Method for realizing double-surface asymmetric modification of single-layer graphene

A graphene, asymmetric technology, used in chemical instruments and methods, non-metallic elements, carbon compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

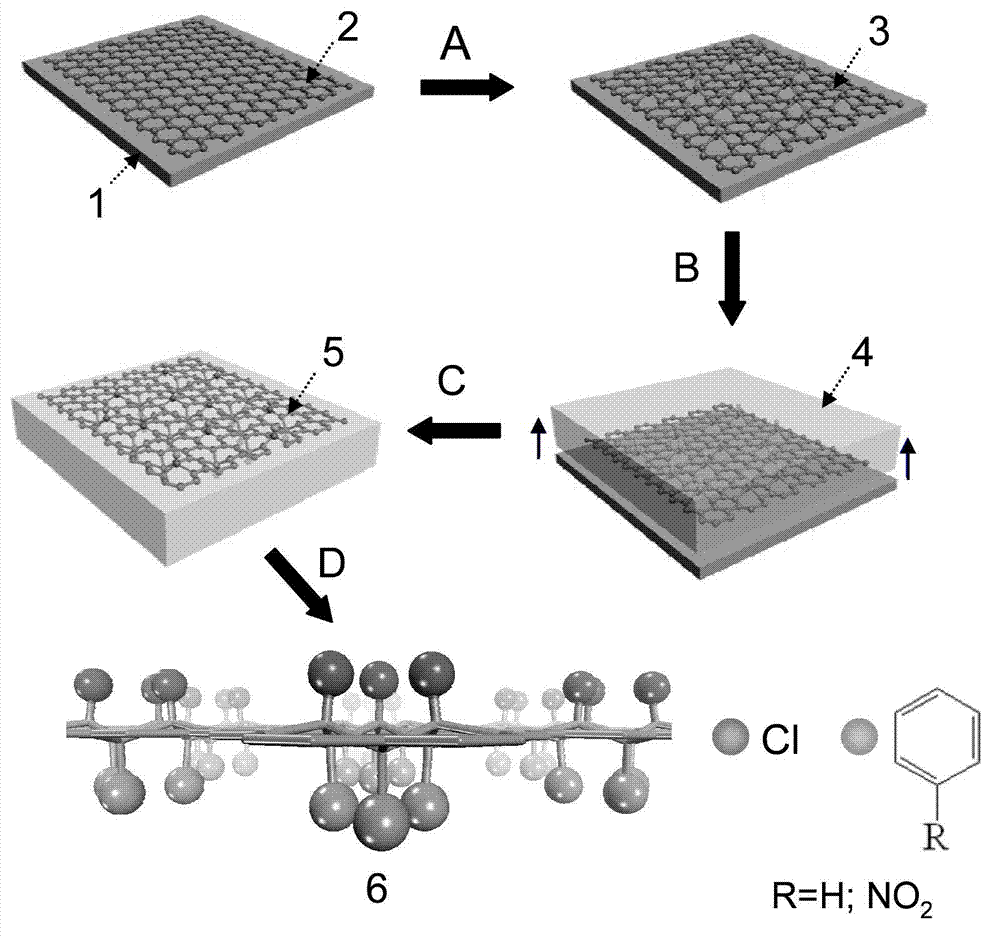

[0035] Example 1. Carrying out double-sided asymmetric covalent modification to single-layer graphene

