Marine diesel engine scr reactor diversion device

A technology for SCR reactors and marine diesel engines, which is applied in mufflers, exhaust devices, machines/engines, etc., which can solve the problem that the catalytic capacity is not fully utilized, which affects the application of SCR systems on ships, and the axial size of the expansion cavity is large, etc. problems, to achieve the effect of improving circumferential unevenness, improving radial unevenness, and uniform flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

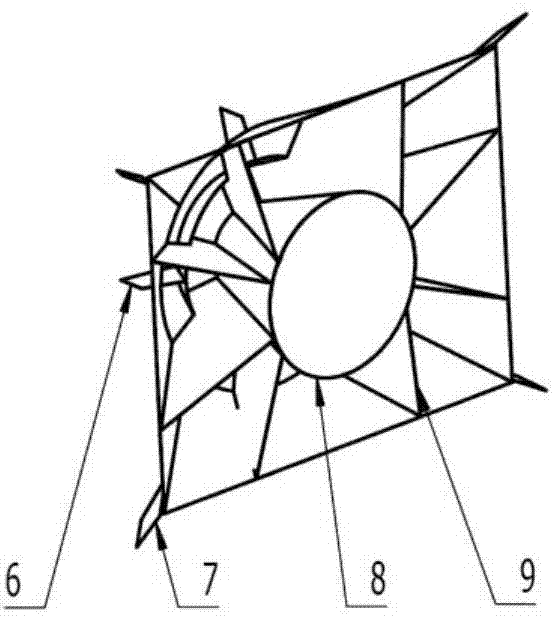

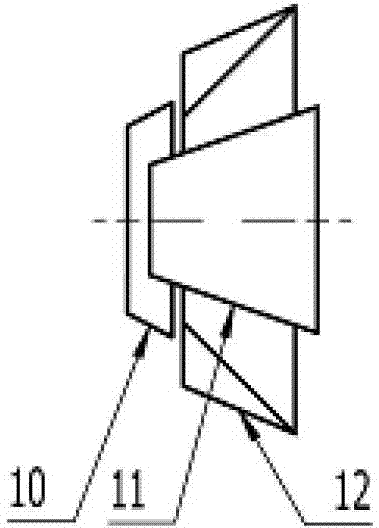

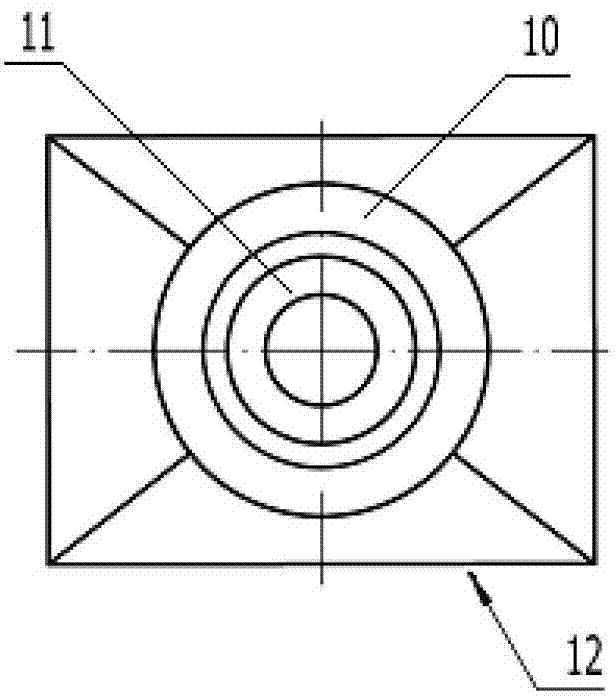

[0017] The invention provides a diversion device for a marine diesel engine SCR reactor, as attached figure 1 As shown, it includes guide ring 8, guide plate 9, front support plate 6 and rear support plate 7, as attached Figure 6 The peripheral device shown is a diesel engine SCR reactor. The dimensions of the diesel engine SCR reactor are 1854mm×1675mm×2924mm. The inlet of the expansion chamber 3 of the diesel engine SCR reactor is connected to the circular chamber 1 of Φ600mm, and the outlet is connected to the square chamber 4 of 1500mm×1140mm. The catalyst 5 is built in the square cavity, and the expansion ratio of the expansion cavity 3 is 6. If a small expansion angle is used, the length of the expansion cavity will exceed 1000mm. Due to actual needs, the length of the expansion cavity 3 is required to be controlled at about 400mm, and the expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com