Silicon-based uniwafer photoelectricity integrated receiving chip for plastic optical fiber communication

A technology of optical fiber communication and optoelectronic integration, applied in optical fiber transmission, circuits, electrical components, etc., to achieve the effect of reducing cost, increasing bandwidth, and reducing junction capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

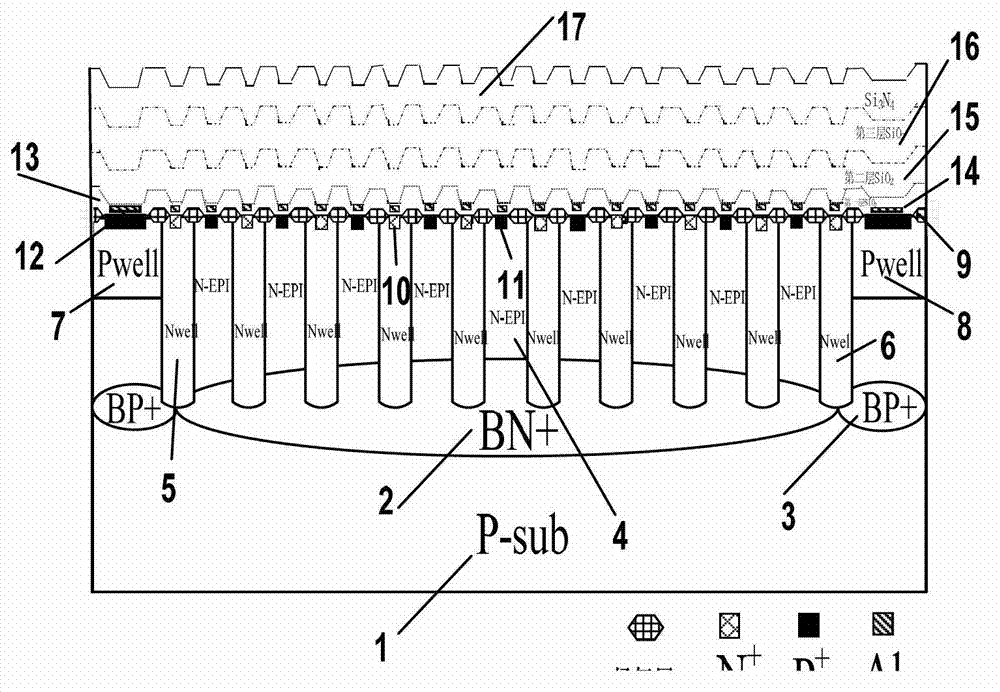

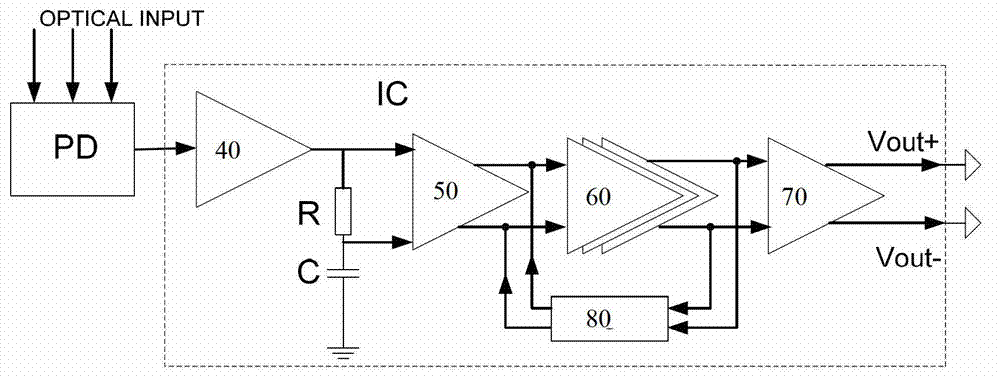

[0030] The silicon-based monolithic optoelectronic integrated receiving chip described in the embodiment of the present invention is prepared by a 0.5 μm standard BCD process, and is equipped with a silicon-based photodetector and a preamplifier integrated circuit.