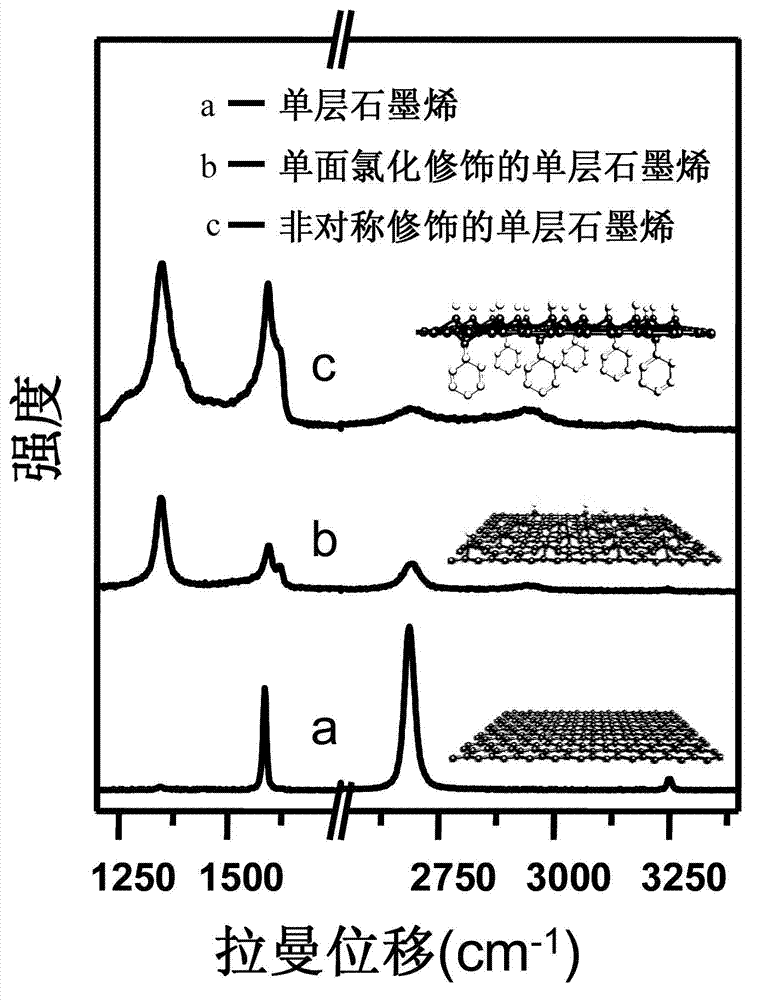

[0036] 1) On Si / SiO 2 Substrate (Si layer thickness is 600μm, SiO 2 The substrate layer is 300nm) and the surface adopts the mode of mechanical exfoliation to prepare single-layer graphene, wherein figure 2 (a) is the Raman spectrum of single-layer graphene on the substrate surface.

[0037] 2) The photochlorination reaction is carried out on the surface of single-layer graphene, and the single-sided chlorination modification of graphene is realized under the protection of the substrate. The specific implementation steps are:

[0038] Using dilute hydrochloric acid (9mol / L) and manganese dioxide powder (5g) to react at 60°C to produce chlorine gas, using nitrogen as a carrier gas to feed the newly produced chlorine gas into the photochemical reaction system of graphene, under the irradiation of ultraviolet light, chlorine gas The decomposition produces chlorine radicals...

Embodiment 2

[0044] Example 2, Carrying out double-sided asymmetric covalent modification to single-layer graphene

[0045] 1) Chemical vapor deposition growth is carried out on the surface of copper foil, so that single-layer graphene is precipitated on the copper surface, and the graphene is transferred to another Si / SiO 2 on the substrate. Wherein, the annealing temperature is 1000° C., the growth environment is a low pressure environment (500 mTorr), the carbon source is methane, and the growth atmosphere is methane 35 sccm / hydrogen 2 sccm.

[0046] 2)-3) steps are the same as in Example 1.

[0047] 4) Using the PMMA film as a protective substrate, carry out nitrophenylation modification on the other side of the chlorination-modified graphene to obtain double-sided asymmetric covalently modified single-layer graphene. The specific implementation steps are:

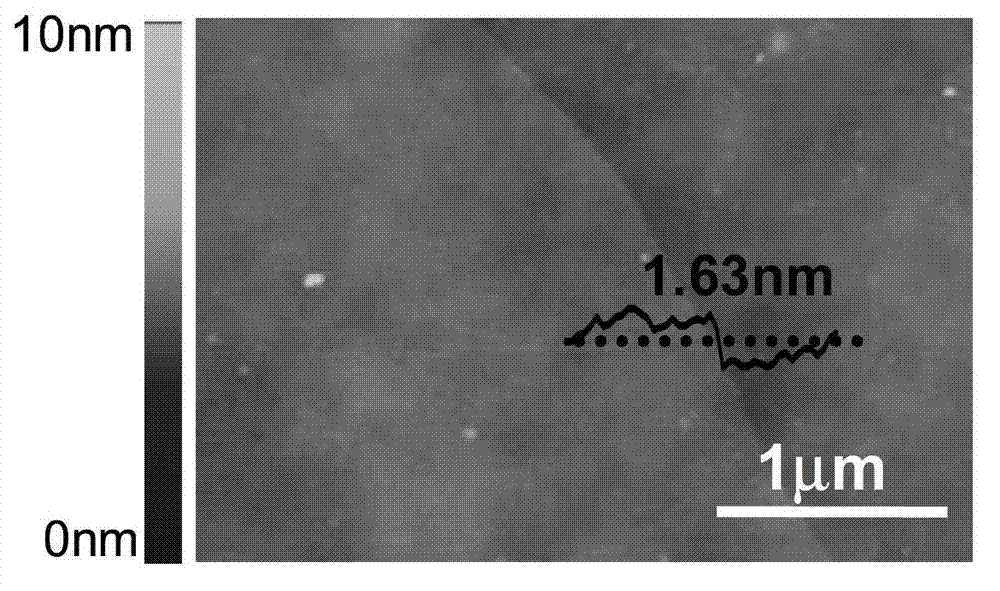

[0048] The sample is placed in a p-nitrobenzene diazonium salt solution with a concentration of 20mmol / L, the temperature is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com