Manufacture method for active layer of carbon nano tube field effect transistor

A field effect transistor and carbon nanotube technology, which is applied in the fields of nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve the problems of extremely demanding physical and chemical properties of ink, easy aggregation of carbon nanotubes, and high cost of printing equipment , to achieve the effect of good transmission characteristics, low cost, and simplified production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

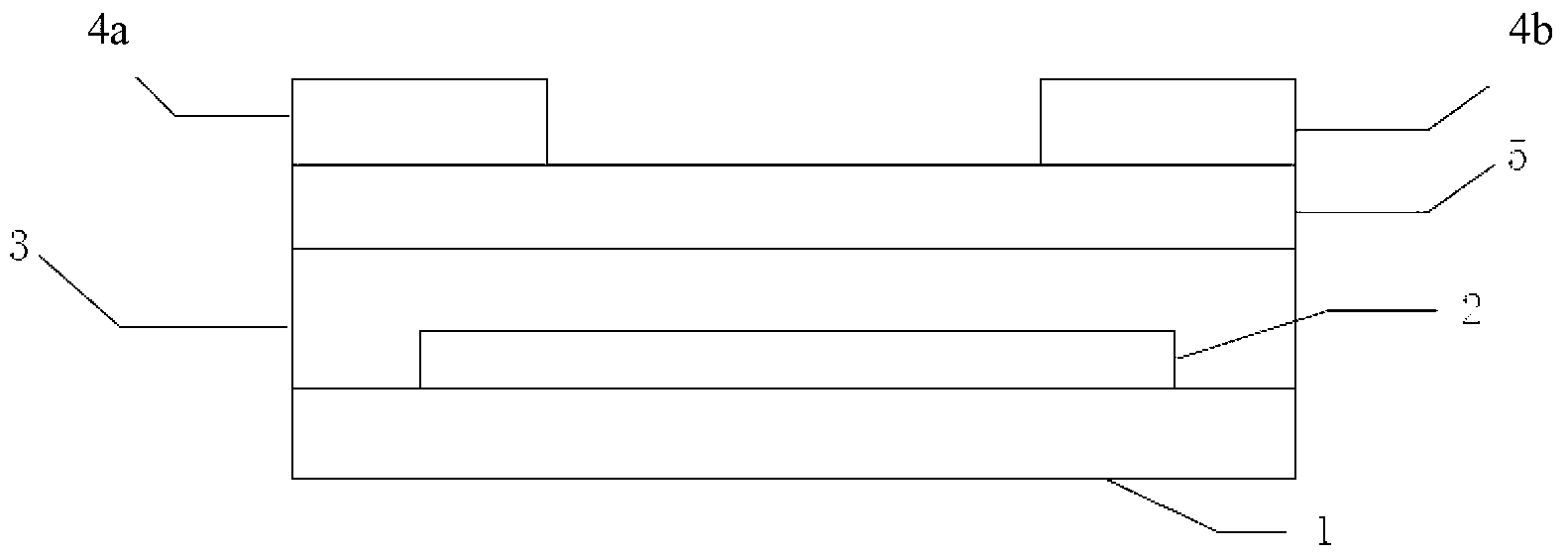

[0024] In this embodiment, a bottom gate-top contact type carbon nanotube field effect transistor is taken as an example. Such as figure 1 As shown, the carbon nanotube field-effect transistor is composed of substrate 1, gate 2, insulating layer 3, active layer 5, source 4a, and drain 4b from bottom to top. Wherein, the preparation method of the active layer 5 is as follows:

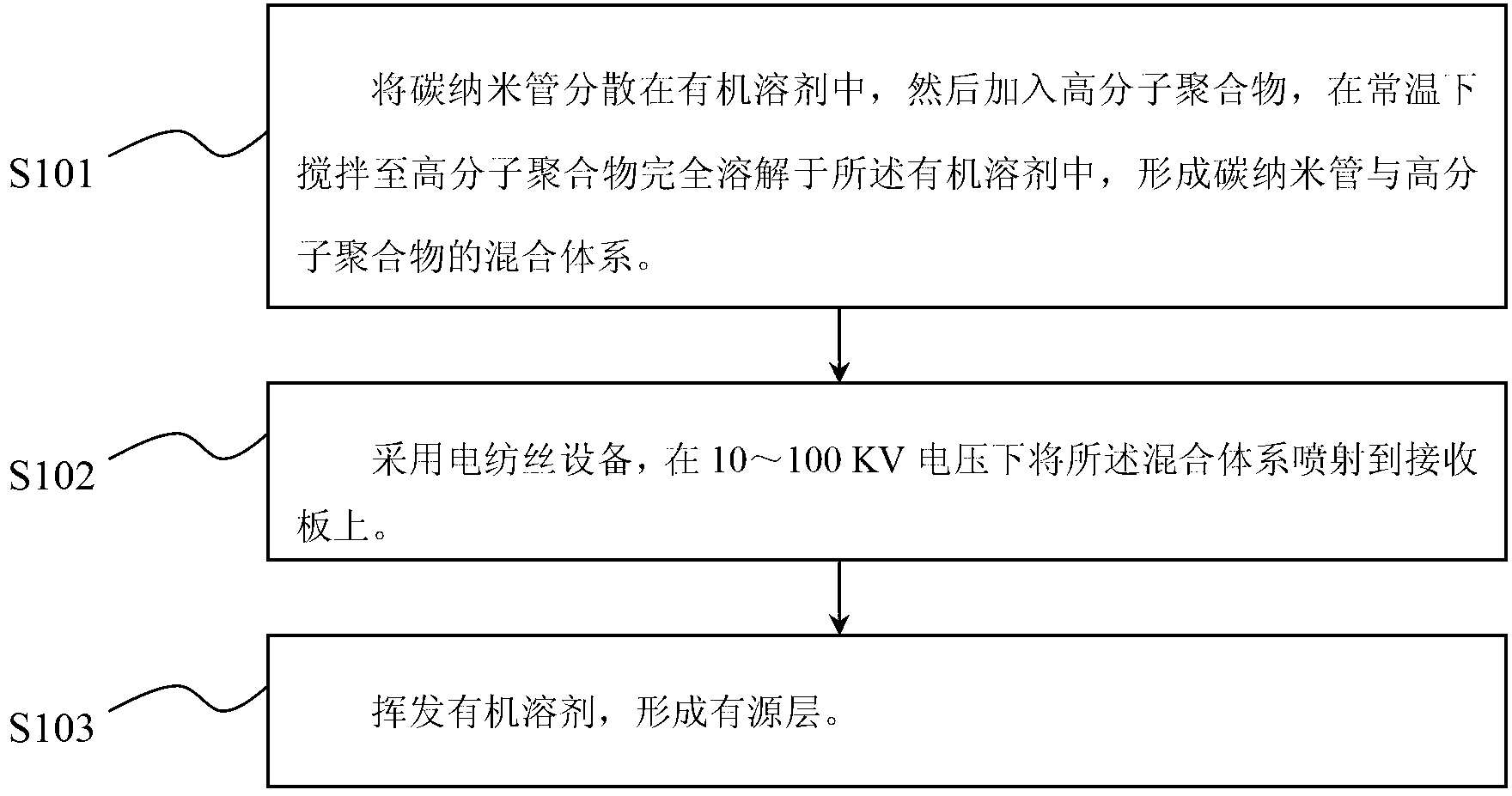

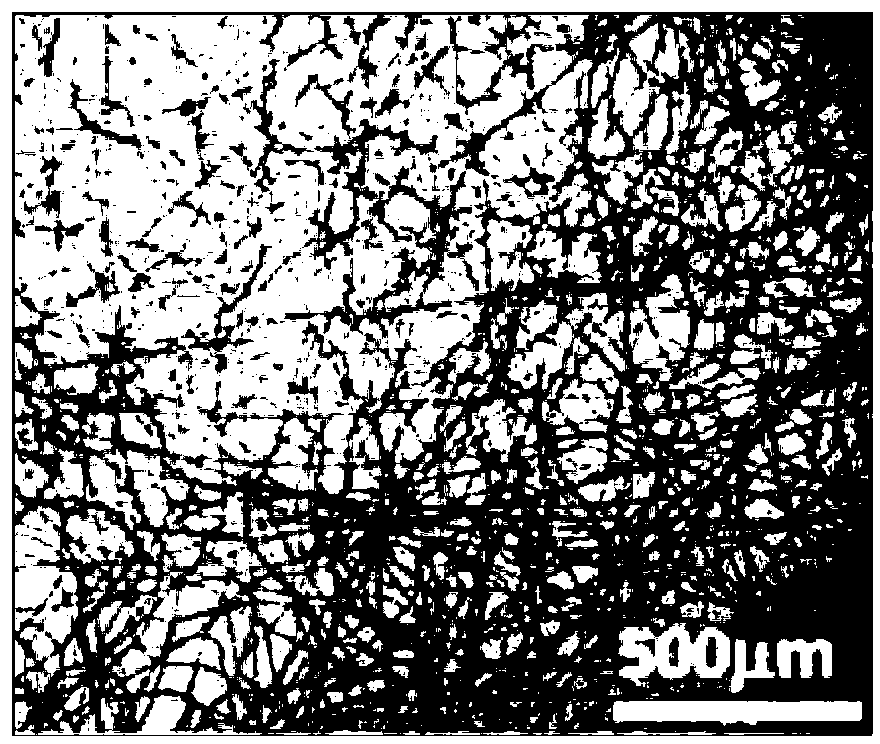

[0025] In this embodiment, carbon nanotubes (hereinafter referred to as CNT) are used as raw materials, chloroform is used as an organic solvent, and the high molecular polymer is polyacrylonitrile. Combine figure 2 Steps S101 to S103 in step S101, the manufacturing process of the active layer in this embodiment: First, CNTs are dispersed in chloroform by vigorous stirring for 2h, and then polyacrylonitrile is added in a ratio of 1:1 to the mass ratio of CNTs. Stir with a magnetic stirrer for 0.5 h at °C until the polyacrylonitrile is completely dissolved in the chloroform to form a CNT and polyacrylonitr...

Embodiment 2

[0031] In this embodiment, a top gate-top contact type CNT field effect transistor is fabricated, such as Figure 4 Shown. The CNT field effect crystal structure of this embodiment is: from bottom to top, the substrate 1, the active layer 5, the source 4a and the drain 4b, the insulating layer 3, and the gate 2 in order.

[0032] Wherein, in the manufacturing steps of the active layer 5 in this embodiment, the high molecular polymer adopts polyvinyl alcohol, and the mass ratio of CNT to CNT is 1:4, and the mass concentration after being dissolved in ethanol to form a mixed system is 10wt%. Then, through a spinneret with an inner diameter of 5 mm, a voltage of 100 KV was applied, and the mixed system was sprayed onto a receiving plate (ie, substrate 1) 30 cm from the nozzle of the spinneret. For the remaining steps of the method for preparing the active layer 5, reference may be made to Embodiment 1. Further, the substrate 1 of this embodiment is ceramic, and the source electrode...

Embodiment 3

[0034] In this embodiment, a top gate-bottom contact type CNT field effect transistor is fabricated, such as Figure 5 Shown. The CNT field effect crystal structure of this embodiment is: from bottom to top, the substrate 1, the source 4a and the drain 4b, the active layer 5, the insulating layer 3, and the gate 2 in order.

[0035] Wherein, in the manufacturing steps of the active layer 5 in this embodiment, the high molecular polymer is polystyrene, and the mass ratio of the CNT is 1:10, and the mass concentration after being dissolved in toluene to form a mixed system is 15 wt%. Then through the spinneret with the inner diameter of the tube head of 1mm, apply a voltage of 20KV, and spray the mixed system to the receiving plate 10cm away from the spinneret tube head (ie the source 4a, the drain 4b and the substrate between them). 1) On the surface. For the remaining steps of the method for preparing the active layer 5, reference may be made to Embodiment 1. Further, the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com