Rectifying column start-up method

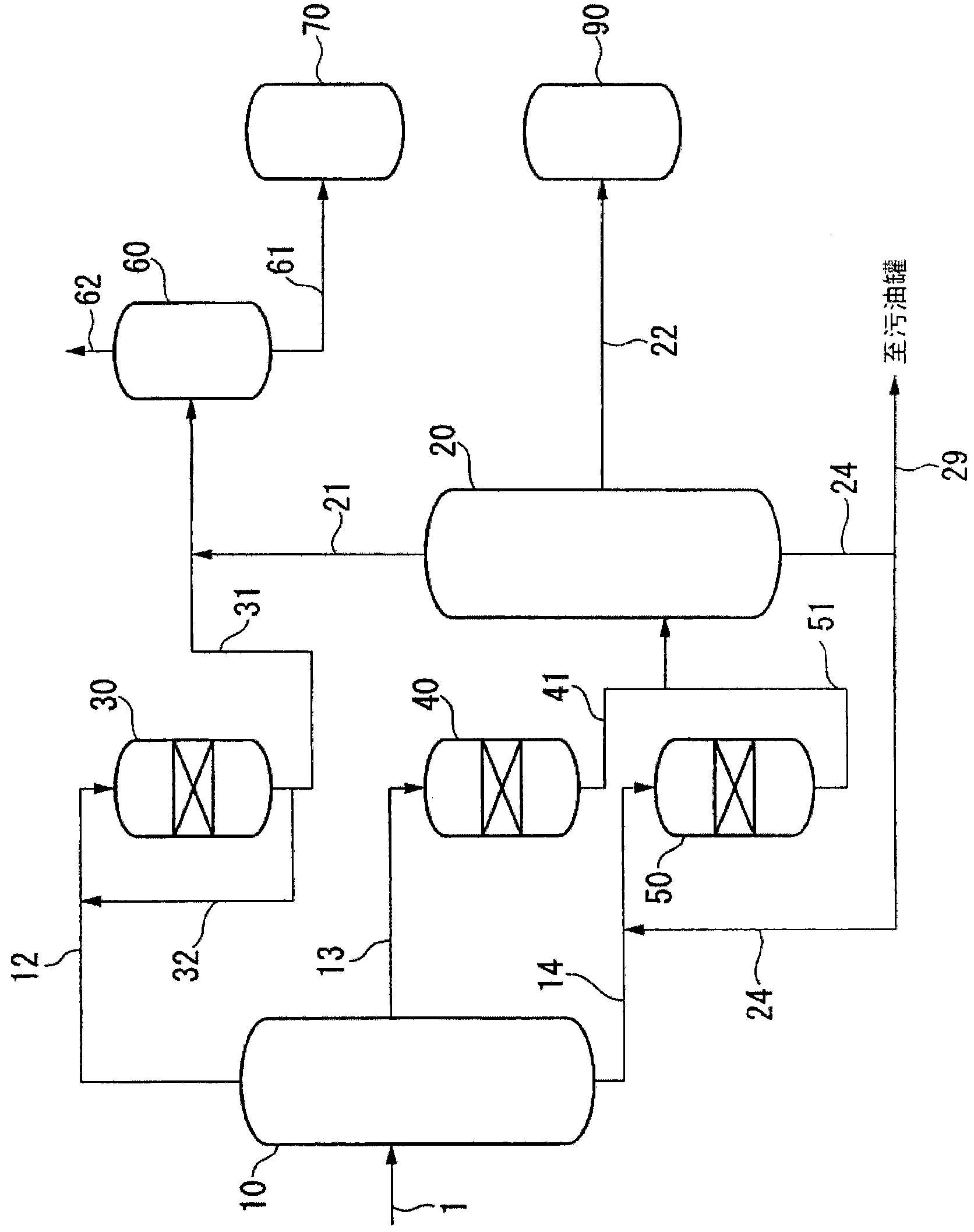

A rectifying tower and wax fraction technology are applied in the field of rectifying towers for hydrocracking products, and can solve problems such as blockage of the second rectifying tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

