Reverse osmosis system

A technology of reverse osmosis and pressure exchanger, applied in the field of reverse osmosis system, can solve problems such as increased energy consumption and achieve the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

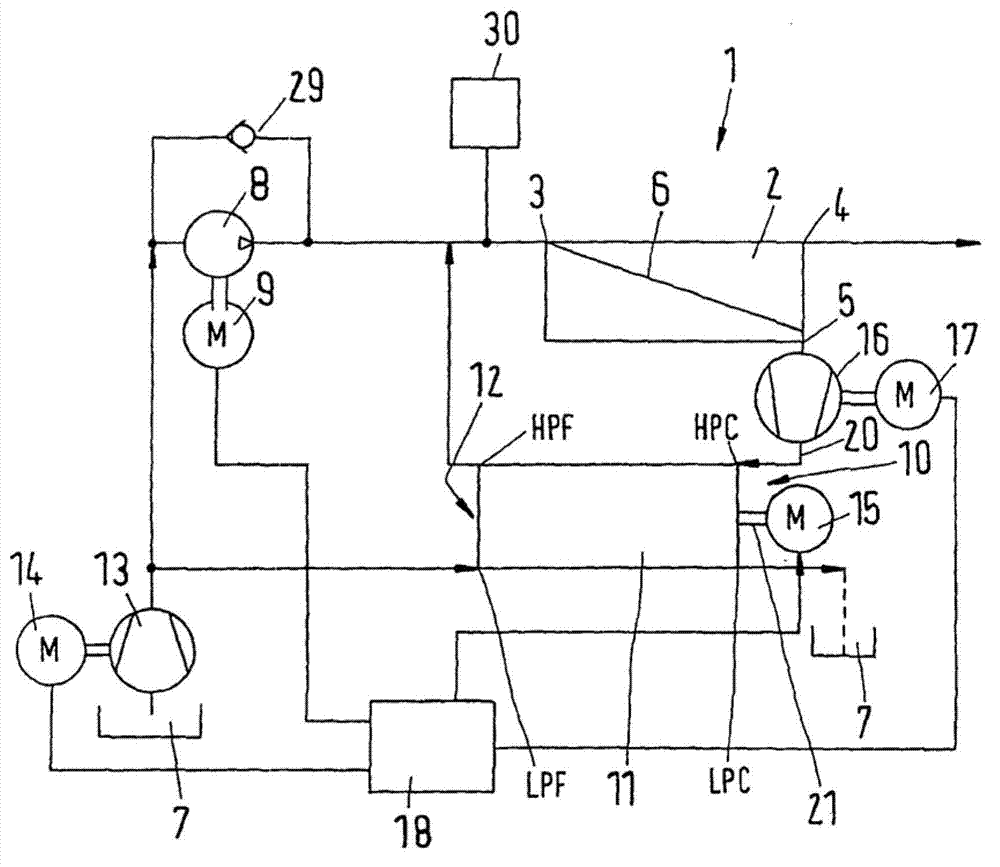

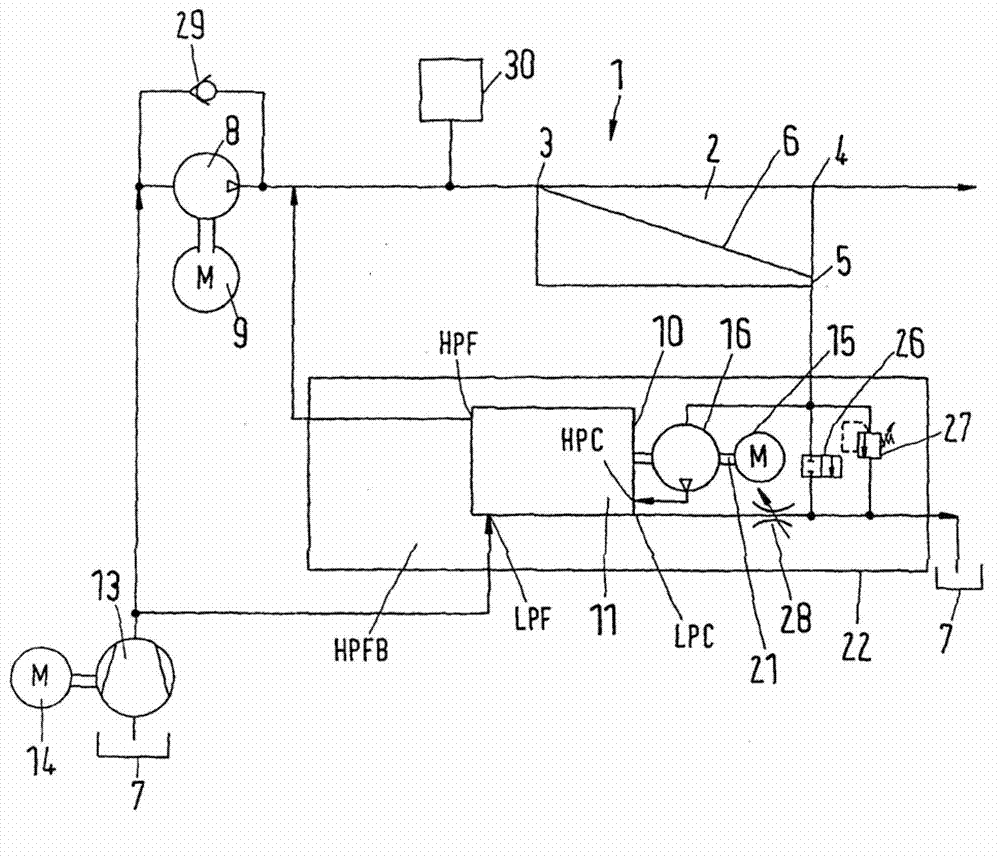

[0027] figure 1 is a schematic view of a reverse osmosis system 1, also known as a reverse osmosis plant or reverse osmosis plant.

[0028] The reverse osmosis system comprises a membrane unit 2 having an inlet 3 , a permeate outlet 4 and a concentrate outlet 5 . A membrane 6 is arranged between the inlet 3 and the permeate outlet 4 .

[0029] Of course, the membrane unit 2 can also have more than one inlet 3, one permeate outlet 4 and / or one concentrate outlet 5, and corresponding housings.

[0030] Via a high pressure pump 8 driven by a motor 9, the membrane unit 2 is supplied with feed water from a reservoir 7, eg the sea. The high-pressure pump 8 can be, for example, a piston pump. The motor 9 may be an electric motor controlled by a frequency converter. Thus, the high pressure pump 8 can be driven at variable speed and thus with variable delivery.

[0031] For reasons of simplification, the water from the reservoir 7 will be referred to simply as "feed water" in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com