STD type technology and system for recovering condensate water of coal moisture control

A humidity control technology for condensate water and coal, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc., to meet water quality requirements, inhibit pipeline corrosion, ensure pressure and The effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

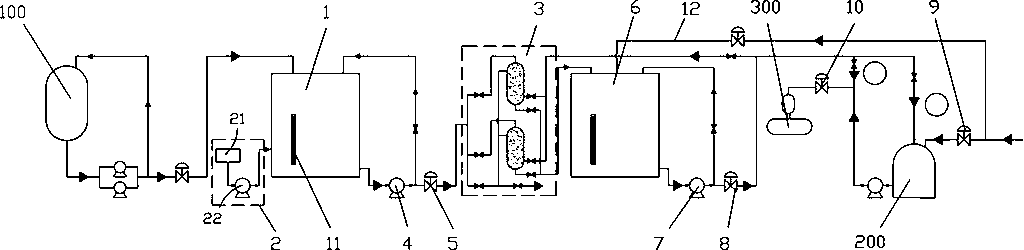

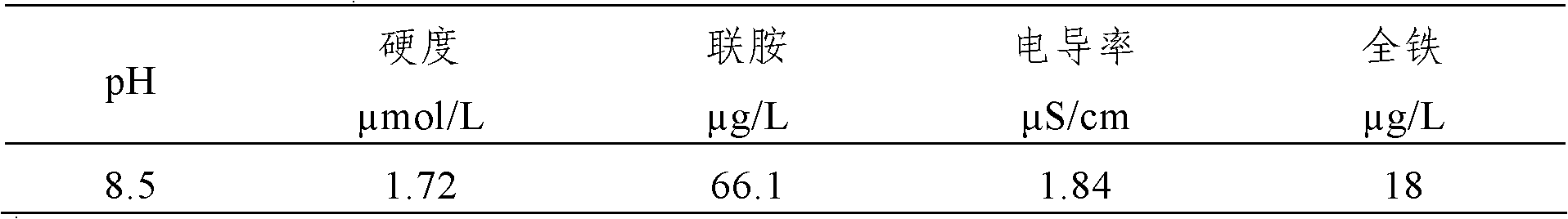

[0041] A STD type coal humidity control condensate recovery process, which comprises the following steps: 1) introducing condensate from the flash tank into a condensate storage tank, adding a treatment agent to the condensate storage tank, the treatment agent comprising ammonia, hydrogen One or more of sodium, hydrazine or sodium phosphate, the pH of the condensed water after reacting with the treatment agent is 8-9.5, the hardness is ≤2 μmol / L, and the hydrazine is 20-100 μg / L; 2) The condensed water after the above reaction Water filtration to remove the total iron in the condensed water and the precipitate produced by the dosing reaction, the total iron content is less than 50 μg / L, and the conductivity is ≤20 μS / cm; 3) The above-mentioned filtered condensed water is introduced into the pure The deaerator in the water tank or CDQ section is recycled; among them, the temperature of the condensed water introduced into the pure water tank needs to be adjusted to make the water...

Embodiment 2

[0051] Condensation point of use: pure water tank;

[0052] Steam consumption: 25t / h;

[0053] Condensate flow: 23.5t / h;

[0054] Condensed water temperature: 54°C;

[0055] Membrane filter device: metal stainless steel sintered wire mesh membrane or polytetrafluoroethylene solid support membrane.

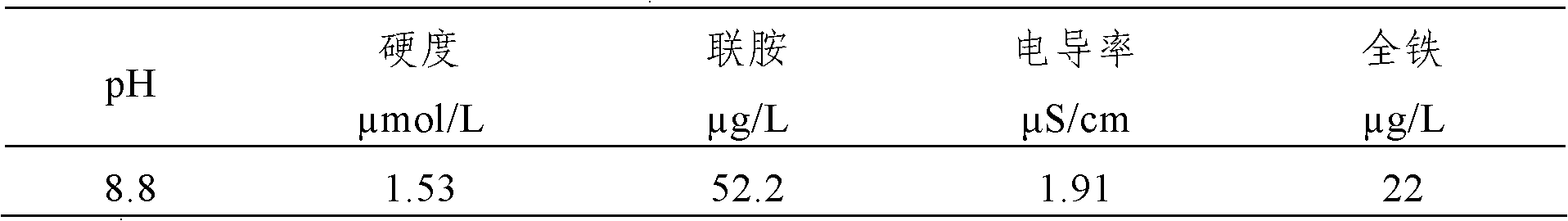

[0056] The water quality of condensate is shown in Table 2:

[0057] Table 2

[0058]

[0059] It can be seen from the above that, by adopting the process of the present invention, the condensed water is effectively recovered, and the remaining heat energy is directly used; the water quantity of the water supply pipeline incorporated into the CDQ is stable, and the temperature of the condensed water meets the requirements, and has no adverse effect on the CDQ operation and production ; The water quality of the condensed water is effectively controlled, which can meet the water requirements of CDQ boilers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com