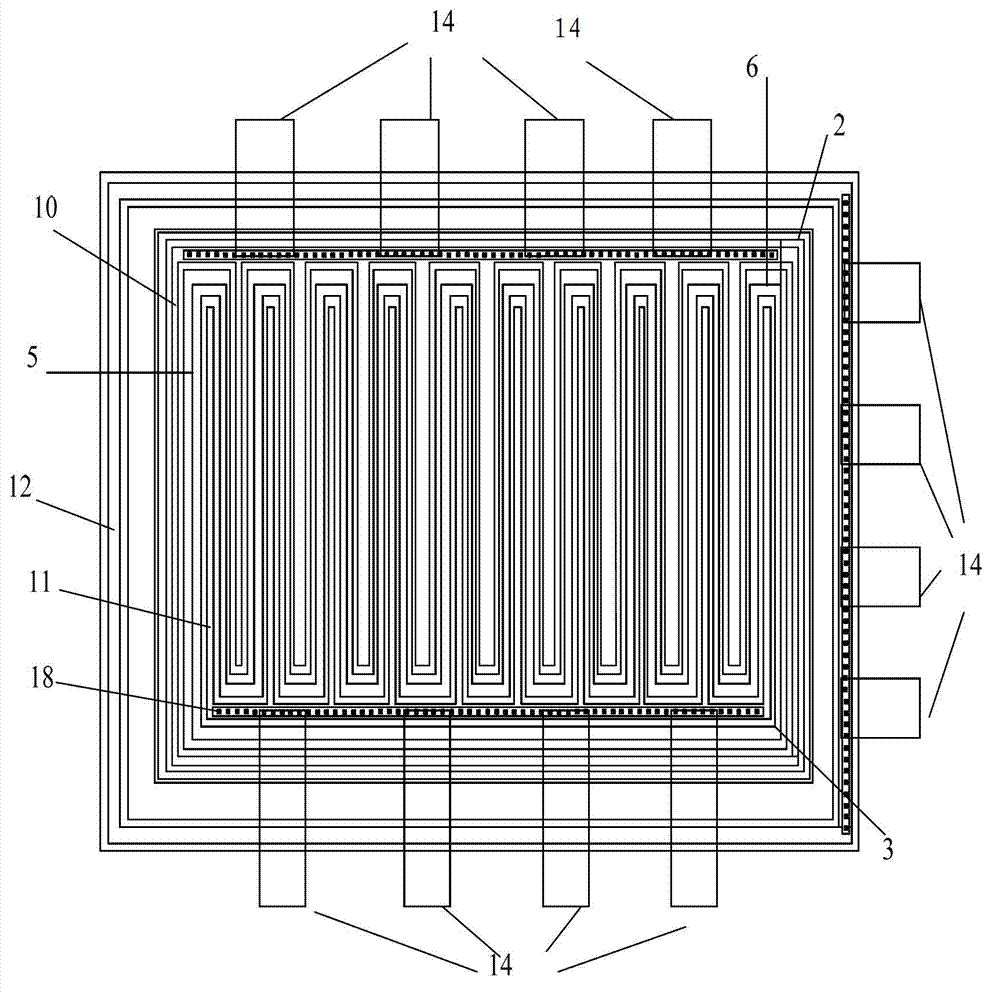

[0031] see figure 1 with 2 , the structure of the silicon-based photodetector and its manufacturing process are described as follows: First, the BN+ buried layer region is photolithographically etched on the high-resistance P-type silicon substrate 1, and the BN+ buried layer 2 and BP+ buried layer 2 are formed by ion implantation. Buried layer 3. N-EPI epitaxial layer 4 is grown on BN+buried layer 2 and BP+buried layer 3 . On the epitaxial layer 4, there are 11 N well regions with a distance of 14.6 μm and a width of 6.3 μm on the photolithography at equal intervals, and the 11 N wells are realized by ion implantation technology. Lithograph the P well area around the N wells 5 and 6, and use ion implantation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com