Silk fibroin peptide chain-containing AlaGlyAlaGly polyurethane fiber film and preparation method thereof

A polyurethane fiber and silk fibroin peptide chain technology, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of aggregated structure characterization, and achieve the effect that is conducive to processing and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

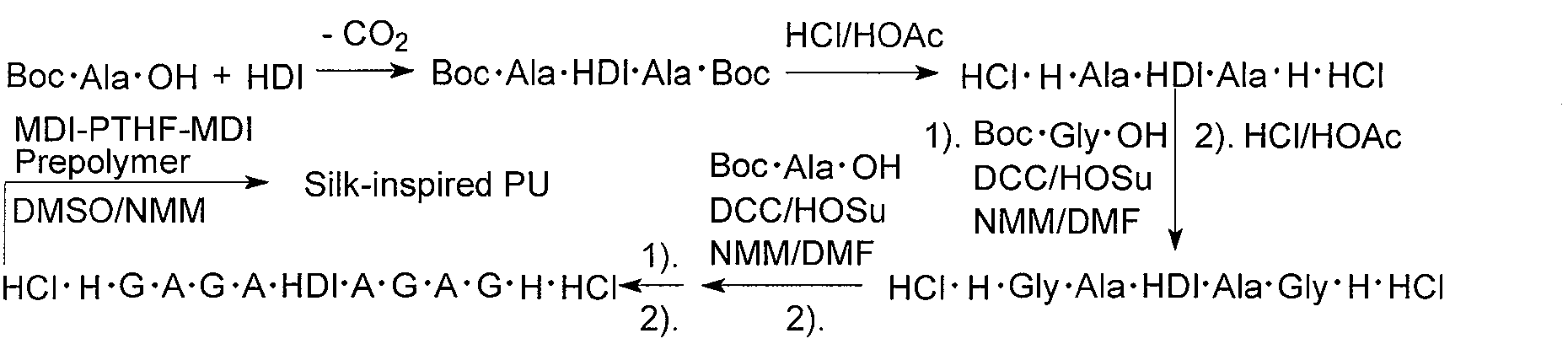

[0025] refer to figure 1 The general route of the polyurethane synthesis process containing silk fibroin peptide chain AlaGlyAlaGly shown is to prepare a polyurethane fiber membrane containing silk fibroin peptide chain AlaGlyAlaGly, including the synthesis and processing of the following steps:

[0026] (1) Synthesis of Boc-Ala-OH+HDI→Boc-Ala-HDI-Ala-Boc

[0027] Pour 100ml of chloroform into a 250ml four-neck flask equipped with a magnetic stirring rotor, then add Boc-alanine (22.70g, 120mmol) and N-methylmorpholine (2ml, as a catalyst), and stir continuously to fully dissolve. Under a nitrogen atmosphere, 30 ml of chloroform in which hexamethylene diisocyanate (10.09 g, 60 mmol) was dissolved was slowly added over 10 minutes. Then the mixture was continuously stirred and reacted at 30°C for 4h, and then continuously refluxed for 14h. After the reaction, when the flask was cooled to room temperature, the reaction solution was washed twice with 10% citric acid aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com