Electrolytic cell for molten salt electrolysis

A molten salt electrolysis and electrolysis cell technology, applied in electrolysis components, electrolysis process, cells, etc., can solve the problems of reduced output, large electrode spacing, reduced production efficiency, etc., to reduce bubble effect, small electrode spacing, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

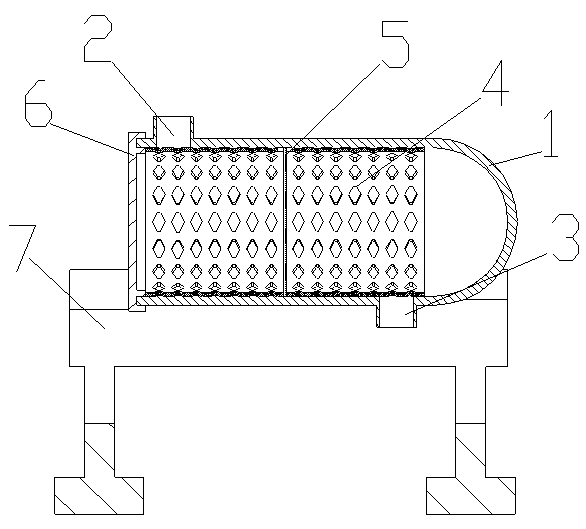

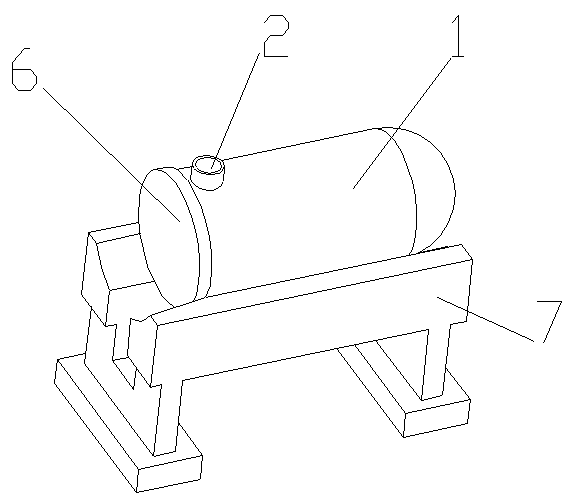

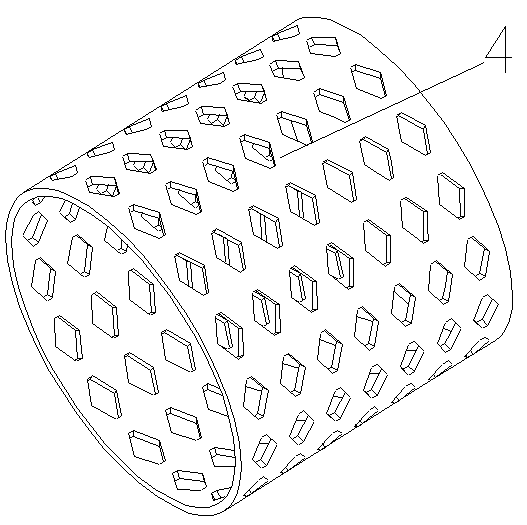

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 , attached figure 2 , attached image 3 The shown electrolytic cell for molten salt electrolysis of the present invention includes a bracket, a cell body placed on the bracket, a sealing cover, a cathode, an anode, and a diaphragm, and is characterized in that: the cell body is a U-shaped column , the two ends of which are respectively provided with a liquid inlet and a liquid outlet; the anode and the cathode are reticulated columns and placed in the tank; the sealing cover is placed at one end of the tank; the diaphragm is arranged in the tank The middle part of the body is placed between the anode and the cathode. The liquid inlet and the liquid outlet are respectively placed at the highest point and the lowest point at both ends of the tank body; the sealing cover plate is connected with the tank body in a concave-convex tight fit; the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com