Rotary hot-melting drill bit

A technology of hot-melt drill bits and drill bits, which is applied in the direction of drill bits, thermal energy drilling, drilling equipment, etc., can solve the problems of hot-melt directional drilling tools that have not been introduced, and achieve good compatibility, reduce costs, and increase service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

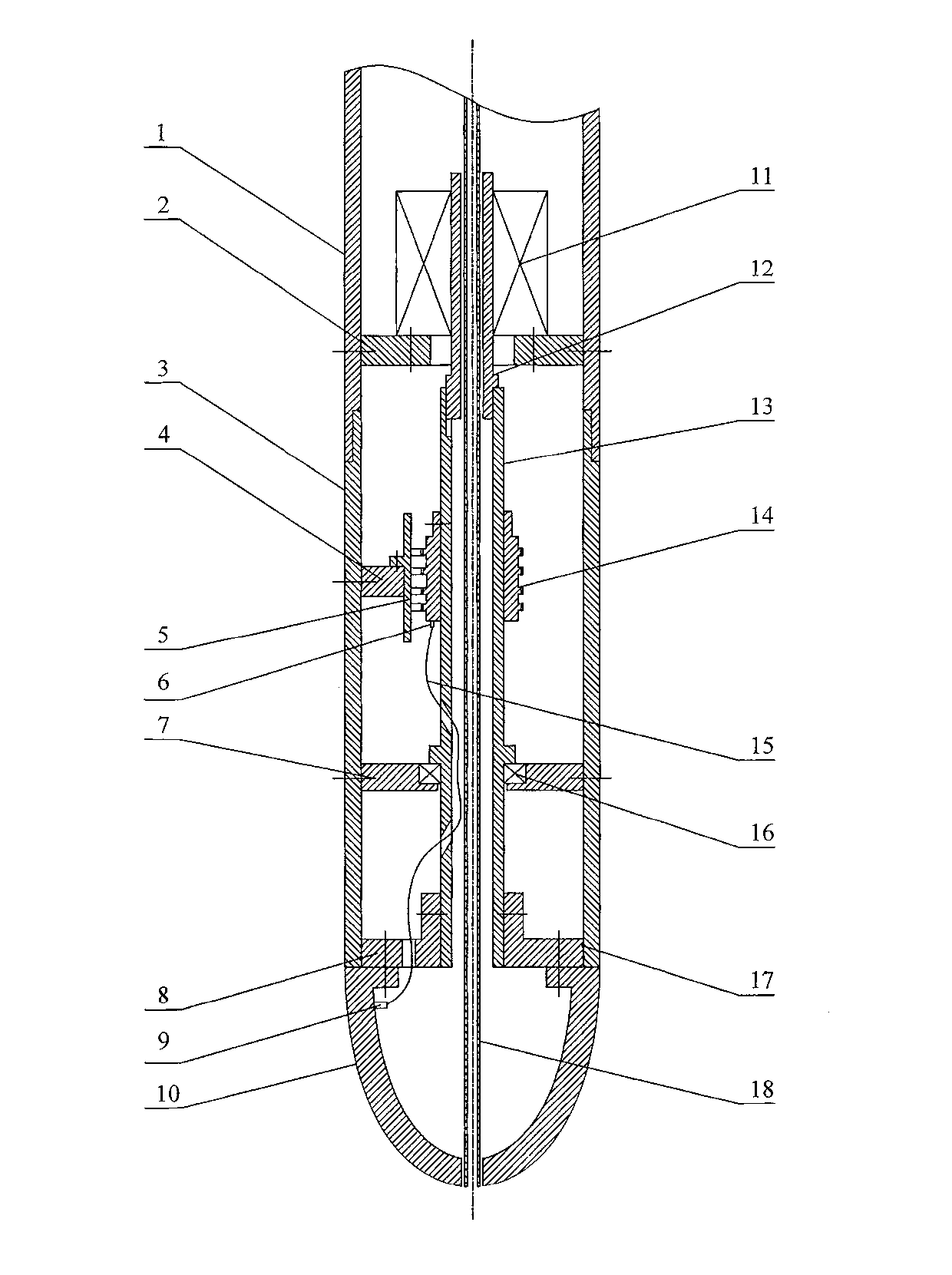

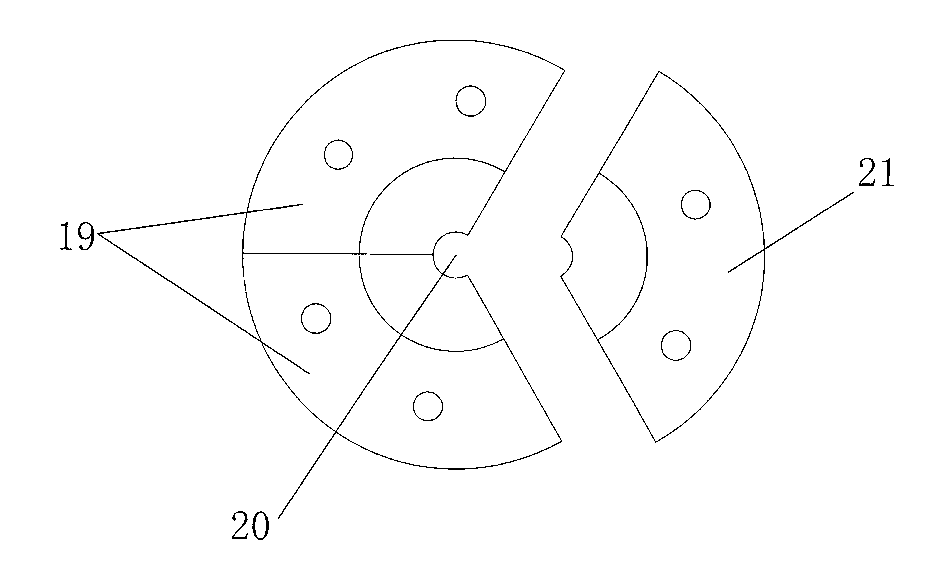

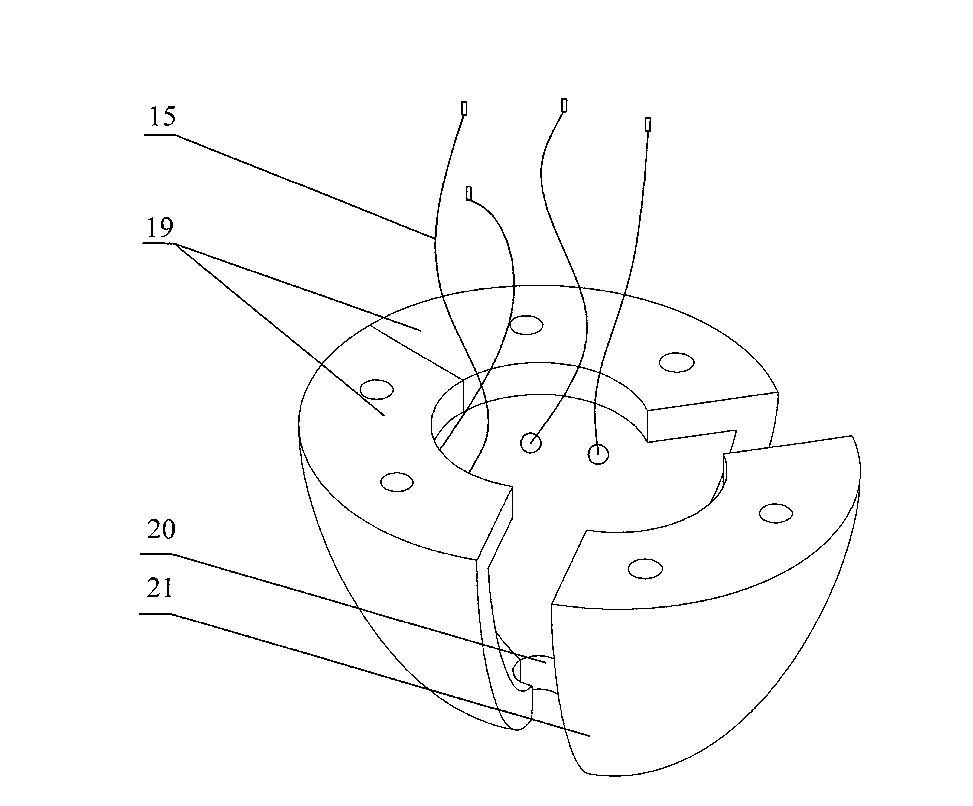

[0015] see figure 1 figure 2 and image 3 As shown, the present embodiment is composed of two independent heating modules 19 and one non-heating module 21, two independent heating modules 19 and one non-heating module 21 form a round head-shaped drill 10, and the bottom of the drill 10 is provided with drainage Port 20, the water suction pipe 18 of the upper drilling tool drainage pump can be installed near the water port 20, the drain port 20 can drain the molten water at the bottom of the hole in time, which is conducive to heat transfer, the heating module 19 is a cast copper heater, and the heating module 19 The side and inner surface of the ice cube are coated with heat-insulating paint, which is conducive to heat transfer through the outer surface to the ice layer.

[0016] The inner wall of the heating module 19 has a wire joint 9, the wire joint 9 is connected to the wire 15, the other end of the wire joint 9 is connected to the slip ring terminal 6, and the wire jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com