Warp knitting machine with hairness removal function

A warp knitting machine and hair removal technology, applied in the field of warp knitting machines, can solve problems such as no relevant research, affecting knitting operations, etc., and achieve the effect of reducing hairiness deposition, low cost and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

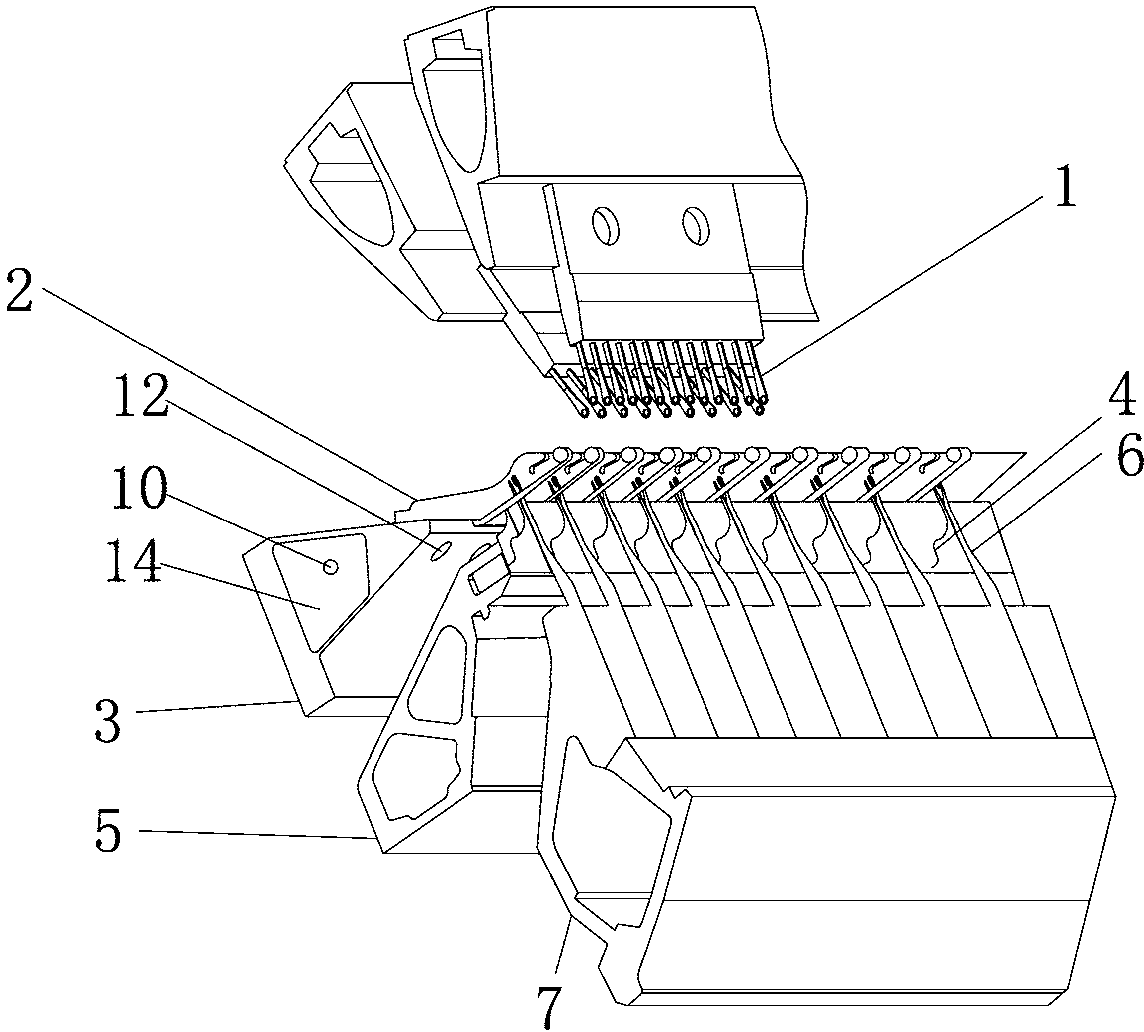

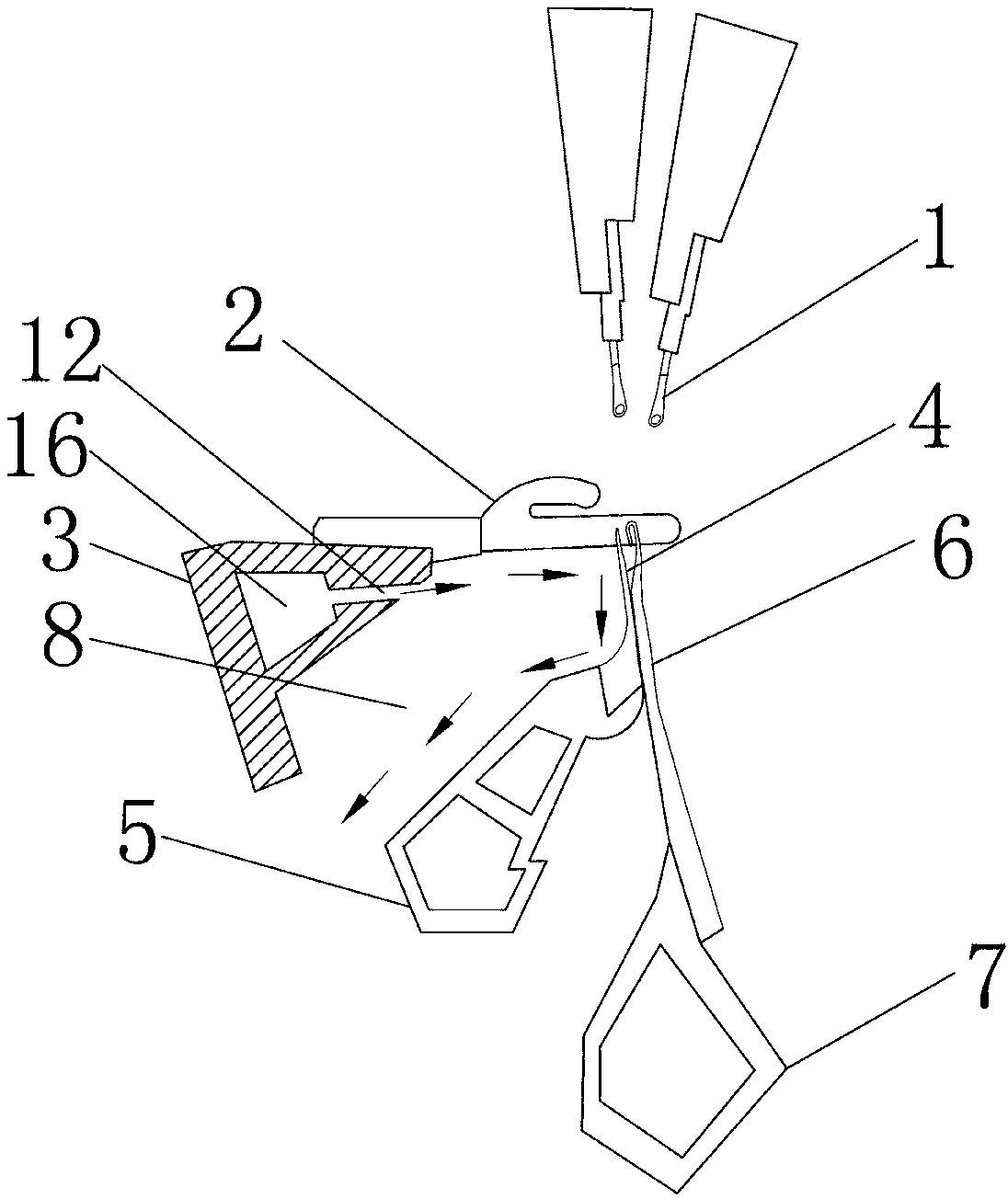

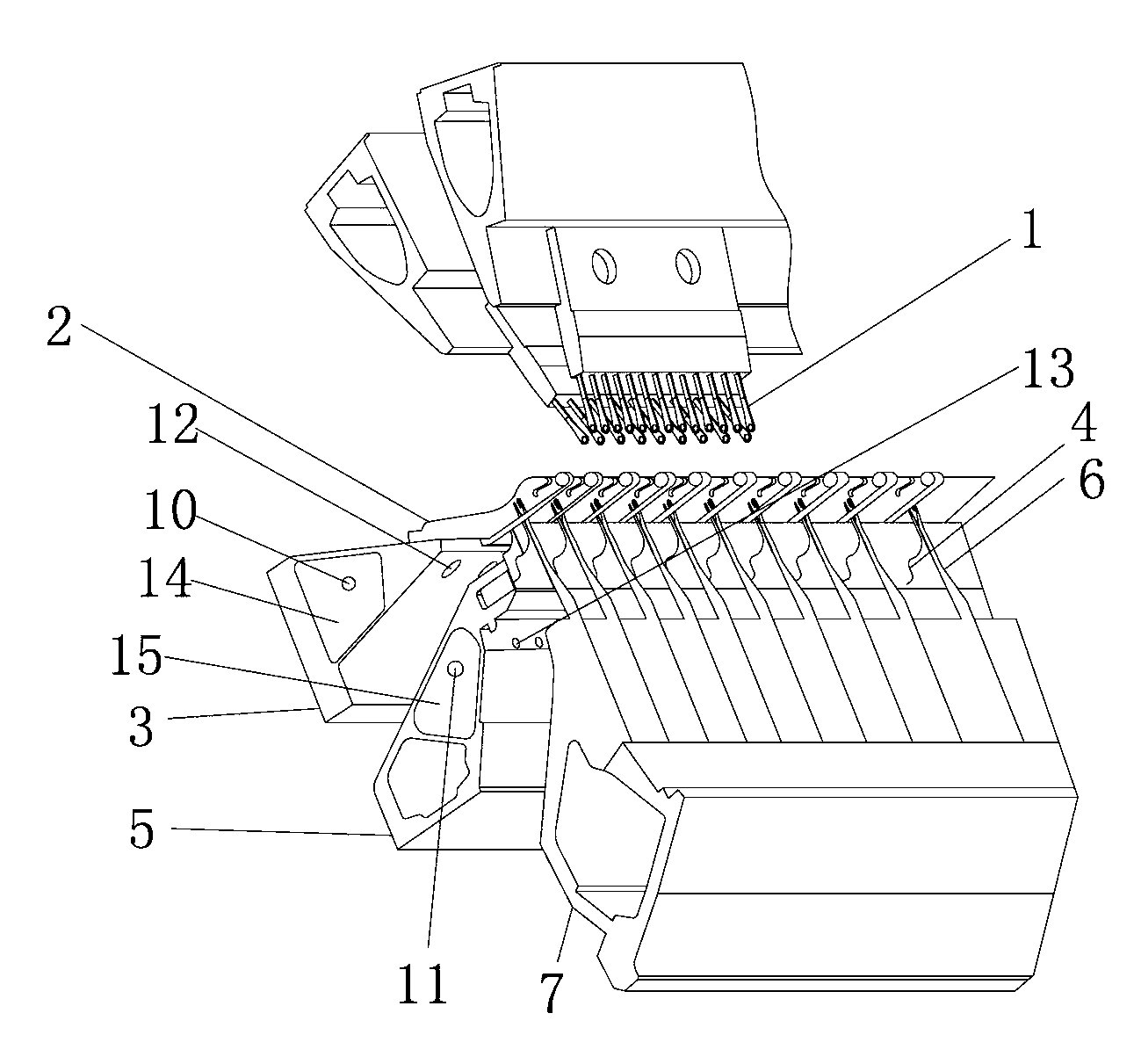

[0014] figure 1 with figure 2 The first embodiment of the present invention is shown: a warp knitting machine with the function of removing hairiness, consisting of guide needle 1, sinker 2 and sinker bed 3, knitting needle 6 and needle bed 7, needle groove 4 and needle The channel A 16 is set on the settled bed 3, the settled bed 3 and the needle channel plate 5 form a semi-enclosed area A 8, the two ends of the channel A 16 are provided with a closing device A 14, and at least one end of the closing device A 14 is provided with a hole A 10 for compressed air to pass through, and several horizontally arranged holes K are evenly distributed along its length direction on the settled bed 3 1 12, Hole K 1 One end of 12 opens into channel A 16 and the other end opens into semi-enclosed area A 8 .

[0015] During the working process of the warp knitting machine, the knitting needles 6 are installed on the needle bed 7 in a row and move together with the needle bed 7. The guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com