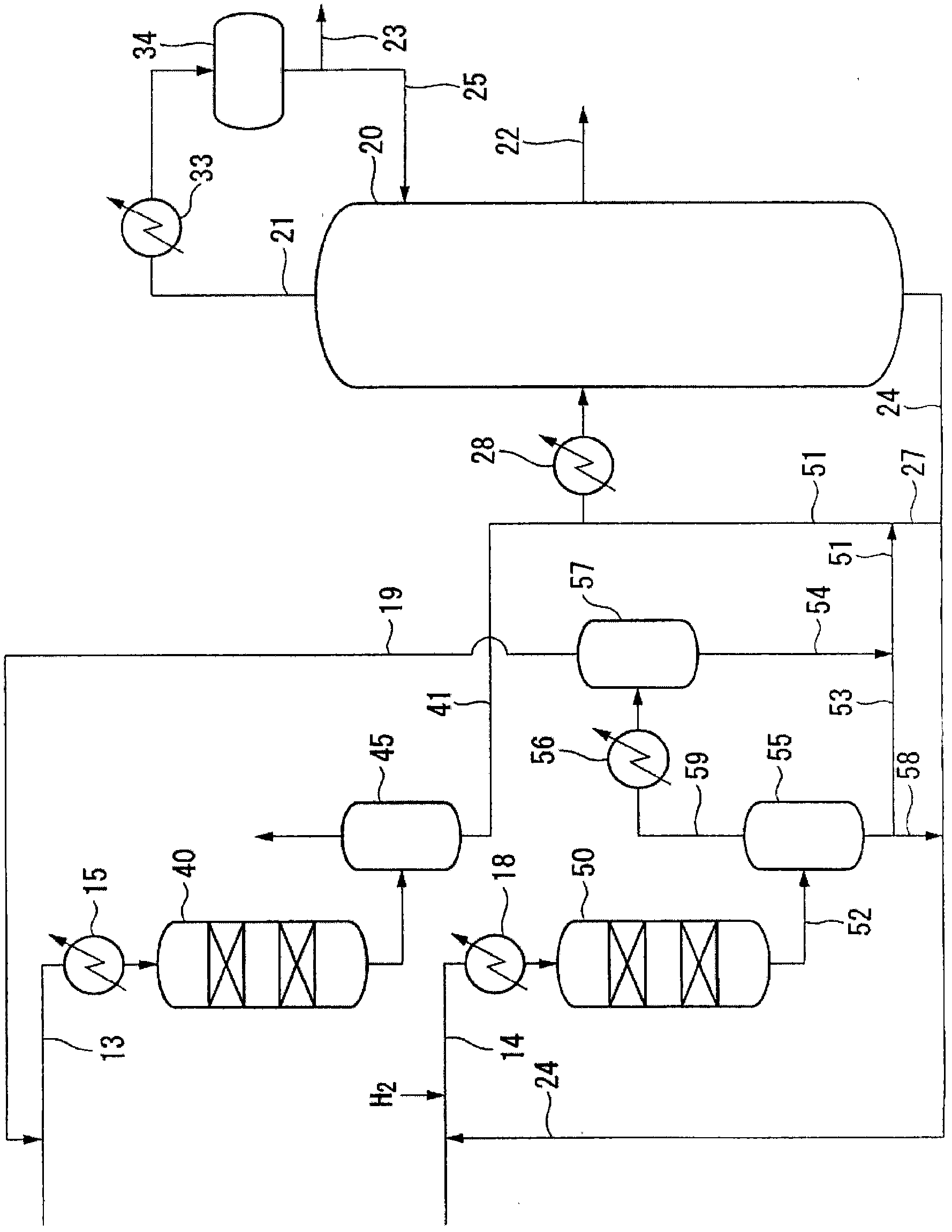

[0097] In the first embodiment, a hydrocarbon oil that is liquid at normal temperature and pressure and includes at least a part of the hydrocracked product of the wax fraction is used for preheating the second fractionator 20 at startup. Usually, the hydrocarbon oil is liquid at normal temperature and pressure, and therefore at least a part of the hydrocracked product needs to be liquid at normal temperature and pressure. The above-mentioned hydrocracked product may be produced and stored in the operation before the start-up operation, but it is preferable to start operation before the start-up of the second fractionator 20 and supply it from the wax fraction hydrocracking unit 50 in operation. Thereby, it is not necessary to install facilities for storing the hydrocracked product, and the facility cost can be reduced. Next, this first embodiment will be described in detail.

[0098] In the start-up of the second fractionator 20, first, the operation of the wax fraction hydr...

Embodiment 1

[0123] A mixture of USY zeolite with an average particle size of 0.82 μm (molar ratio of silica / alumina: 37), alumina-boria (mass ratio of alumina / boria: 5.6) and alumina base material (USY Zeolite / alumina-boria / alumina base material=4 / 56 / 40 (mass ratio)) was formed into a cylindrical shape with a diameter of about 1.5 mm and a length of about 3 mm by extrusion molding. The obtained molded body is dried and fired to obtain a carrier. The support was impregnated with an aqueous solution of chloroplatinic acid, and 0.6% by mass of platinum was supported as platinum atoms based on the mass of the support. By drying and firing this, a hydrocracking catalyst is obtained.

[0124] Next, the obtained hydrocracking catalyst is packed into a fixed-bed flow-through reactor, using figure 2 The apparatus shown in the figure hydrocracks a crude wax fraction (having 21 to 80 carbon atoms and 95% by mass of normal paraffins) obtained by fractional distillation of FT synthetic oil.

[012...

Embodiment 2

[0132] Set the reaction temperature of the wax fraction hydrocracking unit 50 to 320°C, and set the LHSV from 0.7h to -1 to 2.0h -1 Gradually rise, the valve (not shown) provided in the pipeline 53 is closed, the liquid component obtained from the first gas-liquid separation device 55 is recycled to the wax fraction hydrocracking device 50 through the pipeline 58 and the pipeline 24, and only the The liquid component obtained by the second gas-liquid separation device 57 is supplied to the second rectification column 20 through the lines 54, 51 and the heat exchanger 28, and the second rectification column 20 is carried out by the same operation as in Example 1 except that start. In addition, the hydrocarbon oil obtained from the second gas-liquid separator 57 was extracted through the line 51, and the pour point was measured, which was -17.5°C.

[0133] Furthermore, the start-up of the second fractionator 20 was completed without causing problems such as clogging due to sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com