PCB (printed circuit board), laminating method for PCB and COF (chip on FPC (flexible printed circuit)), as well as liquid crystal display device

A liquid crystal display device, printed circuit board technology, applied in the structural connection of printed circuits, printed circuits, printed circuits, etc., can solve problems such as difficulty, failure to use normally, defective products, etc., to reduce deformation accumulation and improve connection accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

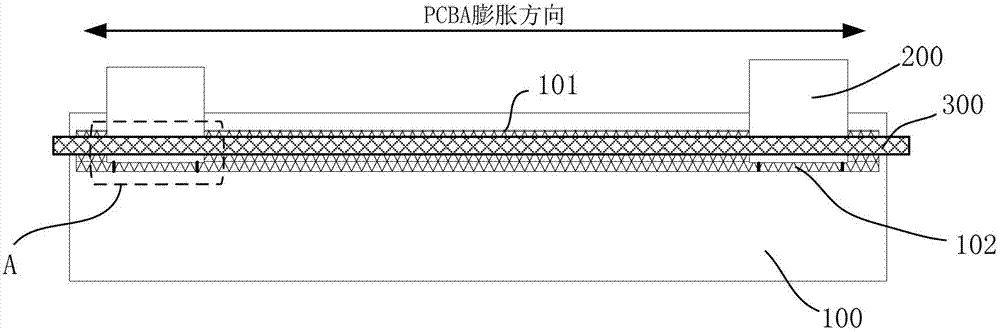

[0032] Such as Figure 5-Figure 9 As shown, the method for connecting the printed circuit board assembly 100 (PCBA) and the flexible circuit board 200 (COF) includes steps:

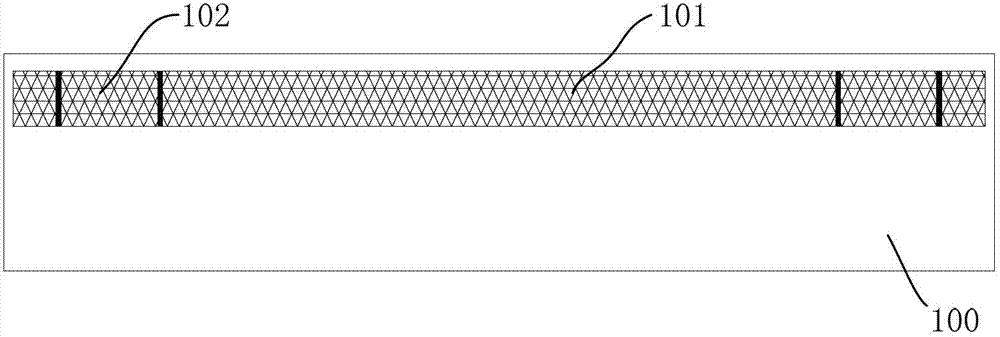

[0033] A. If Figure 5 As shown, avoidance grooves 120 are provided on one side or both sides of the pressing area 102 between the printed circuit board assembly 100 and the flexible circuit board 200 .

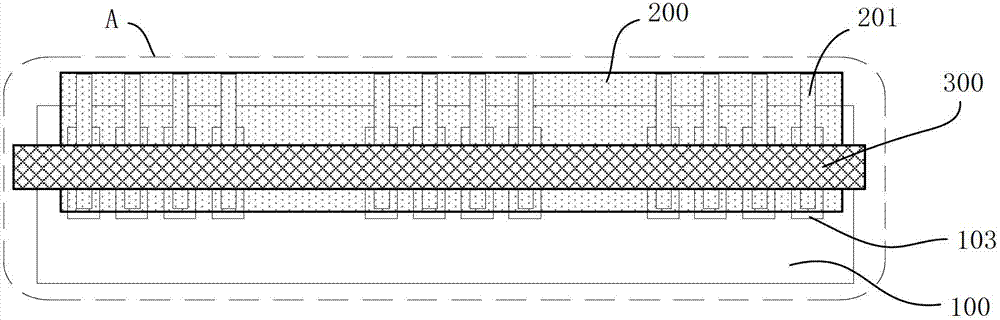

[0034] B. If Figure 6 As shown, the flexible circuit board 200 is bonded to the printed circuit board assembly 100 by using a high temperature bonding cutter head 300 so that the two are connected to the bonding area 102 .

[0035] In this embodiment, two pressing areas 102 are provided on the driving printed circuit board assembly 100 of the liquid crystal display device, and only one space-avoiding groove 120 is provided between two adjacent pressing-bonding areas, and the space-avoiding groove 120 It starts from the boundary of one pressing area 102 and ends at the boundary of another pressing are...

Embodiment 2

[0039] Such as Figure 10 As shown, the difference from the first embodiment is that two space-avoiding grooves 120 are provided between the two pressing areas 102, and the printed circuit board sheet is still reserved between the two space-avoiding grooves 120, so that the printed circuit board can be enlarged. In this way, the deformation of the printed circuit board sheet retained between the two avoidance grooves 120 can be prevented from accumulating to the pressing area 102 when it expands. The avoidance grooves 120 between the two press-fit regions 102 are all arranged on one side of the press-fit regions 102, and the other side of the press-fit regions 102 is also provided with the avoidance grooves 120, that is to say, each press-fit region 102 Evacuation grooves are provided on both sides of the two sides, and each relief groove 120 is terminated at the boundary of the adjacent pressing area 102 .

[0040] Such as Figure 11 As shown, although the reserved part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com