Constant current driver of light emitting diode

A light-emitting diode and constant-current driver technology, which is applied in the field of light-emitting diode constant-current drivers, can solve the problems of single-stage PFC circuit power factor reduction, large reference signal error, and large current signal error, so as to reduce input errors and Effect of small current ripple and improved power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

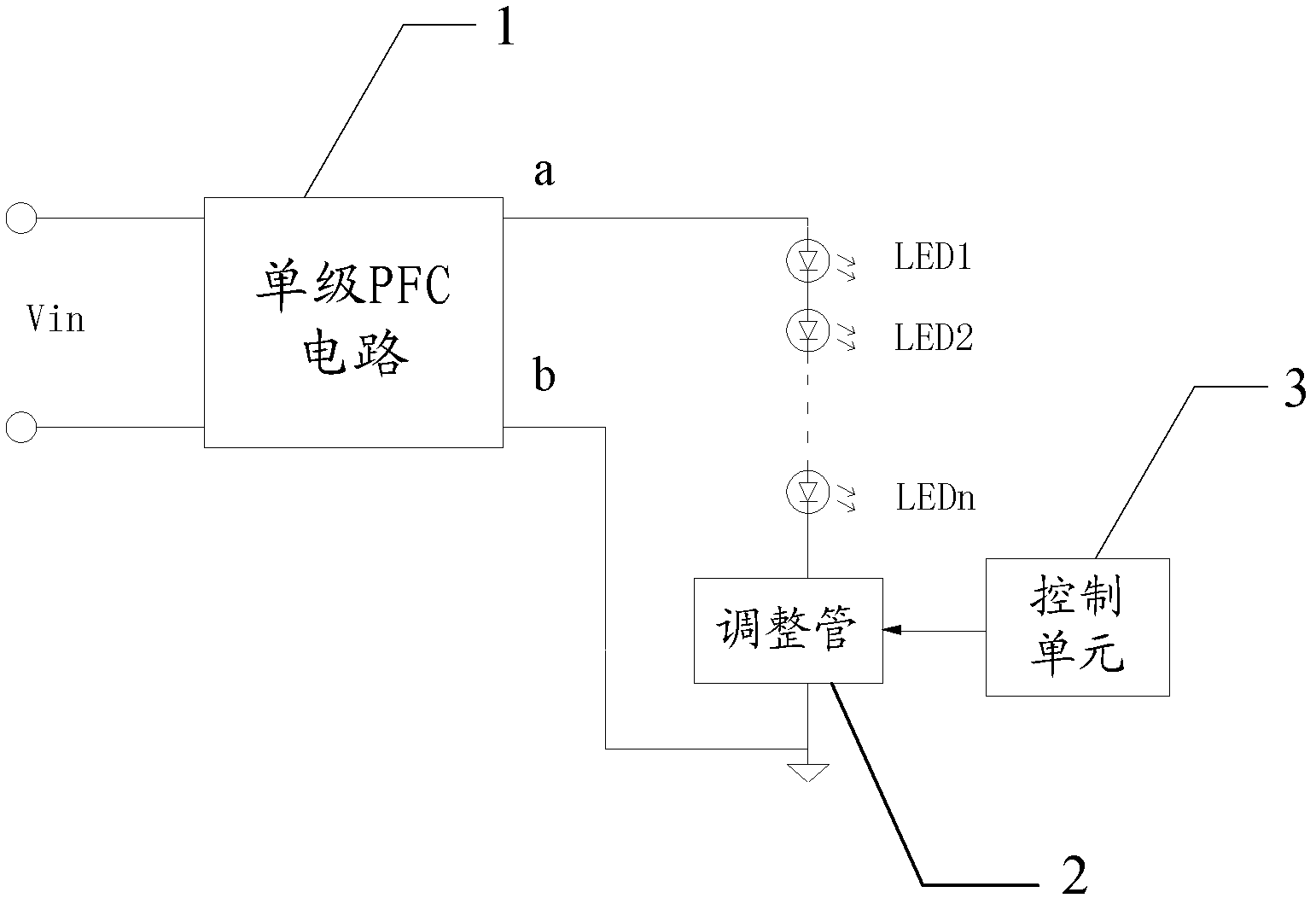

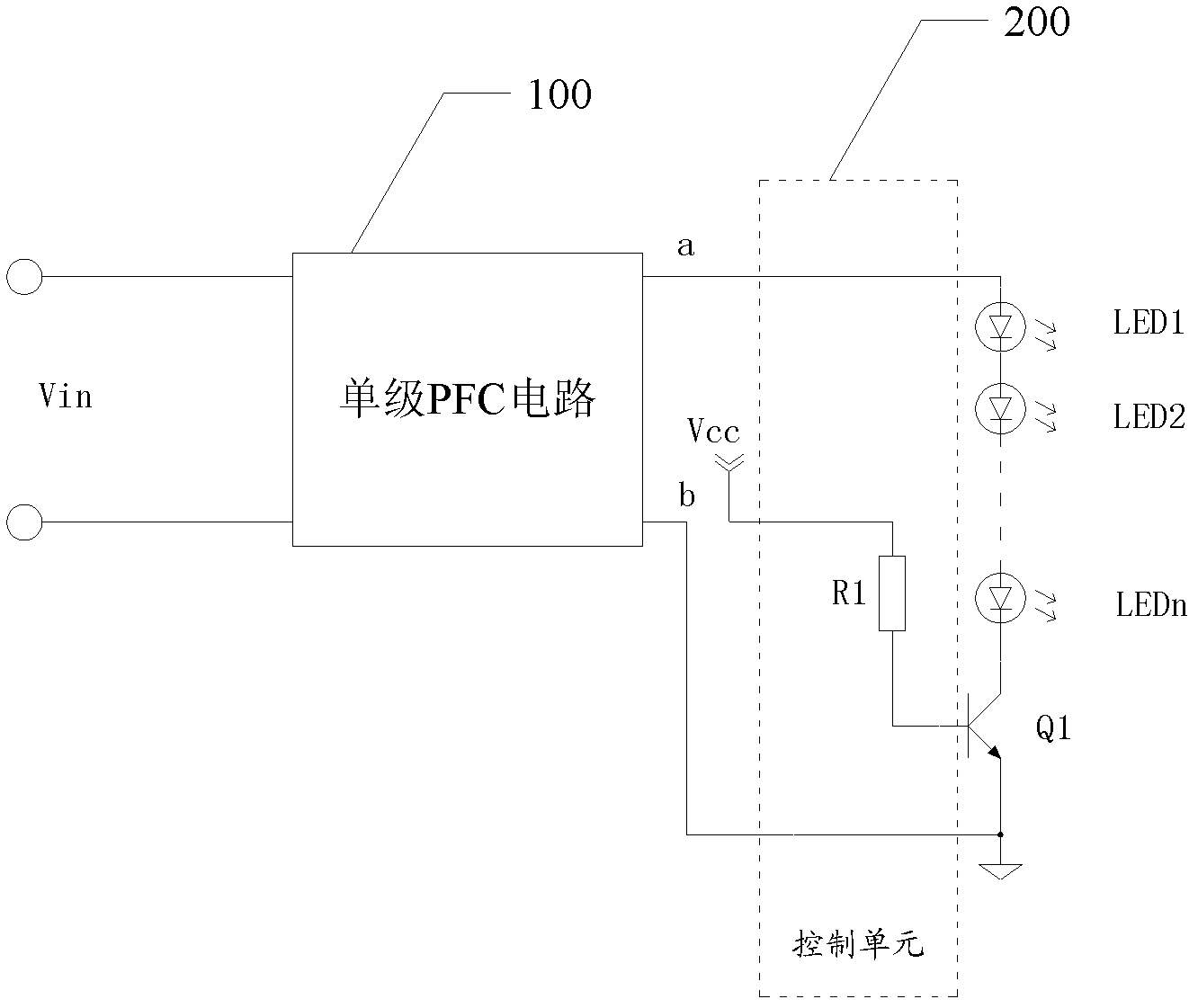

[0031] See figure 2 , Shows a schematic structural diagram of an LED constant current driving device according to an embodiment of the present invention, which mainly includes: a single-stage PFC circuit 1 composed of a single-stage PFC main circuit and a single-stage PFC control circuit, a regulator tube 2 and a control unit 3. among them:

[0032] The input terminal of the single-stage PFC circuit 1 is connected to the power supply Vin, the series branch of the regulator tube 2 and the LED load is connected between the two output terminals of the single-stage PFC circuit, and the control unit 3 is connected to the control terminal of the regulator tube 2 .

