Curing agent for furan resin self-hardening sand for casting and preparation method thereof

A technology of furan resin and no-bake sand, which is applied in casting molding equipment, casting molds, manufacturing tools, etc. It can solve the problem of narrow range of total acidity of benzene sulfonic acid curing agent, difficulty in increasing the total acidity of curing agent, and difficulty in guaranteeing product quality, etc. problem, achieve the effect of reducing consumption cost, high initial strength and final strength, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

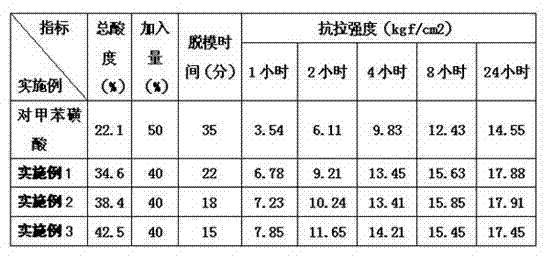

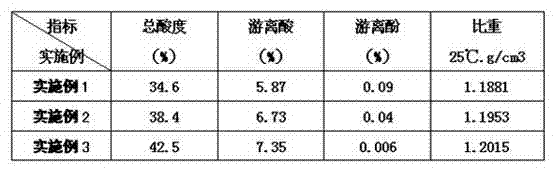

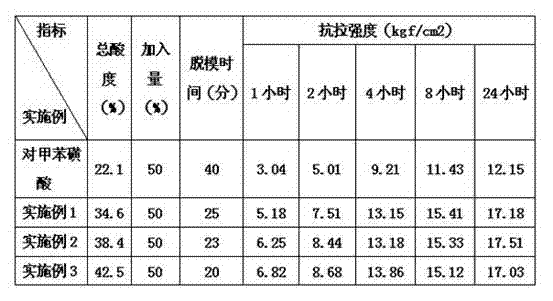

[0030] Example one:

[0031] In this embodiment, a 1000L enamel reactor is used. In parts by weight, the curing agent for furan resin self-hardening sand for casting described in this embodiment is composed of the following components:

[0032] Phenol 200, sulfuric acid 250, methanol 150,

[0033] Maleic anhydride 50, water 300.

[0034] The preparation method of the above-mentioned curing agent for furan resin self-hardening sand for casting includes the following steps:

[0035] (1) Pump the melted phenol into the reaction kettle, slowly add sulfuric acid while stirring, and control the feeding temperature at ≤90℃; after the sulfuric acid is added, control the material temperature at 95~100℃ to cause sulfonation reaction 1.5 hours;

[0036] (2) After the sulfonation reaction time is up, reduce the material temperature to below 75°C, slowly add methanol to carry out the esterification reaction, the reaction temperature is 70-75°C, and the esterification time is 1 hour;

[0037] (3) Afte...

Example Embodiment

[0039] Embodiment two:

[0040] In this embodiment, a 1000L enamel reactor is used. In parts by weight, the curing agent for furan resin self-hardening sand for casting described in this embodiment is composed of the following components:

[0041] Phenol 250, sulfuric acid 425, methanol 175,

[0042] Maleic anhydride 35, water 400.

[0043] The preparation method of the above-mentioned curing agent for furan resin self-hardening sand for casting includes the following steps:

[0044] (1) Pump the melted phenol into the reaction kettle, slowly add sulfuric acid while stirring, and control the feeding temperature at ≤90℃; after the sulfuric acid is added, control the material temperature at 95~100℃ to cause sulfonation reaction 2 hours;

[0045] (2) After the sulfonation reaction time is up, reduce the material temperature to below 75°C, slowly add methanol to carry out the esterification reaction, the reaction temperature is 70-90°C, and the esterification time is 2 hours;

[0046] (3) Af...

Example Embodiment

[0048] Embodiment three:

[0049] In this embodiment, a 2000L enamel reactor is used. In parts by weight, the curing agent for furan resin self-hardening sand for casting described in this embodiment is composed of the following components:

[0050] Phenol 300, sulfuric acid 940, methanol 200,

[0051] Maleic anhydride 25, water 500.

[0052] The preparation method of the above-mentioned curing agent for furan resin self-hardening sand for casting includes the following steps:

[0053] (1) Pump the melted phenol into the reaction kettle, slowly add sulfuric acid while stirring, and control the feeding temperature at ≤90℃. After the sulfuric acid is added, the temperature of the material is controlled at 95~100℃ for sulfonation reaction for 3 hours;

[0054] (2) After the sulfonation reaction time is up, lower the material temperature to below 75°C, slowly add methanol to carry out the esterification reaction, the reaction temperature is 70-75°C, and the esterification time is 2 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com