Automatic high-efficiency sugarcane stalk cutting and harvesting machine

A harvester, high-efficiency technology, applied in the direction of harvesters, agricultural machinery and implements, applications, etc., can solve the problems of technical lag, high labor intensity, difficulty in substantive and effective use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

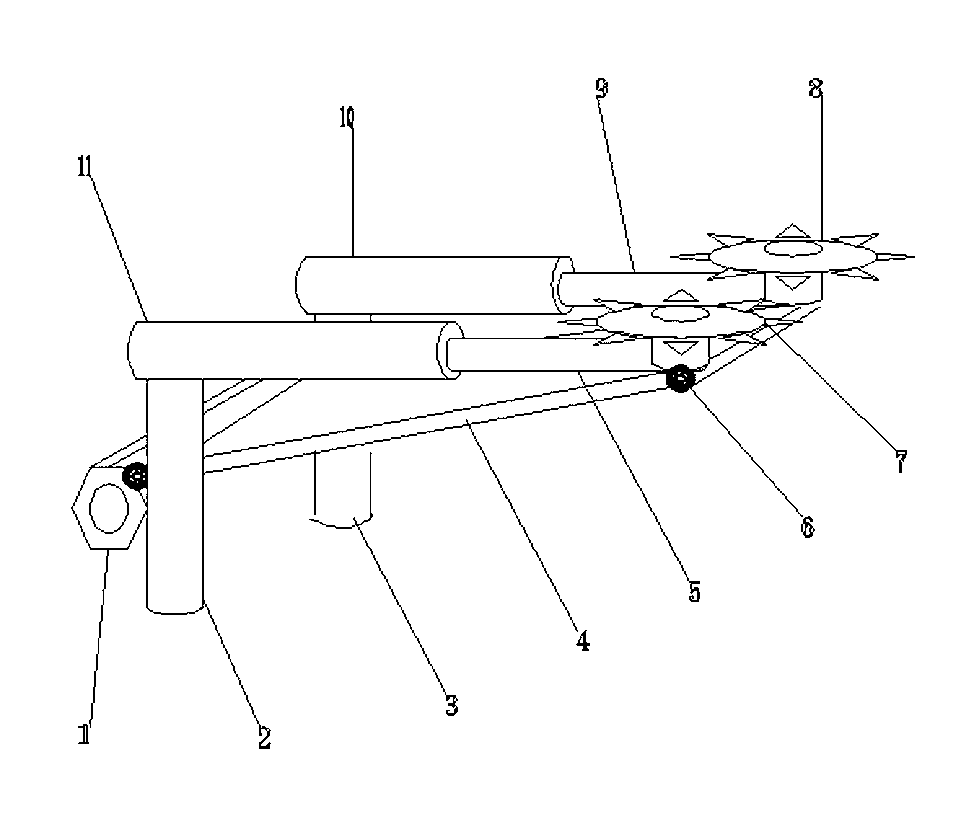

[0016] As shown in the accompanying drawings, the automatic high-efficiency cane stalk cutting and harvesting machine of the present invention includes three parts: a branch body, a driving body and a cutting body.

[0017] Described support body comprises support plate C2, support plate A12, right main plate 14, support plate B15, left main plate 17, and described support plate C2 is arranged on the side away from left main plate 17 and the upper side of secondary cutting wheel F1, and its function is to set The secondary cutting wheel F1 rotating shaft and the left end of the belt conveyor shaft 11, the support plate A12 is arranged on the side away from the right main board 14 and the secondary cutting wheel A10 upper side, and its effect is to set the secondary cutting wheel A10 rotating shaft and the belt conveyor shaft 11 right-hand side, so Described right main board 14 is arranged on away from support plate A12 and support plate B15 and between main cutting wheel A9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com