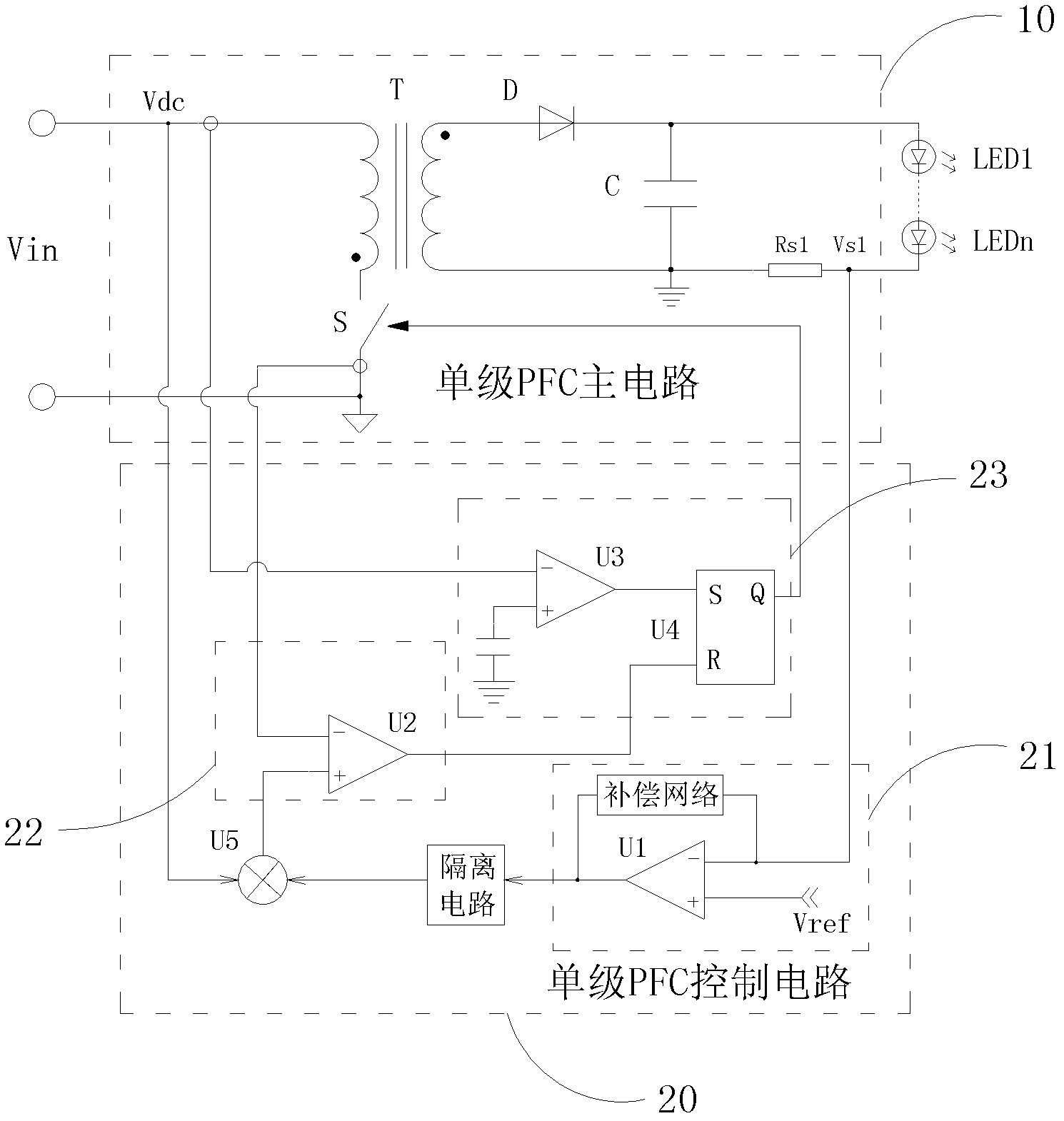

[0033] The single-stage PFC circuit can pass figure 1 The implementation of the circuit s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com