Roof parapet flashing place structure and construction method thereof

A construction method and parapet technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve the problems of easy cracking at the flooded part of the roof parapet, slow construction speed at the flooded part of the roof parapet, and poor construction efficiency. The process is cumbersome and other issues, to achieve the effect of ensuring the overall facade effect and the quality of the flashing, shortening the total construction period of the project, and shortening the maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

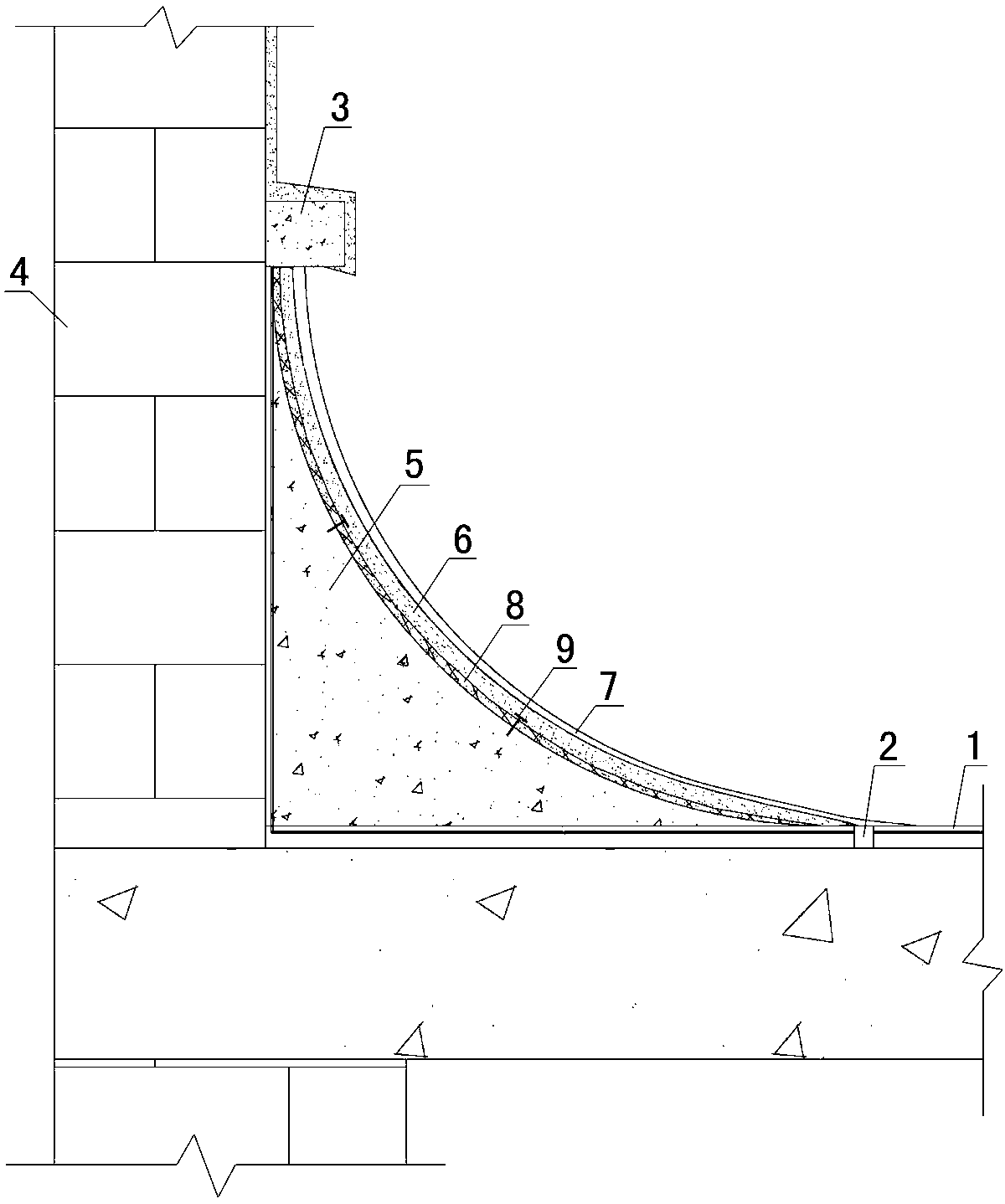

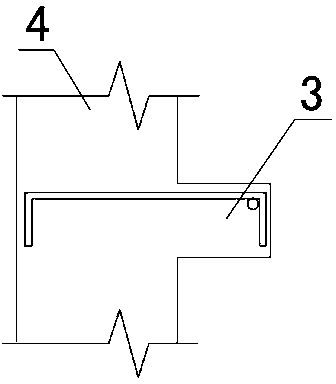

[0021] Examples see figure 1 As shown, this roof parapet flashing structure is arranged below the dripping eaves 3 on the parapet 4, at the junction of the parapet and the roof finish surface. The reinforcement of the dripping eaves 3 can be found in figure 2 .

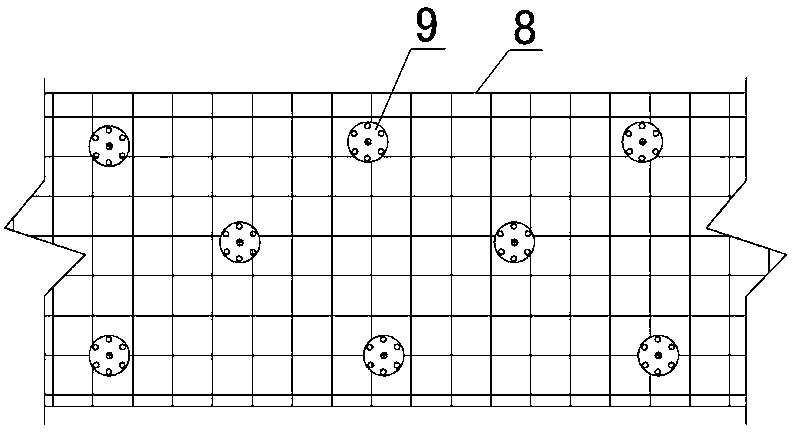

[0022] This kind of roof parapet flashing structure includes a separation joint (set along the periphery of the parapet wall) on the roof finish surface 1 at a distance of 200mm to 300mm from the parapet wall, a sealant 2 embedded in the separation joint, and a sealing paste set on the sealant The C20 fine stone concrete fillet between the parapet and the parapet 5, the galvanized steel wire mesh fixed on the arc surface of the C20 fine stone concrete fillet through the insulation nails 9, and the galvanized steel wire mesh 8 brushed on the galvanized steel wire mesh 8 Mortar layer 6, and one felt and two oils 7 laid on the waterproof mortar layer. In this embodiment, the separation seam is about 250mm away from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com