Eight-stroke large-power energy-saving micro-discharge engine master device

A technology with huge power and low emission, which is applied in the field of main parts of eight-stroke high-power, energy-saving and micro-emission engines, can solve the problems of rare eight-stroke engines, and achieve the effects of low cost, stable performance and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

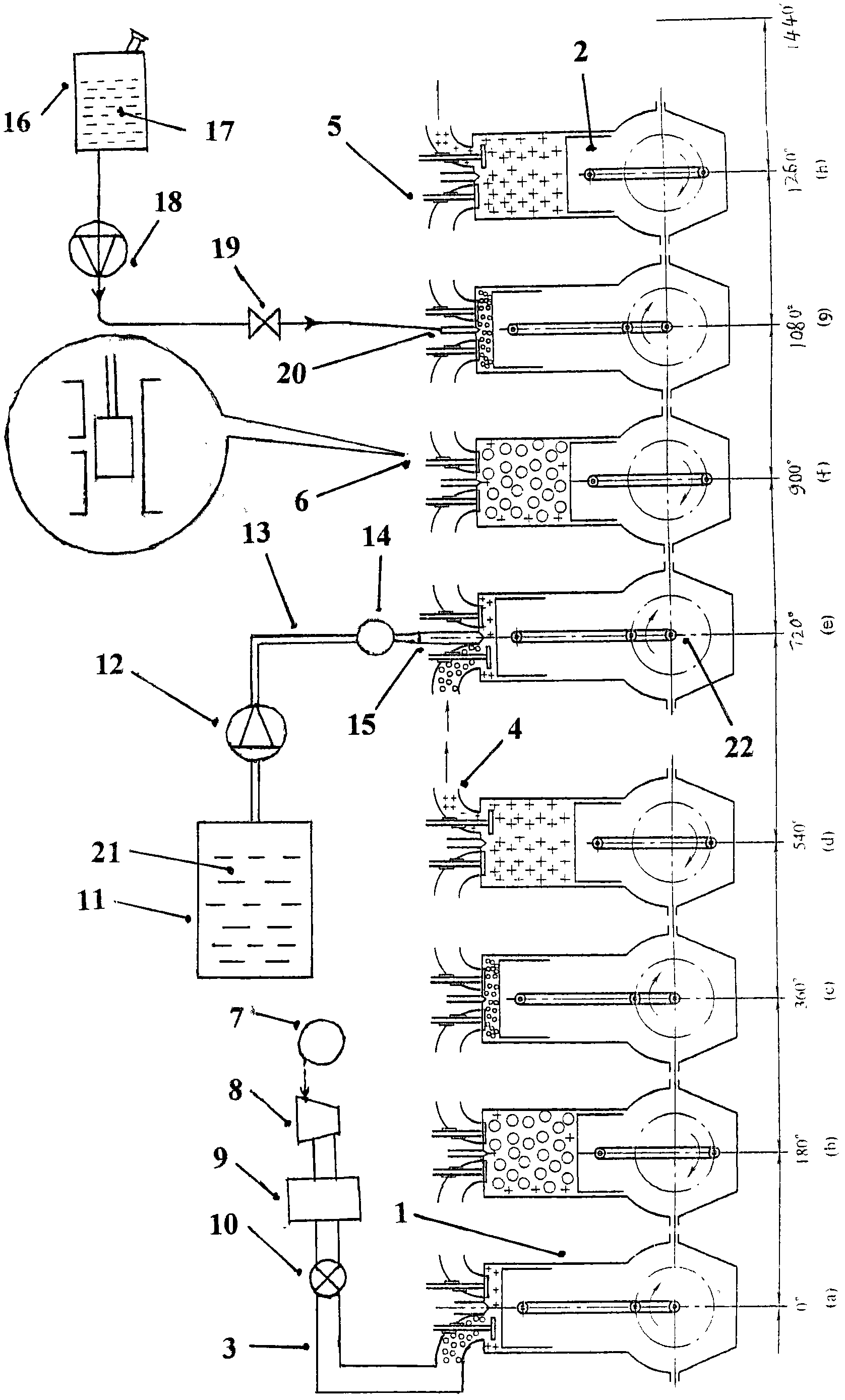

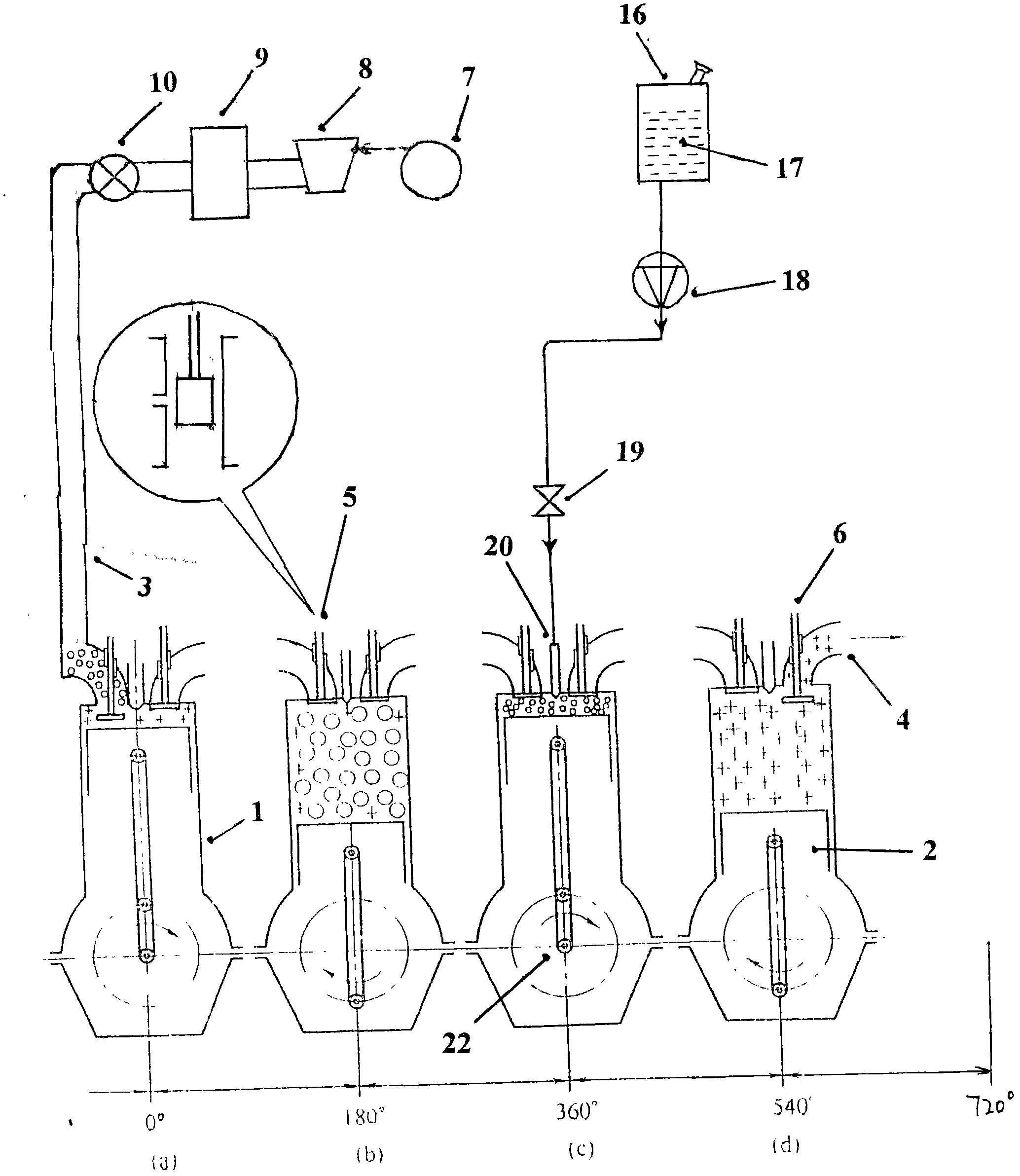

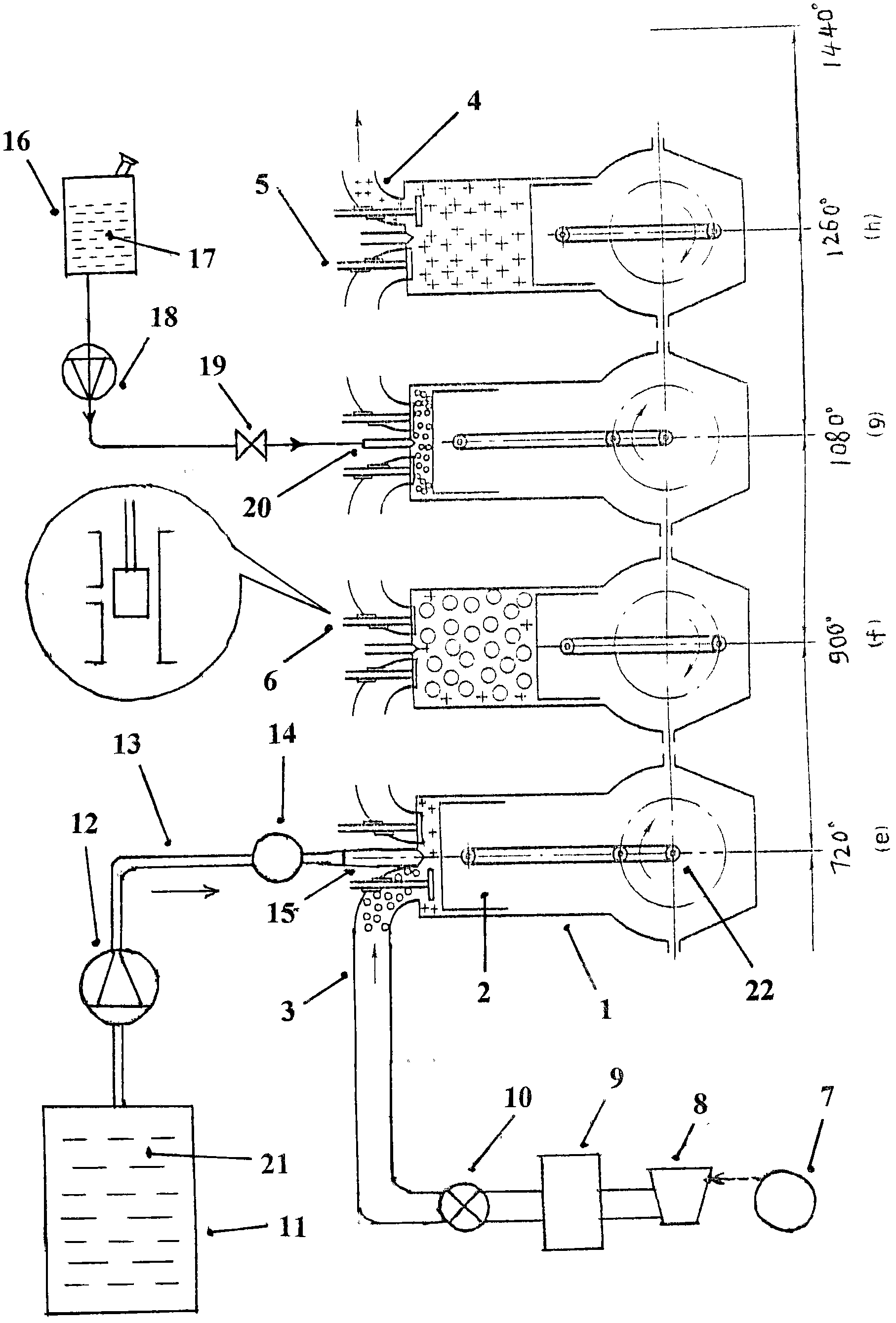

[0012] exist figure 1 Among them, a piston (2) is set on the cylinder (1), a shutter-type piston intake valve (5) is set on the upper air inlet (3) of the cylinder (1), and a shutter-type piston intake valve (5) is set on the exhaust airway (4). Piston exhaust valve (6). An oxygen-enriched air generator (7), a pressure pump (8), an air storage tank (9), a pressure oxygen-enriched air input controller (10) are set on the air inlet (3), and one end of the pressure pump (8) is connected to the The other end of the oxygen-enriched air generator (7) is connected to the air storage tank (9), and one end of the pressure oxygen-enriched air input controller (10) is connected to the air storage tank (9) and the other end is connected to the air inlet (3) . The upper cylinder head of the cylinder (1) is provided with a non-flammable water-alcohol mixture tank (11), a high-pressure pump (12), a high-pressure pipe (13), a water-alcohol mixture high-pressure input controller (14), a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com