), then add polyethylene wax grafted maleic anhydride (MP wax produced by Hangzhou Junyi Company) and silane coupling agent (Si-69 of Jiangsu Aiteen Polymer Material Co., Ltd.) each 0.25 kg, at 150 Stir at °C for 30 minutes. The comprehensive performance index of the asphalt (No. A1) is listed in Table 1 below.

[0046] A1 compared with C1: Compared with unmodified asphalt C1, modified asphalt A1, polyethylene wax grafted with maleic anhydride and silane coupling agent have little effect on the viscosity, penetration and softening point of asphalt.

[0047] Comparing A1 with C3: Compared with modified asphalt C3, the added petroleum resin in modified asphalt A1 reduces the needle penetration, increases the softening point, and has little effect on the viscosity.

[0048] A1 vs. C4: Modified bitumen A1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com