Minitype heavy-current PCB (Printed Circuit Board) automobile relay

An automotive relay, high-current technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of poor lead-out solderability, large volume lead-out, and unsatisfactory positioning, reducing the number of parts and volume. The effect of small, high load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

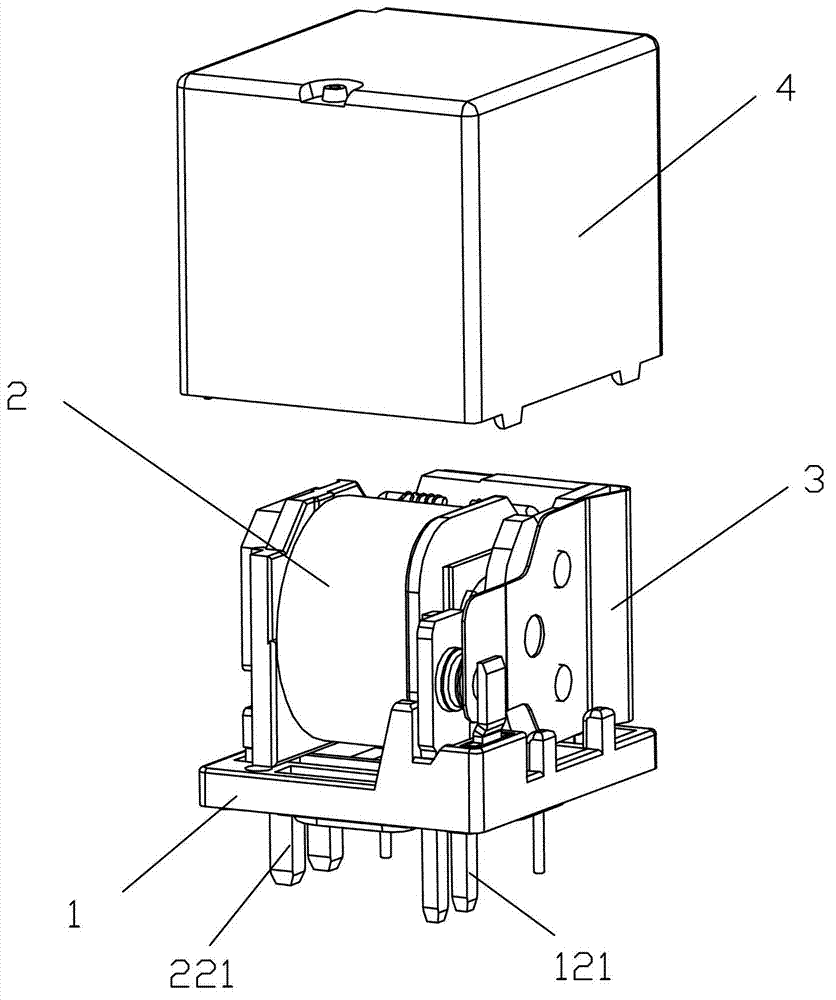

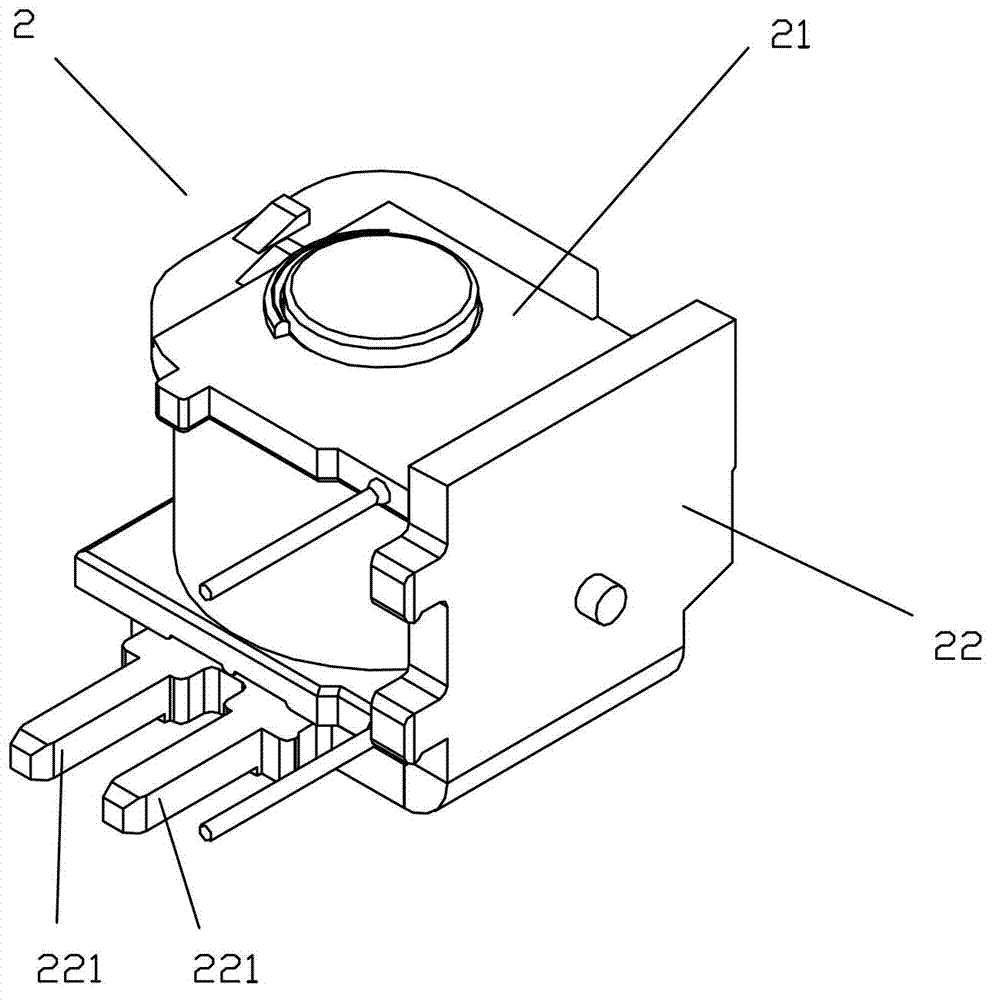

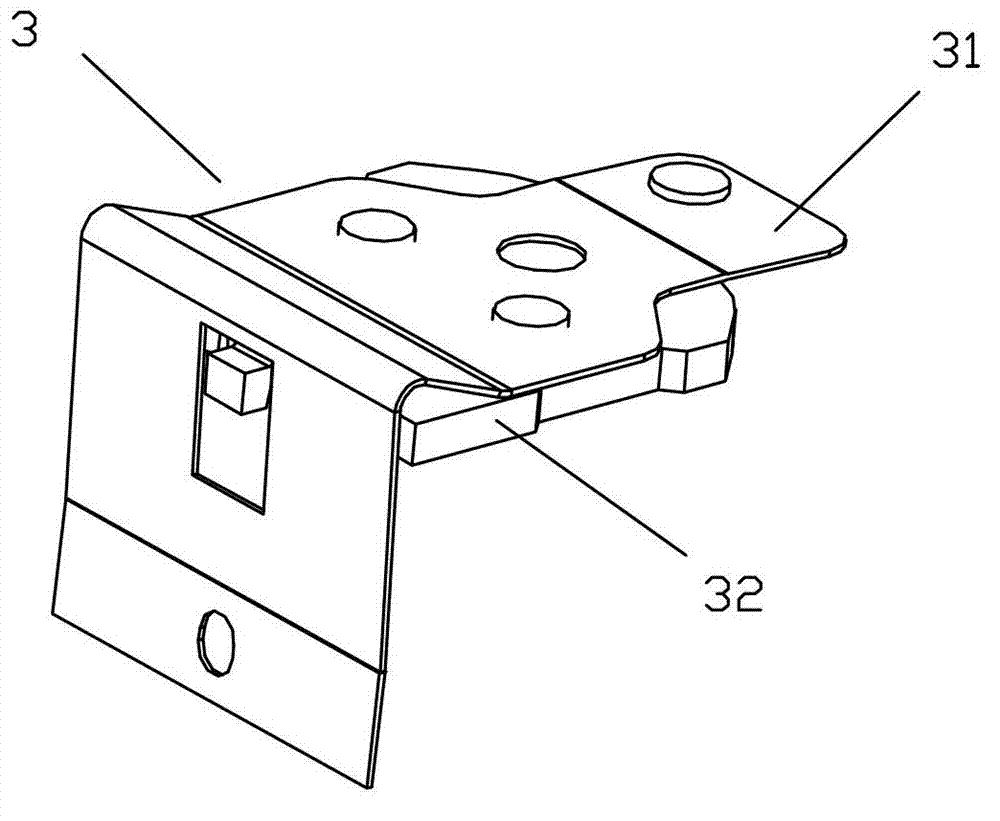

[0029] Examples, see figure 1 As shown in Figure 5, a small-sized high-current PCB automotive relay of the present invention includes a base part 1, a magnetic circuit part 2, a moving spring armature part 3 and a housing 4; the base part 1 includes a base 11 and a static spring fixed on the base 12 and positioning piece 13, static spring 12 is provided with static spring lead pin 121; Magnetic circuit part 2 comprises coil part 21 and the yoke iron 22 that is fixed with coil part, and wherein coil part 21 comprises iron core, bobbin, enameled wire and Coil lead-out pin; moving spring armature part 3 comprises moving reed 31 and armature 32 fixed with moving reed; moving spring armature part 3 is fixed with yoke 22 by moving reed 31 so that armature 32 is in and coil part 21 corresponds to the matching position, that is, the armature 32 can attract the iron core when the coil is energized; on the yoke 22 of the magnetic circuit part, there is a yoke lead-out foot 221 extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com